This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

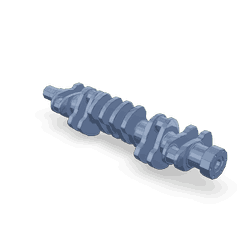

The Cummins 3608833 Engine Crankshaft is a critical component in commercial truck engines, essential for the engine’s operation. This crankshaft is engineered to endure the rigorous demands of heavy-duty applications, ensuring consistent performance and efficiency in truck engines.

Basic Concepts of Engine Crankshafts

An engine crankshaft is a mechanical component that transforms the linear motion of the pistons into rotational motion, which is then utilized to propel the vehicle. In an internal combustion engine, the crankshaft is linked to the pistons through connecting rods. As the pistons move up and down due to combustion, the crankshaft rotates, transmitting power to the transmission and ultimately to the wheels 1.

Purpose of the Cummins 3608833 Engine Crankshaft

The Cummins 3608833 Engine Crankshaft is specifically designed to function within the stringent parameters of commercial truck engines. It interacts with various engine components, including the pistons, connecting rods, and the flywheel, to facilitate smooth and efficient engine operation. Its design allows for the effective transfer of power generated by the combustion process to the rest of the drivetrain.

Key Features

This Cummins part boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and fatigue under high stress conditions. The design incorporates precise balancing to minimize vibrations, contributing to smoother engine operation. Additionally, the crankshaft features advanced machining techniques that improve its overall efficiency and reliability 2.

Benefits

The Cummins 3608833 Engine Crankshaft offers several benefits, including improved engine efficiency, enhanced reliability, and increased longevity. Its robust construction and precise engineering contribute to reduced maintenance requirements and extended service life, making it a valuable component for commercial truck engines.

Installation Process

Installing the Cummins 3608833 Engine Crankshaft requires careful attention to detail and the use of appropriate tools. The process involves removing the old crankshaft, inspecting the engine block for any damage, and then fitting the new crankshaft into place. It is important to ensure proper alignment and torque specifications are met during installation to guarantee optimal performance and safety 3.

Troubleshooting Common Issues

Common issues associated with engine crankshafts can include wear, misalignment, and damage from debris. Diagnosing these problems often involves visual inspection, measurement of clearances, and analysis of engine performance data. Recommended solutions may include resurfacing, realignment, or replacement of the crankshaft, depending on the severity of the issue 4.

Maintenance Tips

To ensure the Cummins 3608833 Engine Crankshaft operates at peak performance, regular maintenance is essential. This includes periodic inspections for signs of wear or damage, ensuring proper lubrication, and following manufacturer-recommended service intervals. Adhering to these practices helps maintain the crankshaft’s integrity and contributes to the overall efficiency and reliability of the engine.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and efficient engine components. The company’s extensive product range and commitment to innovation have made it a preferred choice for commercial vehicle manufacturers and operators worldwide.

Engine Crankshaft Compatibility with Cummins Part 3608833

The Cummins part 3608833, an Engine Crankshaft, is designed to fit into a variety of engine models. Here’s a detailed look at its compatibility across different engine types:

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

The G855 series engines, including the G855, G855 CM558, and GTA855 CM558 (CM2358) G101, are compatible with the Cummins part 3608833. This crankshaft is engineered to handle the specific demands of these engines, ensuring smooth operation and durability.

N14 Series

- N14 CELECT

- N14 G

- N14 MECHANICAL

The N14 series engines, such as the N14 CELECT, N14 G, and N14 MECHANICAL, also utilize the Cummins part 3608833. This crankshaft is tailored to meet the performance requirements of these engines, providing reliable power and longevity.

NH/NT 855 Series

- NH/NT 855

The NH/NT 855 engine is another model that is compatible with the Cummins part 3608833. This crankshaft is designed to integrate seamlessly with the NH/NT 855, ensuring optimal engine performance.

QSNT14 Series

- QSNT14 CM876 N102

The QSNT14 CM876 N102 engine is also compatible with the Cummins part 3608833. This crankshaft is specifically engineered to fit this engine model, ensuring that it operates efficiently and reliably.

Role of Part 3608833 Engine Crankshaft in Engine Systems

The engine crankshaft, specifically part 3608833, is a fundamental component that interacts with various engine systems to ensure efficient operation. It is integral to the conversion of linear piston motion into rotational force, which is then transmitted to the transmission system.

Interaction with Base Parts and Engine Block

The crankshaft is mounted within the engine block, a structure that houses the cylinders and provides a rigid framework for the engine’s components. The precise alignment of the crankshaft within the block is essential for the smooth operation of the engine. The base parts, which include bearings and seals, support the crankshaft and reduce friction as it rotates.

Integration with Cylinder and Short Block

In the cylinder short block configuration, the crankshaft works in tandem with the pistons housed within the cylinders. As the pistons move up and down due to combustion, the connecting rods transfer this motion to the crankshaft, causing it to rotate. This rotation is consistent and balanced, thanks to the crankshaft’s design, which includes counterweights to offset the forces generated by the pistons.

Role in Short Block Assembly Kit and Short Block Kit

When considering the short block assembly kit or the short block kit, the crankshaft is a key element. These kits typically include the engine block, crankshaft, pistons, and connecting rods. The crankshaft’s role is to integrate these components into a functional unit, ensuring that the engine can generate power efficiently.

Function within EBM: Block, Engine

In the context of an EBM (Engine Block Module): Block, Engine setup, the crankshaft is central to the engine’s operation. It not only converts the linear motion of the pistons into rotational motion but also helps in maintaining the engine’s balance and reducing vibrations. This is particularly important in high-performance engines where precision and smoothness are paramount.

Contribution to Short Assembly Block and Short Block

The short assembly block and the short block both rely on the crankshaft to facilitate the primary mechanical motion within the engine. The crankshaft’s journals interact with the main bearings, which are housed within the engine block, to ensure smooth rotation and durability under high loads and RPMs.

Conclusion

In summary, part 3608833 Engine Crankshaft is a pivotal component that interfaces with various engine systems, including the engine block, cylinders, and short block assemblies, to convert piston motion into rotational force, which is essential for the engine’s operation.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Klyde, Michael and VanGelder, Kirk. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.