This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

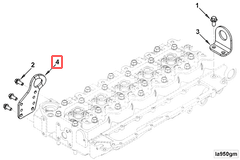

The Cummins 3943216 Engine Lifting Bracket is a specialized component designed for the maintenance and repair of heavy-duty trucks. This bracket is integral to the process of safely and efficiently removing and reinstalling engines, ensuring that maintenance tasks are performed with precision and care.

Purpose and Function

The Cummins 3943216 Engine Lifting Bracket plays a significant role in the operation of heavy-duty trucks by facilitating the engine removal and installation processes. It provides a secure point of attachment for lifting equipment, allowing mechanics to handle the engine with greater ease and safety. This bracket ensures that the engine is supported correctly during these operations, reducing the risk of damage to both the engine and the surrounding components 1.

Key Features

The design and construction of the Cummins 3943216 Engine Lifting Bracket are tailored to meet the demanding requirements of heavy-duty truck maintenance. It is crafted from high-strength materials, ensuring durability and reliability under heavy loads. The bracket features a robust structure that can withstand the stresses associated with engine lifting. Additionally, its design includes specific mounting points and alignment features that enhance its functionality and ease of use 2.

Benefits

Utilizing the Cummins 3943216 Engine Lifting Bracket offers several advantages. It improves safety during engine handling by providing a stable and secure attachment point for lifting equipment. This reduces the likelihood of accidents and injuries. Additionally, the bracket helps to streamline the engine removal and installation processes, potentially reducing repair times. Its durable construction ensures long-term reliability, making it a valuable tool for any heavy-duty truck maintenance facility 3.

Installation Process

Proper installation of the Cummins 3943216 Engine Lifting Bracket is crucial for its effective use. The process involves several steps:

- Ensure the truck is securely supported on a level surface.

- Locate the designated mounting points on the engine and chassis.

- Align the bracket with these points and use the appropriate fasteners to secure it in place.

- Verify that the bracket is properly aligned and tightly fastened before proceeding with engine lifting operations.

Troubleshooting Common Issues

Mechanics may encounter several issues when using the Cummins 3943216 Engine Lifting Bracket, including misalignment, wear and tear, and compatibility problems. To address these issues:

- Check for proper alignment during installation to prevent misalignment.

- Inspect the bracket regularly for signs of wear and replace it if necessary to maintain safety and functionality.

- Ensure the bracket is compatible with the specific engine and truck model to avoid fitting issues.

Maintenance Tips

Regular maintenance of the Cummins 3943216 Engine Lifting Bracket is essential for its longevity and optimal performance. This includes:

- Conducting routine inspections to check for damage or wear.

- Cleaning the bracket to remove any debris or contaminants that could affect its performance.

- Ensuring all fasteners are tight and secure to maintain structural integrity.

Safety Considerations

When using the Cummins 3943216 Engine Lifting Bracket, it is important to observe several safety protocols:

- Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards.

- Use proper lifting techniques to avoid strain and injury.

- Ensure the work environment is clear of obstacles and that the lifting equipment is in good working condition.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the production of diesel engines and related components. The company’s commitment to innovation and quality has made it a preferred choice for heavy-duty truck manufacturers and maintenance professionals worldwide.

Cummins Engine Lifting Bracket 3943216 Compatibility

The Cummins Engine Lifting Bracket part number 3943216 is a critical component designed to facilitate the safe and efficient lifting of specific Cummins engines. This part is engineered to ensure secure mounting and handling during maintenance, installation, or removal procedures.

ISB CM550 Engines

The Cummins ISB CM550 engine is a robust and reliable power unit often utilized in various industrial and commercial applications. The Engine Lifting Bracket 3943216 is specifically designed to fit seamlessly with the ISB CM550 engine, providing the necessary support and stability required for safe lifting operations. This bracket ensures that the engine is securely fastened, minimizing the risk of damage during transport or maintenance.

Other Cummins Engines

While the primary focus of the Cummins Engine Lifting Bracket 3943216 is on the ISB CM550 engine, it is also compatible with other Cummins engine models. This versatility makes it a valuable tool for technicians and maintenance personnel who work with multiple engine types. The bracket’s design allows it to be adapted to fit various engine configurations, ensuring a secure fit and reliable performance across different engine models.

By using the Cummins Engine Lifting Bracket 3943216, users can enhance the safety and efficiency of their engine handling processes, reducing the likelihood of accidents and equipment damage. This part is a testament to Cummins’ commitment to providing high-quality, reliable components that meet the demands of modern industrial applications.

Role of Part 3943216 Engine Lifting Bracket in Engine Systems

When integrating part 3943216 Engine Lifting Bracket into engine systems, it significantly enhances the arrangement and lifting processes. This component is designed to provide a secure attachment point for lifting equipment, ensuring that the engine can be safely and efficiently maneuvered during maintenance, repair, or installation procedures.

Arrangement

The Engine Lifting Bracket plays a key role in the arrangement of engine components during disassembly and reassembly. By offering a stable and reliable point of connection, it allows mechanics to precisely position the engine within the vehicle’s chassis. This is particularly important in ensuring that all connecting components, such as drive belts, hoses, and electrical connections, are correctly aligned and tensioned. Proper arrangement facilitated by the lifting bracket reduces the risk of misalignment, which can lead to operational issues or damage during engine startup.

Lifting

During the lifting process, the Engine Lifting Bracket ensures that the engine is evenly supported, minimizing the risk of structural damage. This is essential when removing the engine from the vehicle for overhaul or replacement. The bracket distributes the lifting force across a broader area of the engine, preventing stress concentrations that could cause cracks or deformations in the engine block or other critical components. Additionally, it allows for safer handling by providing a clear and accessible point for lifting straps or chains, reducing the likelihood of accidents due to improper lifting techniques.

Conclusion

The Cummins 3943216 Engine Lifting Bracket is a vital component in the maintenance and repair of heavy-duty trucks. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of safety and efficiency make it an indispensable tool for mechanics and maintenance professionals. Proper installation, regular maintenance, and adherence to safety protocols ensure that this Cummins part continues to provide reliable service, contributing to the overall efficiency and safety of engine handling processes.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.