This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

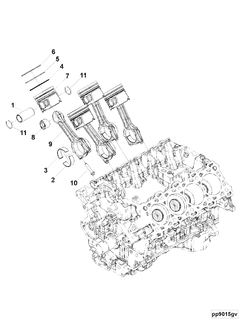

The Cummins 4359875 Engine Connecting Rod is a vital component in the operation of heavy-duty trucks. Its purpose is to facilitate the transfer of motion between the piston and the crankshaft, ensuring the efficient and reliable functioning of the engine. This component is integral to the overall performance and durability of the engine, making it a significant part of the truck’s powertrain system.

Basic Concepts of Engine Connecting Rods

An engine connecting rod serves as a link in the engine’s mechanical system. Its primary function is to convert the linear motion of the piston into rotational motion of the crankshaft. This conversion is fundamental to the engine’s operation, as it allows the energy produced by the combustion process to be harnessed and used to drive the vehicle. The connecting rod’s design and material composition play a role in the engine’s overall performance, influencing factors such as power output, fuel efficiency, and durability 1.

Purpose of the 4359875 Engine Connecting Rod

The 4359875 Engine Connecting Rod is designed to perform the task of transferring motion between the piston and the crankshaft in a truck engine. This transfer is achieved through the rod’s connection to the piston at one end and the crankshaft at the other. By facilitating this motion, the connecting rod contributes to the engine’s ability to generate power and drive the vehicle. Its design and construction are tailored to withstand the high stresses and loads encountered in heavy-duty applications.

Key Features

The 4359875 Engine Connecting Rod features a robust material composition and design elements that enhance its performance and durability. Constructed from high-strength materials, it is capable of withstanding the extreme conditions found in heavy-duty truck engines. Its design includes precision machining and heat treatment processes that improve its strength and resistance to wear. Additionally, the rod may incorporate features such as optimized weight distribution and advanced bearing surfaces to further enhance its performance.

Benefits

The 4359875 Engine Connecting Rod offers several benefits that contribute to improved engine efficiency, enhanced durability, and reliable performance under heavy-duty conditions. Its high-strength material composition and precision engineering allow it to operate efficiently even under the demanding conditions typical of heavy-duty truck applications. This results in better fuel efficiency, increased power output, and longer service life compared to standard connecting rods 2.

Installation and Compatibility

Proper installation of the 4359875 Engine Connecting Rod is crucial for ensuring optimal performance. Installation procedures should follow manufacturer guidelines to ensure correct alignment and secure fastening. Specific requirements may include torque specifications for fasteners and alignment checks to prevent premature wear or failure. Compatibility with the engine’s other components, such as the piston and crankshaft, is also important to ensure smooth operation and longevity.

Maintenance and Troubleshooting

Regular maintenance of the 4359875 Engine Connecting Rod is important for preserving its performance and longevity. This includes periodic inspection for signs of wear, damage, or misalignment. Lubrication recommendations should be followed to ensure proper functioning of the rod’s bearing surfaces. Troubleshooting common issues, such as unusual noises or vibrations, may involve checking for proper installation, alignment, and lubrication, as well as inspecting for signs of wear or damage.

Performance Enhancements

The 4359875 Engine Connecting Rod contributes to overall engine performance by enhancing power output, fuel efficiency, and reliability. Its high-strength material composition and precision engineering allow it to operate under the high stresses and loads encountered in heavy-duty applications. This results in improved engine efficiency, increased power output, and reliable performance, making it a valuable component for heavy-duty truck engines.

Common Failure Modes

Common failure modes associated with engine connecting rods include fatigue, wear, and breakage. Symptoms to watch for may include unusual noises, vibrations, or a decrease in engine performance. Potential causes of failure can include improper installation, misalignment, insufficient lubrication, or excessive stress and load. Recommended corrective actions may involve inspecting and replacing worn or damaged components, ensuring proper installation and alignment, and following lubrication recommendations.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and a reputation for producing high-quality engine components, Cummins is committed to delivering reliable and efficient power solutions for a variety of applications, including heavy-duty trucks. The company’s focus on quality, performance, and customer satisfaction has established it as a trusted name in the industry.

Engine Connecting Rod 4359875 by Cummins

The Engine Connecting Rod 4359875, manufactured by Cummins, is a critical component in various engine configurations. This part is designed to convert the linear motion of the piston into rotational motion, ensuring smooth and efficient engine operation.

Compatibility with ISV Engines

The Cummins Engine Connecting Rod 4359875 is specifically engineered to fit seamlessly with the ISV engines produced by Nissan. This compatibility ensures that the rod can handle the unique demands of these engines, providing durability and reliability under various operating conditions.

Integration with Cummins Engines

In Cummins engines, the 4359875 connecting rod is a vital part that interfaces directly with the crankshaft and piston. Its design allows for precise movement and minimal friction, contributing to the overall efficiency and longevity of the engine. Cummins engines, known for their robust performance, benefit from the high-quality construction and precision engineering of this connecting rod.

Grouping of Compatible Engines

The Cummins Engine Connecting Rod 4359875 is compatible with a range of engines, including but not limited to:

- Nissan ISV Engines

- Cummins Diesel Engines

- Cummins Natural Gas Engines

This part’s versatility makes it a valuable component for maintaining and repairing these engines, ensuring they continue to perform optimally.

Role of Part 4359875 Engine Connecting Rod in Engine Systems

The 4359875 Engine Connecting Rod is a fundamental component in the efficient operation of various engine systems. It serves as the vital link between the piston and the crankshaft, transmitting the force generated by the combustion process to rotate the crankshaft. This rotational motion is then converted into linear motion by the piston, which is essential for the engine’s operation.

In a long block kit, the 4359875 Engine Connecting Rod works in concert with the crankshaft, pistons, and cylinder block to form the core of the engine. It ensures that the force from each combustion event is effectively transferred, contributing to the engine’s overall performance and reliability.

When integrated into a short block kit, the connecting rod plays a similar role. However, in this configuration, it operates without the cylinder head and valve train components. This setup is often used for engine rebuilds or upgrades, where the connecting rod’s durability and precision are paramount to achieving the desired performance outcomes.

The connecting rod also interacts with the camshaft indirectly through the crankshaft. As the crankshaft rotates, driven by the connecting rods, it operates the camshaft via the timing chain or belt. This interaction is essential for the opening and closing of the valves, which control the intake of air-fuel mixture and the exhaust of combustion gases.

In high-performance engines, the 4359875 Engine Connecting Rod is often subjected to greater stresses due to increased combustion pressures and higher rotational speeds. Its design and material properties must be optimized to handle these conditions without failure, ensuring that the engine can deliver enhanced performance without compromising durability.

Furthermore, in engines equipped with direct fuel injectors, the precise timing and force transmission provided by the connecting rod are vital. The injectors rely on the engine’s consistent and smooth operation to deliver fuel at the optimal moment, maximizing combustion efficiency and power output.

Overall, the 4359875 Engine Connecting Rod is a key component in various engine systems, facilitating the transfer of force from the pistons to the crankshaft and contributing to the engine’s performance, reliability, and efficiency.

Conclusion

The Cummins 4359875 Engine Connecting Rod is a critical component in the operation of heavy-duty engines, ensuring efficient and reliable transfer of motion between the piston and crankshaft. Its robust design, high-strength materials, and precision engineering contribute to enhanced engine performance, durability, and fuel efficiency. Proper installation, maintenance, and understanding of common failure modes are essential for maximizing the benefits of this part in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.