This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

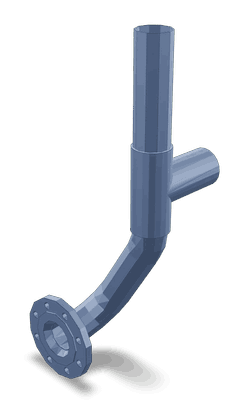

The Exhaust Transfer Connection, part number 4011628, is a component manufactured by Cummins for use in commercial truck operations. Cummins, a prominent name in the automotive industry, produces this part to enhance the functionality and efficiency of truck exhaust systems. This component is integral to maintaining optimal engine performance and ensuring compliance with emissions standards.

Basic Concepts of Exhaust Transfer Connection

An Exhaust Transfer Connection is a component within the exhaust system that facilitates the transfer of exhaust gases from the engine to the exhaust pipe. Its function is to direct the flow of these gases efficiently, which contributes to the overall performance of the engine and helps in controlling emissions. By ensuring a smooth and unobstructed path for exhaust gases, this part plays a role in reducing backpressure and enhancing engine efficiency 1.

Purpose of the Exhaust Transfer Connection

The Exhaust Transfer Connection is designed to direct the flow of exhaust gases, which helps in reducing backpressure within the exhaust system. This reduction in backpressure allows the engine to expel exhaust gases more efficiently, which can lead to improved engine performance. Additionally, by ensuring a smooth flow of exhaust gases, this part contributes to the overall efficiency of the engine 2.

Key Features

The Exhaust Transfer Connection is characterized by several key features. Its design is engineered to facilitate efficient exhaust gas flow, with specific connection points that ensure a secure fit within the exhaust system. The materials used in its construction are chosen for their durability and resistance to the high temperatures and corrosive environments typical of exhaust systems. Unique attributes of this part may include specialized coatings or designs that enhance its performance and longevity 3.

Benefits

The advantages provided by the Exhaust Transfer Connection include improved exhaust flow, which can lead to reduced emissions and enhanced fuel efficiency. By ensuring that exhaust gases are expelled efficiently, this part can contribute to potential increases in engine power and torque. Additionally, its design and materials contribute to its durability and resistance to the harsh conditions within the exhaust system 4.

Installation Process

Proper installation of the Exhaust Transfer Connection involves several steps. Initially, any necessary tools and replacement parts should be gathered. Preparatory steps may include cleaning the connection points within the exhaust system to ensure a secure fit. The part should be positioned correctly within the system, with all connection points secured to prevent leaks. Ensuring a secure and correct fit is vital for the part’s performance and the overall efficiency of the exhaust system 5.

Common Issues and Troubleshooting

Typical problems that may arise with the Exhaust Transfer Connection include leaks, corrosion, or blockages. Leaks can often be identified by unusual noises or a decrease in engine performance, and may require re-sealing or replacement of the part. Corrosion can be addressed through cleaning and the application of protective coatings. Blockages may necessitate disassembly and cleaning of the exhaust system. Regular inspections can help in identifying these issues early, allowing for timely intervention 6.

Maintenance Tips

To ensure the longevity and optimal performance of the Exhaust Transfer Connection, regular maintenance practices are recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the part and the surrounding exhaust system can prevent buildup that may lead to blockages. When significant wear or damage is observed, consideration should be given to replacing the part to maintain the efficiency of the exhaust system 7.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to innovation and quality in automotive component manufacturing. With a rich history and a diverse product range, Cummins has established a reputation for producing reliable and high-performance parts. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a trusted name in the industry 8.

Compatibility with Cummins Engines

The Exhaust Transfer Connection part 4011628 is specifically engineered to fit seamlessly with the QSV81G and QSV91G engines. These engines are part of Cummins’ robust lineup, known for their reliability and performance in various applications. The part’s design ensures a secure and leak-free connection, which is crucial for maintaining optimal engine performance and efficiency 9.

Installation and Functionality

The installation of the Exhaust Transfer Connection part 4011628 in the QSV81G and QSV91G engines is straightforward, thanks to its precise engineering. This part is designed to fit snugly with the engine’s exhaust ports, ensuring a tight seal that prevents exhaust leaks. The connection is critical for the efficient transfer of exhaust gases, which helps in reducing back pressure and enhancing engine performance 10.

Maintenance and Reliability

Regular maintenance of the Exhaust Transfer Connection part 4011628 is essential to ensure its longevity and performance. Cummins has designed this part to be durable and resistant to the harsh conditions of the exhaust system. Proper installation and maintenance can help in avoiding potential issues such as leaks or failures, which can lead to decreased engine efficiency and increased emissions 11.

Role of Part 4011628 Exhaust Transfer Connection in Engine Systems

The Exhaust Transfer Connection, identified by part number 4011628, is integral to the efficient operation of various engine systems. This component facilitates the seamless transfer of exhaust gases from the engine to the exhaust system, ensuring optimal performance and emissions control.

Integration with Fuel Control Module

The Exhaust Transfer Connection works in conjunction with the Fuel Control Module to maintain the engine’s air-fuel ratio. By efficiently routing exhaust gases, it helps the Fuel Control Module to adjust fuel delivery in real-time, enhancing combustion efficiency and reducing emissions 12.

Interaction with Gas Pipes

In systems utilizing gas pipes, the Exhaust Transfer Connection ensures that exhaust gases are properly directed away from the engine. This is particularly important in high-pressure environments where gas pipes operate, as it prevents backpressure that could otherwise hinder engine performance 13.

Coordination with Assemblies (Assy)

When integrated with assemblies, such as the Gas Module P=1, the Exhaust Transfer Connection plays a role in maintaining consistent gas flow. This is essential for the assembly’s function, ensuring that gas is delivered at the correct pressure and temperature for efficient engine operation 14.

Function within Gas Modules

For Gas Modules operating at different pressures (e.g., P=1, 25bar; P=1, 8bar; P=3bar), the Exhaust Transfer Connection is vital. It ensures that exhaust gases are expelled efficiently, allowing these modules to maintain their specified pressure levels without interference 15.

Synergy with Module Gas

In systems where a Module Gas is present, the Exhaust Transfer Connection aids in the regulation of gas flow. This synergy ensures that the module can operate within its designed parameters, contributing to overall engine efficiency and reliability 16.

Role in High-Pressure Gas Modules

For high-pressure Gas Modules, such as those operating at 3 bar, the Exhaust Transfer Connection is particularly important. It ensures that exhaust gases are expelled with minimal resistance, allowing the module to maintain high-pressure conditions necessary for optimal performance 17.

Conclusion

In summary, the Exhaust Transfer Connection (part 4011628) is a key component in various engine systems, enhancing the functionality and efficiency of fuel control modules, gas pipes, assemblies, and gas modules across different pressure ranges. Its role in maintaining optimal engine performance and emissions control underscores its importance in modern engine systems.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Service Manual (5676978).

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Cummins Inc. (n.d.). Service Manual (5676978).

↩ -

Cummins Inc. (n.d.). Service Manual (5676978).

↩ -

Cummins Inc. (n.d.). Service Manual (5676978).

↩ -

Cummins Inc. (n.d.). Service Manual (5676978).

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Service Manual (5676978).

↩ -

Cummins Inc. (n.d.). Service Manual (5676978).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.