This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

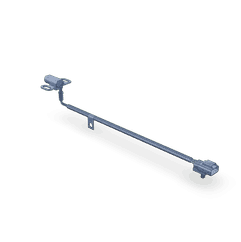

The Cummins 3923129 Engine Speed Sensor is designed to monitor the rotational speed of the engine in commercial trucks. This sensor provides real-time data on engine speed to the engine control unit (ECU), contributing to the overall performance and management of the vehicle 2.

Basic Concepts of Engine Speed Sensors

An Engine Speed Sensor detects the rotational speed of an engine using magnetic or optical technologies. It measures the speed of the crankshaft or flywheel, providing crucial information to the engine management system. This data allows the ECU to adjust fuel injection, ignition timing, and other parameters to optimize engine performance and efficiency 3.

Purpose of the Cummins 3923129 Engine Speed Sensor

The Cummins 3923129 Engine Speed Sensor monitors the rotational speed of the engine and transmits this data to the ECU. This enables the ECU to make precise adjustments to various engine parameters, ensuring optimal performance, fuel efficiency, and emissions control. The sensor’s accurate measurement of engine speed is vital for the ECU to function correctly and maintain engine performance under varying conditions 4.

Key Features

The Cummins 3923129 Engine Speed Sensor is characterized by its robust design and construction. It is built using high-quality materials to ensure durability and reliability in demanding environments. The sensor includes features that enhance its performance, such as precise measurement capabilities and resistance to environmental factors that could affect its operation 1.

Benefits of Using the Cummins 3923129 Engine Speed Sensor

Incorporating the Cummins 3923129 Engine Speed Sensor into a truck’s engine system offers several advantages. It contributes to improved engine performance by enabling the ECU to make real-time adjustments based on accurate speed data. This can lead to enhanced fuel efficiency, as the engine operates more efficiently under the ECU’s management. Additionally, the sensor’s reliable operation under various conditions ensures consistent performance and reduces the likelihood of engine-related issues 2.

Installation and Integration

Proper installation and integration of the Cummins 3923129 Engine Speed Sensor are crucial for its effective operation. It is important to ensure compatibility with the specific engine model and to follow guidelines for correct placement and wiring. This ensures that the sensor can accurately measure engine speed and transmit this data to the ECU without interference or signal loss 3.

Troubleshooting and Maintenance

To maintain the Cummins 3923129 Engine Speed Sensor’s performance, it is important to be aware of common issues and their solutions. Diagnostic procedures can help identify problems such as incorrect readings or sensor failure. Regular maintenance practices, including checking for damage, ensuring secure connections, and cleaning the sensor, can help ensure its longevity and reliable operation 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles, demonstrating Cummins’ dedication to customer satisfaction and technological advancement 1.

Cummins Engine Speed Sensor 3923129 Compatibility

The Cummins Engine Speed Sensor part number 3923129 is designed to monitor engine performance across various engine models. This sensor fits seamlessly within the engine architecture of several Cummins engines, ensuring accurate data transmission for optimal engine operation.

Compatible Engines

- 6B5.9 Series

- The 3923129 sensor is specifically engineered to integrate with the 6B5.9 engines. This engine series is known for its robust performance and reliability, making it a popular choice in various applications. The sensor’s placement and design ensure it can withstand the operational conditions of these engines, providing consistent and reliable data.

Installation and Functionality

The installation of the 3923129 sensor in Cummins engines is straightforward, designed to fit into the engine’s architecture without requiring extensive modifications. This ease of installation is crucial for maintaining the engine’s efficiency and performance. The sensor’s role is to monitor the rotational speed of the engine, sending vital data to the engine control unit (ECU). This information is essential for the ECU to manage fuel injection, ignition timing, and other critical engine functions.

Importance of the Sensor

The Engine Speed Sensor 3923129 is integral to the engine’s overall performance and efficiency. By accurately measuring the engine’s speed, it enables the ECU to make real-time adjustments, ensuring the engine operates at peak efficiency. This sensor’s reliability and precision are paramount, as any inaccuracies can lead to suboptimal engine performance, increased fuel consumption, and potential engine damage over time.

Maintenance and Replacement

Regular maintenance of the 3923129 sensor is recommended to ensure its longevity and performance. This includes periodic checks for any signs of wear or damage and ensuring the sensor is securely mounted within the engine. Replacement of the sensor should be done with a part that meets Cummins’ specifications to maintain the engine’s integrity and performance.

Role of Part 3923129 Engine Speed Sensor in Engine Systems

The part 3923129 Engine Speed Sensor is integral to the operation of various engine systems, ensuring precise monitoring and control of engine performance.

Integration with the Engine Control Unit (ECU)

The Engine Speed Sensor (ESS) communicates directly with the Engine Control Unit (ECU). It provides real-time data on the rotational speed of the engine’s crankshaft. This information allows the ECU to make necessary adjustments to fuel injection timing, ignition timing, and other critical parameters to optimize engine performance and efficiency 2.

Interaction with the Transmission Control System

In vehicles equipped with automatic transmissions, the ESS plays a significant role. It sends speed data to the Transmission Control Module (TCM), which uses this information to determine the appropriate gear changes. This ensures smooth and efficient transmission operation, enhancing both performance and fuel economy 3.

Contribution to the Anti-lock Braking System (ABS)

The ESS also interfaces with the Anti-lock Braking System (ABS). By providing accurate engine speed data, it helps the ABS module modulate brake pressure during emergency stops, preventing wheel lock-up and maintaining vehicle stability 4.

Role in the Traction Control System (TCS)

In vehicles with Traction Control Systems, the ESS is vital. It supplies engine speed information to the TCS module, which uses this data to detect wheel spin. When wheel spin is detected, the TCS can reduce engine power or apply brakes to the spinning wheel, thereby maintaining traction and control 1.

Influence on the Cruise Control System

For vehicles equipped with cruise control, the ESS ensures that the system maintains a consistent speed. By continuously monitoring engine speed, the cruise control module can make minor adjustments to the throttle position, keeping the vehicle at the desired speed despite changes in road grade or wind resistance 2.

Impact on the On-Board Diagnostics (OBD) System

The ESS is also a key component in the On-Board Diagnostics (OBD) system. It provides essential data that the OBD uses to monitor the overall health of the engine. Any irregularities in engine speed can trigger diagnostic trouble codes, alerting the driver to potential issues that need attention 3.

Synergy with the Ignition System

Finally, the ESS works in tandem with the ignition system. By providing precise engine speed data, it ensures that the ignition timing is accurately set, which is essential for efficient combustion and reduced emissions 4.

Conclusion

The part 3923129 Engine Speed Sensor is a multifaceted component that enhances the functionality and performance of various engine systems. Its accurate and timely data transmission is essential for the smooth operation of modern vehicles.

-

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ ↩ ↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ ↩ ↩ ↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ ↩ ↩ ↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.