This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

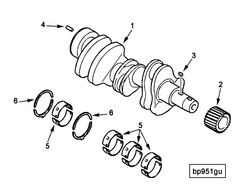

The Cummins 4900901 Engine Crankshaft is a critical component in heavy-duty trucks, essential for the engine’s operation. This part is engineered to endure the demanding conditions of heavy-duty applications, ensuring reliable performance and efficiency.

Basic Concepts of Engine Crankshafts

An engine crankshaft converts the linear motion of the pistons into rotational motion, which drives the vehicle’s wheels. It operates within an internal combustion engine, working in conjunction with other components to facilitate the engine’s operation 1.

Purpose of the 4900901 Engine Crankshaft

The 4900901 Engine Crankshaft is integral to the operation of a truck’s engine. It converts the linear motion of the pistons into rotational motion, which is then transmitted to the transmission and ultimately to the wheels. This conversion is fundamental to the engine’s ability to produce power and propel the vehicle 2.

Key Features

This Cummins part boasts several key features that enhance its performance and durability. Its design incorporates high-quality materials, such as forged steel, which provide strength and resilience under high stress. Additionally, precision machining ensures optimal balance and smooth operation, contributing to the crankshaft’s longevity and reliability.

Benefits

The 4900901 Engine Crankshaft offers numerous benefits, including improved engine efficiency, reliability, and performance in heavy-duty applications. Its robust construction and precise engineering allow it to withstand the rigors of heavy-duty use, ensuring consistent performance and longevity.

Construction and Design

The construction and design of the 4900901 Engine Crankshaft involve a meticulous manufacturing process. Forged from high-quality steel, the crankshaft undergoes precision machining to achieve the necessary balance and smoothness. Engineering considerations include factors such as stress distribution, material properties, and dimensional accuracy to ensure optimal performance and durability 3.

Installation Process

Installing the 4900901 Engine Crankshaft requires careful attention to detail and the use of appropriate tools. The process involves aligning the crankshaft with the engine block, securing it in place, and ensuring proper clearance with other components. Special tools may be required to achieve precise alignment and torque specifications.

Common Issues and Troubleshooting

Common issues associated with engine crankshafts include wear, misalignment, and imbalance. Symptoms to watch for include unusual noises, vibrations, or a decrease in engine performance. Troubleshooting steps may involve inspecting the crankshaft for signs of wear, checking alignment, and balancing the crankshaft to resolve any issues.

Maintenance Tips

Maintaining the 4900901 Engine Crankshaft is crucial for ensuring its longevity and performance. Regular inspection intervals should be observed to check for signs of wear or damage. Proper lubrication is also essential to reduce friction and wear. Following best practices for maintenance can help prolong the service life of the crankshaft.

Performance Enhancements

Potential performance enhancements for the 4900901 Engine Crankshaft may include modifications to increase power output or efficiency. These enhancements could involve upgrading materials, optimizing the design, or implementing advanced manufacturing techniques to improve the crankshaft’s performance characteristics.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation for producing high-quality engine components. Founded in 1919, Cummins has established itself as a leader in the industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product lineup includes a wide range of engine components designed to meet the demands of various applications, from heavy-duty trucks to industrial equipment 4.

Cummins Engine Crankshaft 4900901 Compatibility

The Cummins Engine Crankshaft part number 4900901 is a critical component designed to fit seamlessly within various Cummins engine models. This crankshaft is engineered to ensure optimal performance and durability, making it a suitable choice for several engine configurations.

Engine Compatibility

- A1400 Engines

- The Cummins Engine Crankshaft 4900901 is specifically designed to fit within the A1400 engine series. This compatibility ensures that the crankshaft can handle the specific demands of the A1400 engine, providing reliable operation and longevity.

Grouping of Engine Models

- Cummins Engine Series

- The 4900901 crankshaft is part of a broader range of crankshafts offered by Cummins, which are tailored to fit various engine models within their series. This part is engineered to meet the stringent requirements of Cummins engines, ensuring that it integrates smoothly with other engine components.

Key Considerations

-

Precision Engineering

- The design of the 4900901 crankshaft emphasizes precision engineering, which is crucial for maintaining the balance and efficiency of the engine. This precision ensures that the crankshaft can withstand the stresses of engine operation without compromising performance.

-

Material Quality

- The material used in the construction of the 4900901 crankshaft is of high quality, contributing to its durability and resistance to wear. This quality is essential for ensuring that the crankshaft can perform reliably over an extended period.

-

Compatibility with Other Parts

- The 4900901 crankshaft is designed to work in conjunction with other engine parts, ensuring that it fits perfectly within the engine assembly. This compatibility is crucial for maintaining the overall integrity of the engine.

Role of Part 4900901 Engine Crankshaft in Engine Systems

The part 4900901 Engine Crankshaft is integral to the operation of various engine systems. It transforms the reciprocating motion of the pistons into rotational motion, which is then transmitted to the transmission system via the flywheel. This rotational motion is essential for the operation of several components within the engine.

Interaction with the Piston and Connecting Rod Assembly

The crankshaft works in conjunction with the piston and connecting rod assembly. As the pistons move up and down within the cylinders, the connecting rods transfer this linear motion to the crankshaft. The crankshaft’s journals, where the connecting rods attach, convert this motion into a smooth rotational force.

Relationship with the Flywheel

Connected to the rear of the crankshaft, the flywheel plays a significant role in maintaining the engine’s momentum. The crankshaft transmits rotational energy to the flywheel, which helps in stabilizing the engine’s operation by smoothing out the power delivery between combustion cycles.

Connection to the Timing Chain or Belt

The crankshaft is also linked to the camshaft via the timing chain or belt. This connection ensures that the valves open and close in sync with the pistons’ movements. Proper timing is essential for the engine’s efficient operation, and the crankshaft’s consistent rotation is key to maintaining this timing.

Role in the Lubrication System

The crankshaft relies on the engine’s lubrication system to reduce friction and wear. Oil is supplied to the crankshaft’s main and rod bearings through drilled passages within the crankshaft itself. This lubrication is vital for the crankshaft’s longevity and the engine’s overall performance.

Impact on the Vibration Dampener

Mounted at the front of the crankshaft, the vibration dampener (or harmonic balancer) reduces vibrations caused by the engine’s operation. The crankshaft’s smooth rotation is crucial for the effective functioning of the dampener, which helps in maintaining a stable engine operation and reducing wear on other components.

Contribution to the Balance Shafts

In engines equipped with balance shafts, the crankshaft’s rotation is used to drive these shafts. Balance shafts counteract the vibrations produced by the engine, enhancing smoothness and reducing stress on engine components. The crankshaft’s consistent rotation ensures that the balance shafts operate effectively.

Integration with the Oil Pump

Many engines drive the oil pump off the front of the crankshaft. The crankshaft’s rotation powers the oil pump, which circulates lubricant throughout the engine. This integration ensures that the crankshaft and other moving parts receive a continuous supply of oil, crucial for their operation and longevity.

Conclusion

The Cummins 4900901 Engine Crankshaft is a vital component in heavy-duty truck engines, ensuring reliable performance and efficiency. Its robust construction, precise engineering, and compatibility with various Cummins engine models make it an essential part for maintaining the engine’s operation and longevity.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.