This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

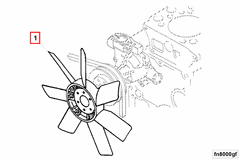

The Cummins 4900800 Engine Fan is a critical component in commercial trucks, designed to maintain the engine’s operating temperature within optimal ranges. This part is integral to the engine’s cooling system, preventing overheating and ensuring consistent performance 1.

Function and Operation

The 4900800 operates by drawing air through the radiator to cool the engine coolant. Driven by a belt connected to the engine, its speed is proportional to the engine’s RPM. The fan’s design enhances airflow management, crucial for dissipating heat and maintaining engine temperature, especially under heavy loads or high ambient temperatures 2.

Key Features

Constructed with durability and efficiency in mind, this Cummins part features a robust design capable of withstanding the rigors of commercial truck operation. The fan blades are made from high-quality materials that resist wear and corrosion, ensuring long-term reliability. Its design may include a shroud to direct airflow more effectively and reduce noise levels 3.

Benefits of Using Cummins 4900800 Engine Fan

Incorporating this part into a truck’s engine cooling system offers several advantages. It contributes to improved engine performance by maintaining optimal operating temperatures, enhancing fuel efficiency, and reducing the risk of overheating. The fan’s reliable operation supports the overall reliability of the engine, potentially reducing downtime and maintenance costs.

Installation Process

Installing the 4900800 requires careful attention to detail to ensure proper function and integration with the engine’s cooling system. The process involves securing the fan to the engine using the provided mounting hardware, ensuring the fan belt is correctly aligned and tensioned, and verifying that the fan operates freely without obstruction. It is important to follow the manufacturer’s guidelines to achieve the best results.

Maintenance Tips

To ensure the 4900800 operates efficiently over its lifespan, regular maintenance is recommended. This includes inspecting the fan and its components for signs of wear or damage, ensuring the fan belt is in good condition and properly tensioned, and cleaning the fan and radiator to remove any debris that could obstruct airflow. Adhering to these maintenance practices can help maintain optimal performance and extend the fan’s service life.

Common Issues and Troubleshooting

Users may encounter issues with the 4900800, such as unusual noises, reduced cooling efficiency, or mechanical failures. Troubleshooting these problems often involves inspecting the fan and its components for damage, ensuring the fan belt is correctly installed and tensioned, and checking for obstructions in the airflow path. Addressing these issues promptly can help maintain the engine’s cooling efficiency and prevent more serious problems.

Compatibility with Cummins Engines

This part is designed to fit seamlessly with a range of Cummins engines, including the A1400, A1700, A2000, and A2300 models. It is integral to the cooling system of these engines, ensuring optimal performance and longevity. The fan’s design allows for easy installation and compatibility with the specific dimensions and requirements of these engines.

Role in Various Engine Components

The 4900800 enhances the cooling process by increasing airflow over the radiator and other heat-generating components. It integrates with various engine components as follows:

- Radiator: Ensures the coolant is effectively cooled, preventing overheating.

- Cooling System: Compensates for insufficient natural airflow during low-speed or idling conditions.

- Thermostat: Signals the fan to turn on or off based on the coolant temperature, ensuring safe engine operation.

- Condenser: Aids in cooling the condenser in engines equipped with air conditioning.

- Heat Exchanger: Maintains a consistent flow of cool air, crucial for high-performance engines.

- Engine Bay Ventilation: Enhances ventilation within the engine bay, reducing the risk of heat-related damage.

- Intercooler (for Turbocharged Engines): Assists in cooling the compressed air before it enters the combustion chamber.

Conclusion

The Cummins 4900800 Engine Fan plays a vital role in maintaining engine health and performance by ensuring optimal cooling. Its robust design, compatibility with various Cummins engines, and integration with key engine components make it an essential part for commercial truck applications.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.