This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3943446 Engine Piston is a critical component designed for commercial trucks, ensuring efficient operation under demanding conditions. Its robust design and construction are tailored to meet the rigorous requirements of heavy-duty applications, providing reliable performance and durability 3.

Basic Concepts of Engine Pistons

An engine piston is a cylindrical component that moves within the engine’s cylinders, converting the energy from fuel combustion into mechanical work. This movement is synchronized with the crankshaft’s rotation, facilitating the engine’s four-stroke cycle: intake, compression, power, and exhaust 1.

Role of the 3943446 Engine Piston in Truck Operation

This Cummins part is integral to the truck engine’s operation, interacting with components like the crankshaft, connecting rod, and cylinder walls to ensure smooth performance. Its design allows it to withstand high pressures and temperatures, contributing to the engine’s efficiency and power output 3.

Key Features of the 3943446 Engine Piston

The 3943446 features a forged aluminum construction for strength and lightweight properties. It includes precision-machined surfaces for a tight fit within the cylinder, minimizing friction and wear. The piston’s unique skirt design enhances stability and reduces the risk of piston slap 3.

Benefits of Using the 3943446 Engine Piston

Utilizing this part offers advantages such as improved engine efficiency, enhanced durability, and increased reliability. Its design contributes to reduced fuel consumption and emissions, aligning with environmental standards. The piston’s construction ensures it can withstand heavy-duty use, providing long-term performance and value 3.

Troubleshooting and Maintenance Suggestions

Regular inspections and maintenance are recommended to maintain the performance of this part. This includes checking for wear or damage, ensuring proper lubrication, and addressing issues promptly to prevent further damage. Following the manufacturer’s guidelines for maintenance intervals and procedures can help ensure the piston’s longevity and optimal operation 3.

Manufacturing and Quality Assurance

The manufacturing process of this part involves precision engineering and stringent quality control measures. Cummins employs advanced techniques and materials to ensure the piston meets high standards of performance and reliability. Quality assurance tests are conducted throughout production to verify the piston’s integrity and functionality 3.

Historical Development of Engine Pistons

The evolution of engine pistons has seen significant advancements in materials, design, and manufacturing techniques. Early pistons were made from cast iron, which offered durability but was heavy. The introduction of aluminum and forged materials provided a balance of strength, lightweight properties, and thermal efficiency, directly influencing the design and performance of modern pistons like the 3943446 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. Established in 1919, Cummins is known for its innovative products, quality, and customer service in the commercial truck industry 3.

Compatibility of Engine Piston 3943446

The Cummins Engine Piston part number 3943446 is designed for specific engine models, ensuring optimal performance and longevity.

ISC CM554

The ISC CM554 engine is robust and reliable for heavy-duty applications. The 3943446 piston is engineered to meet the demands of this engine model, ensuring efficient combustion and reduced wear.

QSC8.3 CM554

The QSC8.3 CM554 engine benefits from the precision engineering of the 3943446 piston. This engine model is known for its power and efficiency, and the piston is crafted to enhance these attributes. The fitment is precise, ensuring smooth operation within the engine’s cylinder.

Grouping of Engines

Both the ISC CM554 and QSC8.3 CM554 engines share a common platform, allowing the 3943446 piston to be used interchangeably. This commonality simplifies maintenance and repair processes, reducing inventory needs and ensuring consistent performance.

Role of Part 3943446 Engine Piston in Engine Systems

This part is a fundamental component that interacts with several other engine parts to ensure efficient operation.

Interaction with Cylinder Block

The Engine Piston moves within the cylinder block, facilitating the intake, compression, combustion, and exhaust processes. The precise fit and movement within the cylinder block ensure minimal friction and maximum efficiency.

Integration with Cylinder Kit

When a cylinder kit is installed, it often includes new cylinder sleeves or liners. The Engine Piston must be compatible with these new components to maintain proper clearances and ensure smooth operation.

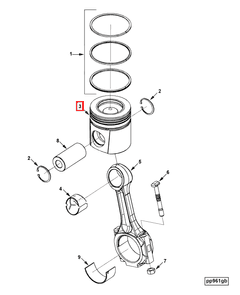

Role in Engine Piston Kit

Part 3943446 is often included in an Engine Piston Kit, which may consist of pistons, rings, pins, and clips. The coordination between these components is essential for the piston’s function.

Enhancement with Performance Parts

Incorporating performance parts into an engine build often involves upgrading the Engine Piston. Part 3943446 may be designed to withstand higher temperatures, pressures, and stresses. Its interaction with other performance components allows the engine to produce more power and operate more efficiently.

Function within Short Block

A short block typically includes the cylinder block, crankshaft, connecting rods, and Engine Piston. Part 3943446 plays a significant role in this assembly by converting the energy from combustion into mechanical motion. Its interaction with the crankshaft via the connecting rod is essential for transmitting power to the rest of the engine system.

Conclusion

The Cummins 3943446 Engine Piston is integral to the functioning of these engine components, ensuring that the engine operates smoothly and efficiently. Its robust design, precision engineering, and compatibility with various engine models make it a reliable choice for heavy-duty applications.

-

Ben Watson, Mobile Equipment Hydraulics A Systems and Troubleshooting Approach (Cengage Learning, 2011).

↩ -

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition (Butterworth-Heinemann, 2007).

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.