4327233

Engine Speed Sensor

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4327233 Engine Speed Sensor is designed to monitor the rotational speed of the engine in commercial trucks. This sensor provides vital data to the engine control unit (ECU), which uses this information to manage various engine functions. Its role is significant in ensuring the engine operates efficiently and reliably under varying conditions.

Basic Concepts of Engine Speed Sensors

An Engine Speed Sensor, also known as a crankshaft position sensor, detects the rotational speed of the crankshaft. It operates by generating a signal each time a specific point on the crankshaft passes by the sensor. This signal is then sent to the ECU, which uses the data to control fuel injection timing, ignition timing, and other engine parameters 1. The sensor plays a role in the engine management system by providing real-time data that allows for precise control of engine operations.

Purpose of the Cummins 4327233 Engine Speed Sensor

The Cummins 4327233 Engine Speed Sensor is integral to the operation of a truck’s engine. It interacts with the ECU to provide accurate speed data, which the ECU uses to adjust engine parameters for optimal performance. This sensor ensures that the engine operates within its designed parameters, contributing to efficient fuel consumption and reduced emissions. Its interaction with other systems, such as the transmission and emissions control, further enhances overall vehicle performance 2.

Key Features

The Cummins 4327233 Engine Speed Sensor is characterized by its robust design and high-quality materials, which ensure durability and reliability in demanding environments. It features a precise sensing element that provides accurate speed readings, even under harsh operating conditions. The sensor’s design allows for easy installation and integration into the engine system, minimizing downtime during maintenance or replacement.

Benefits of Using the Cummins 4327233 Engine Speed Sensor

Utilizing the Cummins 4327233 Engine Speed Sensor offers several advantages. It contributes to improved engine performance by ensuring that the ECU has accurate speed data for making adjustments. This leads to better fuel efficiency, as the engine operates more efficiently with precise control over injection and ignition timing. Additionally, the sensor enhances reliability by providing consistent and accurate data, which is crucial for the long-term health of the engine 3.

Installation and Integration

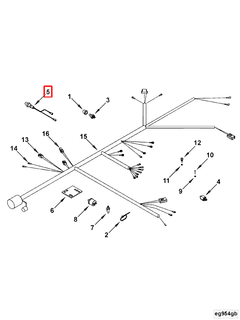

Proper installation of the Cummins 4327233 Engine Speed Sensor is crucial for its effective operation. It should be securely mounted in a location that allows it to accurately detect the crankshaft’s rotation. Integration into the engine system requires careful alignment with the ECU and other components to ensure seamless data transmission. Following manufacturer guidelines during installation helps prevent issues and ensures the sensor functions as intended.

Common Issues and Troubleshooting

Engine Speed Sensors can encounter issues such as signal interference, sensor misalignment, or electrical faults. Troubleshooting steps include checking the sensor’s alignment, ensuring secure electrical connections, and verifying the integrity of the signal path. Regular maintenance, such as cleaning the sensor and its surroundings, can prevent many common issues and ensure optimal performance.

Maintenance Practices

To prolong the lifespan and ensure consistent performance of the Cummins 4327233 Engine Speed Sensor, regular maintenance is recommended. This includes inspecting the sensor for signs of wear or damage, ensuring it remains securely mounted, and checking electrical connections for corrosion or looseness. Adhering to these practices helps maintain the sensor’s accuracy and reliability over time.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, known for its innovative products and commitment to customer satisfaction.

Engine Speed Sensor Compatibility with Cummins Engines

The Engine Speed Sensor part number 4327233, manufactured by Cummins, is compatible with a range of Cummins engines. This sensor is crucial for monitoring the rotational speed of the engine, providing essential data for the engine control unit (ECU) to manage performance and efficiency.

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- G5.9 CM558

- G8.3 CM558

- G855 CM558

- GTA8.3 CM558

- GTA855 CM558 (CM2358) G101

- M11 CELECT PLUS

- M11 MECHANICAL

- QSL9 G CM558

Grouping of Compatible Engines

The engines listed above can be grouped based on their model series and specifications:

-

G Series Engines:

- G5.9 CM558

- G8.3 CM558

- G855 CM558

- GTA8.3 CM558

- GTA855 CM558 (CM2358) G101

-

4B and 6B Series Engines:

- 4B3.9

- 6B5.9

- 6C8.3

-

M11 Series Engines:

- M11 CELECT PLUS

- M11 MECHANICAL

-

QSL9 Series Engine:

- QSL9 G CM558

This part is designed to fit seamlessly into these engines, ensuring accurate monitoring and control of engine speed across different models and specifications.

Role of Part 4327233 Engine Speed Sensor in Engine Systems

The Engine Speed Sensor, identified by part number 4327233, is integral to the operation of various engine systems. It works in conjunction with several components to ensure the engine operates efficiently and effectively.

Interaction with the Electronic Control Module (ECM)

The Engine Speed Sensor is directly connected to the Electronic Control Module (ECM) via a dedicated harness and wiring. This sensor generates a signal that the ECM uses to monitor the engine’s rotational speed. The ECM then processes this data to adjust fuel injection timing, ignition timing, and other parameters to optimize engine performance.

Signal Generation and Device Interface

The sensor is a signal-generating device that produces a consistent and reliable signal proportional to the engine’s speed. This signal is transmitted through the wiring harness to the ECM. The interface between the sensor and the ECM must be precise to ensure accurate data transmission. Any discrepancies in this interface can lead to incorrect readings and subsequent engine performance issues.

Engine Control and Monitoring Systems

Within the engine control system, the Engine Speed Sensor plays a significant role. It provides real-time data that the ECM uses to make instantaneous adjustments. This is particularly important in systems that require step time control, where quick responses are necessary to maintain engine stability and efficiency.

Integration with Engine Monitoring

The Engine Speed Sensor is also a key component in the engine monitoring system. It allows for continuous surveillance of the engine’s operational status. By providing accurate speed data, it enables the monitoring system to detect anomalies, predict potential failures, and ensure that the engine operates within safe parameters.

Conclusion

In summary, the Engine Speed Sensor (part 4327233) is a vital component that ensures the seamless operation of the engine control and monitoring systems. Its accurate signal generation and reliable interface with the ECM are essential for maintaining engine performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.