Introduction

The Cummins 3924432 Engine Speed Sensor is a component designed to monitor and report the rotational speed of the engine’s crankshaft. This sensor plays a role in the operation of commercial trucks by providing data to the engine control unit (ECU), which uses this information to manage various engine functions efficiently.

Basic Concepts of Engine Speed Sensors

An Engine Speed Sensor is a device that detects the rotational speed of an engine’s crankshaft or flywheel. It operates using either magnetic or optical technology to generate a signal that corresponds to the engine’s speed. This signal is then transmitted to the ECU, which uses the data to adjust fuel injection timing, ignition timing, and other parameters to optimize engine performance and efficiency 1.

Purpose of the Cummins 3924432 Engine Speed Sensor

The Cummins 3924432 Engine Speed Sensor is integral to the operation of a truck’s engine. It provides the ECU with precise data on engine speed, allowing for adjustments that enhance performance and efficiency. This sensor ensures that the engine operates within optimal parameters, contributing to smooth operation and reduced emissions.

Key Features

The Cummins 3924432 Engine Speed Sensor is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and reliability. Its precise engineering allows for accurate speed detection, which is vital for the ECU to make informed adjustments. Additionally, the sensor is designed to withstand the harsh environments typical of commercial truck operations 2.

Benefits of Using the Cummins 3924432 Engine Speed Sensor

Incorporating the Cummins 3924432 Engine Speed Sensor into a truck’s engine system offers several advantages. These include improved fuel efficiency through optimized fuel injection timing, enhanced engine performance due to precise ignition timing, and increased reliability from accurate engine speed data. The sensor contributes to overall engine health by ensuring that all components operate within their designed parameters 3.

Installation and Compatibility

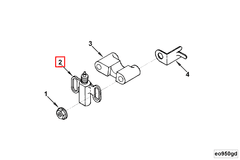

Proper installation of the Cummins 3924432 Engine Speed Sensor is crucial for its effective operation. It is designed to be compatible with various Cummins engine models, ensuring a seamless integration into the engine management system. Specific installation guidelines should be followed to ensure the sensor is correctly positioned and securely attached.

Troubleshooting and Maintenance

Regular maintenance of the Cummins 3924432 Engine Speed Sensor is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage and cleaning to remove any debris that may affect its operation. Troubleshooting common issues may involve checking the sensor’s connections, ensuring it is properly aligned, and verifying that the signal output is within expected parameters.

Common Failure Modes

The Cummins 3924432 Engine Speed Sensor, like any electronic component, can experience failures. Typical failure modes include signal degradation due to wear, electrical issues, or physical damage. Symptoms of a faulty sensor may include erratic engine performance, difficulty starting the engine, or illumination of the check engine light. Diagnosing a faulty sensor involves checking the signal output and comparing it to known good values. Replacement should be performed according to manufacturer guidelines to ensure proper function.

Impact on Engine Performance

The Cummins 3924432 Engine Speed Sensor plays a role in the engine’s performance by providing accurate speed data to the ECU. This data is used to adjust fuel injection and ignition timing, contributing to efficient combustion and emissions control. Accurate speed data is also important for maintaining overall engine health, as it allows the ECU to make real-time adjustments to engine parameters.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to advancing technology and improving product reliability is evident in its engine components, including the Cummins 3924432 Engine Speed Sensor.

Cummins Engine Speed Sensor 3924432 Compatibility

The Cummins Engine Speed Sensor part number 3924432 is designed to fit seamlessly with several engine models, ensuring precise engine performance monitoring and control. This sensor is integral to the engine’s electronic control unit (ECU), providing real-time data on engine speed which is crucial for various engine functions.

6B5.9 Engine Series

The 6B5.9 engine series, known for its robust performance and reliability, is one of the key beneficiaries of the 3924432 Engine Speed Sensor. This sensor is specifically engineered to integrate with the 6B5.9 engine’s architecture, ensuring that the ECU receives accurate speed data. This compatibility is vital for maintaining optimal engine performance, fuel efficiency, and overall reliability.

The 3924432 sensor is designed to withstand the demanding conditions of the 6B5.9 engine, including high temperatures and vibrations. Its robust construction ensures longevity and consistent performance, making it a preferred choice for this engine series.

Other Cummins Engines

While the 6B5.9 engine series is a primary focus, the 3924432 Engine Speed Sensor is also compatible with other Cummins engines. This versatility is due to the sensor’s universal design, which adheres to Cummins’ stringent quality standards. The sensor’s ability to interface with various engine models underscores its importance in the broader Cummins engine ecosystem.

By ensuring precise engine speed data, the 3924432 sensor plays a role in the efficient operation of these engines. Its compatibility with multiple engine models highlights Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and longevity.

Understanding the Role of Part 3924432 Engine Speed Sensor in Engine Systems

The engine speed sensor, specifically part 3924432, is an integral component within the engine system, providing essential data that contributes to the overall performance and efficiency of the engine. This sensor is designed to monitor the rotational speed of the engine’s crankshaft, which is a fundamental parameter for the engine control unit (ECU) to make precise adjustments to fuel injection, ignition timing, and other critical engine functions.

Integration with the Engine Control Unit (ECU)

The engine speed sensor communicates directly with the ECU, transmitting real-time data on the engine’s rotational speed. This information allows the ECU to make instantaneous adjustments to ensure optimal engine performance. For instance, if the sensor detects a decrease in engine speed, the ECU can increase fuel injection or adjust the ignition timing to maintain engine stability and power output.

Interaction with the Fuel Injection System

In fuel-injected engines, the engine speed sensor plays a role in regulating the fuel injection process. By providing accurate speed data, the sensor ensures that the fuel injection system delivers the correct amount of fuel at the right time, enhancing fuel efficiency and reducing emissions. This precise control over fuel delivery is essential for maintaining the engine’s performance across various operating conditions.

Coordination with the Ignition System

The engine speed sensor also works in tandem with the ignition system. It provides the necessary speed information for the ECU to determine the optimal ignition timing. Proper ignition timing is vital for maximizing engine power, improving fuel economy, and reducing emissions. The sensor ensures that the spark plugs fire at the precise moment, leading to more efficient combustion and smoother engine operation.

Contribution to Transmission Systems

In vehicles equipped with automatic transmissions, the engine speed sensor aids in smooth gear shifts. By monitoring the engine’s RPM, the sensor helps the transmission control unit (TCU) decide the appropriate time to shift gears, ensuring a seamless driving experience. This coordination between the engine and transmission systems is essential for vehicle performance and drivability.

Enhancement of Emission Control Systems

Modern engines are equipped with various emission control systems, such as catalytic converters and exhaust gas recirculation (EGR) systems. The engine speed sensor provides the ECU with the data needed to optimize these systems. For example, by knowing the engine speed, the ECU can adjust the EGR valve to recirculate the right amount of exhaust gases, reducing harmful emissions while maintaining engine efficiency.

Support for On-Board Diagnostics (OBD)

The engine speed sensor is also a key component in the vehicle’s on-board diagnostics (OBD) system. It helps monitor the engine’s performance and detect any anomalies or malfunctions. If the sensor detects irregular engine speed patterns, it can trigger a diagnostic trouble code (DTC), alerting the driver to potential issues that need attention. This proactive monitoring helps in early detection and prevention of more significant engine problems.

Conclusion

The Cummins 3924432 Engine Speed Sensor is a vital component that ensures the engine operates efficiently and effectively. Its role in providing accurate speed data to the ECU and other systems underscores its importance in modern engine management.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.