4327239

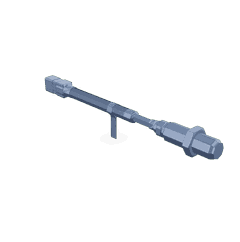

Engine Speed Sensor

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4327239 Engine Speed Sensor is a critical component designed to monitor and report the rotational speed of the engine in commercial trucks. This sensor is integral to the overall operation and performance of the vehicle, providing essential data that contributes to efficient engine management and optimal vehicle performance.

Basic Concepts of Engine Speed Sensors

An engine speed sensor, also known as a crankshaft position sensor, detects the rotational speed of an internal combustion engine’s crankshaft. By generating a signal that corresponds to this rotational speed, the sensor allows the engine management system to monitor and adjust engine operations in real-time. This includes synchronizing fuel injection, ignition timing, and other functions to ensure smooth and efficient engine performance 1.

Purpose of the Cummins 4327239 Engine Speed Sensor

The Cummins 4327239 Engine Speed Sensor is vital for the operation of a truck’s engine. It monitors the engine’s speed and sends this information to the engine control unit (ECU). The ECU uses this data to make precise adjustments to the engine’s operation, ensuring optimal performance under varying conditions. This sensor’s role in providing accurate and timely data is fundamental to the engine’s efficiency, reliability, and overall performance 2.

Key Features

The Cummins 4327239 Engine Speed Sensor is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and reliability in demanding environments. Technological advancements incorporated into this sensor enhance its performance, providing accurate and consistent readings even under extreme conditions. Its design is tailored to meet the rigorous demands of commercial truck engines, ensuring long-term reliability and performance 3.

Benefits of Using the Cummins 4327239 Engine Speed Sensor

Incorporating the Cummins 4327239 Engine Speed Sensor into truck engine systems offers several advantages. It contributes to improved engine performance by enabling the ECU to make precise adjustments based on real-time data. This results in enhanced fuel efficiency, as the engine operates more efficiently under various conditions. Additionally, the sensor’s diagnostic capabilities allow for early detection of potential issues, facilitating timely maintenance and reducing the risk of unexpected failures.

Installation and Compatibility

Proper installation of the Cummins 4327239 Engine Speed Sensor is crucial for its effective operation. It is designed to be compatible with a range of Cummins engine models, ensuring it can be integrated into various truck engine systems without modification. Following manufacturer guidelines during installation ensures the sensor operates correctly, providing accurate data to the ECU and contributing to the engine’s overall performance.

Troubleshooting and Maintenance

Common issues with the Cummins 4327239 Engine Speed Sensor may include inaccurate readings or sensor failure. Diagnostic procedures involve checking the sensor’s output signal and ensuring it aligns with the engine’s actual speed. Regular maintenance, such as cleaning the sensor and its connections, can help prevent issues and ensure optimal performance. Addressing problems promptly and performing routine maintenance contributes to the sensor’s longevity and reliability.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to innovation and quality in manufacturing engine components. The company’s dedication to advancing technology and improving product reliability is evident in its wide range of engine components, including the Cummins 4327239 Engine Speed Sensor.

Compatibility of Cummins Engine Speed Sensor 4327239

The Cummins Engine Speed Sensor part number 4327239 is designed to be compatible with a range of Cummins engines, ensuring reliable performance and accurate engine speed readings. Here is a detailed breakdown of its compatibility across various engine models:

QSK45 CM500 and QSK60 CM500 Engines

The 4327239 Engine Speed Sensor is engineered to fit seamlessly with the QSK45 CM500 and QSK60 CM500 engines. These engines are known for their robust design and efficiency, making them suitable for heavy-duty applications. The sensor’s placement and functionality are optimized to work with the specific architecture of these models, ensuring precise monitoring of engine speed.

QSK60 G CM2358 K110 and QSK60G Engines

For the QSK60 G CM2358 K110 and QSK60G engines, the 4327239 Engine Speed Sensor is also a perfect match. These engines are part of Cummins’ high-performance lineup, often used in demanding environments. The sensor’s design allows it to integrate smoothly with the engine’s control systems, providing critical data for optimal engine operation.

QST30 CM2350 T101 and QST30 CM552 Engines

The 4327239 Engine Speed Sensor is also compatible with the QST30 CM2350 T101 and QST30 CM552 engines. These engines are designed for versatility and reliability, making them ideal for a variety of applications. The sensor’s integration with these models ensures that engine speed is accurately monitored, contributing to the overall efficiency and performance of the engine.

By ensuring compatibility with these diverse engine models, the 4327239 Engine Speed Sensor from Cummins provides a reliable solution for maintaining engine performance across different applications.

Integration of Part 4327239 Engine Speed Sensor in Engine Systems

The Part 4327239 Engine Speed Sensor is an integral component in the orchestration of engine operations, ensuring precise monitoring and regulation of engine performance. Its role is multifaceted, interfacing with several key components to maintain optimal engine function.

Interaction with the Engine Control Module (ECM)

The Engine Speed Sensor is primarily responsible for generating a signal that reflects the rotational speed of the engine. This signal is transmitted to the Engine Control Module (ECM), which processes the data to make real-time adjustments to fuel injection, ignition timing, and other critical parameters. The accuracy of this signal is paramount for the ECM to execute its functions effectively.

Signal Generation and Transmission

As a Signal Generating Device, the Engine Speed Sensor captures the rotational speed of the engine and converts it into an electrical signal. This signal is then sent to the ECM. The integrity of this signal is essential for the ECM to make informed decisions regarding engine management.

Placement and Installation

The Position of the Engine Speed Sensor within the engine system is strategically chosen to ensure it can accurately measure engine speed. Typically, it is installed near the flywheel or crankshaft, where it can detect the rotation with high precision. Proper Product Installation is vital to ensure that the sensor is not only correctly aligned but also securely fastened to withstand the vibrations and temperatures within the engine compartment.

Role in the Engine Control Package

Within the broader Engine Control Package, the Engine Speed Sensor plays a supportive yet significant role. It provides essential data that, when combined with inputs from other sensors, allows the ECM to fine-tune engine performance. This holistic approach to engine management ensures that the engine operates efficiently under a variety of conditions.

Contribution to Overall Engine Performance

The data provided by the Engine Speed Sensor is a cornerstone in the engine’s Arrangement of components. It ensures that all moving parts are synchronized, reducing wear and tear and enhancing the longevity of the engine. Moreover, it contributes to the engine’s ability to meet emission standards by enabling precise control over combustion processes.

Conclusion

In summary, the Part 4327239 Engine Speed Sensor is a key player in the engine’s ecosystem, facilitating communication between the engine’s mechanical components and its electronic control system. Its accurate and reliable signal generation is fundamental to the engine’s performance, efficiency, and durability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.