191984

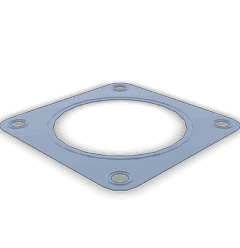

Exhaust Outlet Connection Gasket

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Outlet Connection Gasket, identified by Part #191984, is a component manufactured by Cummins, a reputable name in the automotive and heavy-duty truck industry. This gasket plays a role in the exhaust systems of heavy-duty truck engines, ensuring the integrity and efficiency of the exhaust flow.

Function and Operation

The Exhaust Outlet Connection Gasket operates within the exhaust system by sealing the connection between the exhaust manifold and the exhaust pipe. This seal is vital for maintaining the pressure and flow of exhaust gases as they exit the engine. The gasket’s placement and design allow it to withstand high temperatures and pressures, ensuring a consistent seal under varying engine conditions 1.

Purpose of the Exhaust Outlet Connection Gasket

The primary purpose of the Exhaust Outlet Connection Gasket is to maintain a seal that prevents exhaust leaks. By doing so, it ensures efficient exhaust flow, which is important for the engine’s performance and emissions control. A properly sealed exhaust system contributes to the engine’s overall efficiency and helps in meeting emissions standards 2.

Key Features

The Exhaust Outlet Connection Gasket is designed with specific features to enhance its performance and durability. It is typically made from materials that can withstand high temperatures and pressures, such as graphite or metal. The design of the gasket may include features like splines or grooves to ensure a tight fit and prevent shifting. These characteristics contribute to the gasket’s ability to maintain a reliable seal over time 3.

Benefits

The use of the Exhaust Outlet Connection Gasket offers several benefits. It contributes to improved engine efficiency by ensuring that exhaust gases are directed properly, reducing the risk of backpressure. This efficient exhaust flow can lead to better fuel economy and performance. Additionally, a well-sealed exhaust system helps in reducing emissions, aligning with environmental regulations. The durability of the gasket also enhances the overall reliability of the engine.

Installation and Maintenance

Proper installation of the Exhaust Outlet Connection Gasket is crucial for its effectiveness. It should be installed according to the manufacturer’s torque specifications to ensure a proper seal without over-tightening, which could damage the gasket or the mating surfaces. Regular maintenance checks are recommended to ensure the gasket remains in good condition, as wear or damage can lead to leaks and reduced efficiency.

Troubleshooting Common Issues

Common issues with the Exhaust Outlet Connection Gasket include leaks or failure due to wear, improper installation, or exposure to extreme conditions. Troubleshooting these issues involves inspecting the gasket for signs of wear or damage, checking the tightness of the connection, and ensuring that the mating surfaces are clean and free of debris. Addressing these issues promptly can prevent more significant problems and maintain the efficiency of the exhaust system.

Cummins Overview

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its high-quality components and innovative solutions. With a history of providing reliable and durable parts, Cummins has built a reputation for excellence and commitment to customer satisfaction. Their products, including the Exhaust Outlet Connection Gasket, are designed with precision and engineered to meet the demanding requirements of heavy-duty applications.

Role of Part 191984 Exhaust Outlet Connection Gasket in Engine Systems

The Exhaust Outlet Connection Gasket, part number 191984, serves as a vital interface in the engine system, ensuring a secure and efficient connection between various components. Its primary function is to create a seal that prevents exhaust gases from leaking, thereby maintaining the system’s integrity and performance.

Integration with Collector Mounting

When integrating with the collector mounting, the gasket ensures that the connection between the exhaust manifold and the collector is airtight. This is essential for directing exhaust gases efficiently from the manifold to the collector, minimizing the risk of leaks that could reduce engine performance and increase emissions.

Role in Exhaust Manifold Sub-Option

In configurations where an exhaust manifold sub-option is utilized, the gasket plays a key role in sealing the connection points. This is particularly important in systems with multiple exhaust paths or those designed for specific performance enhancements. The gasket ensures that each sub-option component is securely sealed, contributing to consistent exhaust flow and reduced noise.

Sealing the Manifold and Exhaust System

The gasket is positioned between the manifold and the exhaust system, creating a barrier that prevents exhaust gases from escaping. This seal is vital for maintaining the pressure within the exhaust system, which is necessary for optimal turbocharger performance and overall engine efficiency.

Turbocharger and Turbocharger Location

At the turbocharger location, the gasket ensures a tight seal between the exhaust manifold and the turbocharger inlet. This is important for maximizing the efficiency of the turbocharger, as any leak in this area can result in a loss of boost pressure and reduced engine performance. The gasket helps maintain the necessary pressure differential for effective turbocharging.

Turbo Location and Turo Location

In systems where the turbocharger is positioned at a specific turbo location or turo location, the gasket ensures that the connection between the exhaust components and the turbocharger remains sealed. This is essential for consistent turbocharger operation and for preventing any backflow of exhaust gases, which could compromise engine performance and efficiency.

Overall System Integrity

Across all these applications, the Exhaust Outlet Connection Gasket, part number 191984, ensures that the various components of the exhaust system work in harmony. By providing a reliable seal, it contributes to the overall efficiency and performance of the engine, ensuring that exhaust gases are directed properly and that the system operates within designed parameters.

Conclusion

The Exhaust Outlet Connection Gasket, part number 191984, is a critical component in the exhaust systems of heavy-duty truck engines. Its role in maintaining a secure seal between the exhaust manifold and the exhaust pipe is essential for efficient exhaust flow, engine performance, and emissions control. Proper installation, regular maintenance, and prompt troubleshooting of common issues are key to ensuring the gasket’s effectiveness and the overall reliability of the engine system.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.