3919585

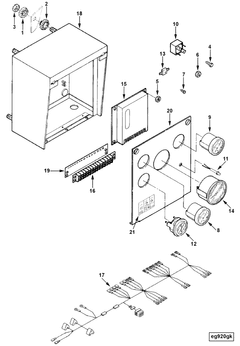

Engine Instrumentation Panel

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3919585 Engine Instrumentation Panel is a sophisticated component designed to monitor and display various engine performance metrics in commercial trucks. Its role is significant in ensuring the efficient operation and maintenance of the vehicle. By providing real-time data and alerts, it aids in the proactive management of engine health and performance 1.

Purpose and Functionality

This Cummins part serves to monitor and display critical engine performance metrics such as temperature, pressure, and fuel efficiency. It plays a role in the engine’s operation by providing drivers and maintenance personnel with vital information that aids in the efficient operation and maintenance of the truck. This panel helps in identifying potential issues before they escalate into major problems, thereby contributing to the longevity and reliability of the engine 2.

Key Features

The primary features of the 3919585 include a high-resolution digital display, multiple connectivity options for integration with other vehicle systems, and compatibility with a range of truck models and engine types. It is designed to offer clear and concise readouts of engine metrics, along with alert systems for abnormal conditions.

Benefits

This part offers several advantages. It enhances engine performance monitoring by providing real-time data, improves driver awareness of engine conditions, and facilitates timely maintenance by alerting operators to potential issues. This leads to more efficient operation, reduced downtime, and extended engine life 3.

Installation and Integration

Proper installation and integration of this part within the truck’s existing systems are crucial for its effective operation. It is designed to be compatible with various truck models and engine types, ensuring seamless integration. Guidelines for installation should be followed to ensure optimal performance and compatibility.

Troubleshooting and Maintenance

Common issues that may arise with this part include display malfunctions and connectivity issues. Troubleshooting steps may involve checking connections, updating software, or recalibrating the panel. Regular maintenance, such as cleaning the display and ensuring all connections are secure, can help ensure the longevity and optimal performance of the panel.

User Interface and Operation

The user interface of the 3919585 is designed for ease of use, featuring clear display readouts, intuitive alert systems, and straightforward control options. Drivers can quickly access critical engine data and respond to alerts, enhancing their ability to manage engine performance effectively.

Technological Advancements

This part incorporates several technological features, including digital displays for clear readouts, wireless connectivity for integration with other systems, and advanced diagnostic capabilities. These features contribute to its effectiveness in monitoring and managing engine performance.

Safety and Compliance

The 3919585 contributes to overall vehicle safety and compliance with industry regulations through its alert systems and diagnostic features. By providing real-time data and alerts for abnormal conditions, it helps ensure that the engine operates within safe parameters, enhancing both vehicle safety and regulatory compliance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality in engine and component manufacturing, Cummins plays a significant role in the commercial truck industry. The company’s commitment to advancing technology and improving engine performance is evident in products like the 3919585.

Understanding the Integration of 3919585 with Engine Systems

The Engine Instrumentation Panel (Part 3919585) serves as a central hub for monitoring and displaying various engine parameters. This panel is intricately connected to several key components within the engine system to ensure optimal performance and safety.

Connection to Engine Sensors

The panel interfaces directly with a multitude of sensors distributed throughout the engine. These sensors measure parameters such as engine temperature, oil pressure, fuel levels, and RPMs. The data collected by these sensors is transmitted to the instrumentation panel, where it is processed and displayed in an easily readable format for the operator.

Integration with the Engine Control Unit (ECU)

A significant aspect of the panel’s functionality is its communication with the Engine Control Unit (ECU). The ECU relies on the instrumentation panel to receive real-time data, which it uses to make adjustments to the engine’s operation. This bidirectional flow of information allows for precise control over engine performance and ensures that any deviations from normal operating conditions are promptly addressed.

Role in Fuel Management System

The panel also plays a part in the fuel management system by displaying fuel consumption rates and remaining fuel levels. This information is vital for efficient fuel usage and helps in planning refueling stops, especially in aviation or marine applications where fuel capacity and consumption are closely monitored.

Interaction with the Ignition System

In conjunction with the ignition system, the panel provides insights into the engine’s ignition timing and spark plug performance. This data is essential for maintaining the engine’s efficiency and longevity, as improper ignition can lead to increased wear and reduced performance.

Monitoring the Lubrication System

The lubrication system’s health is indicated through oil pressure and temperature readings displayed on the panel. Consistent monitoring of these parameters ensures that the engine remains properly lubricated, which is fundamental to preventing overheating and mechanical failure.

Contribution to Emissions Control

Modern engine instrumentation panels are also equipped to monitor emissions-related data. This includes exhaust gas temperatures and emissions levels, which are critical for compliance with environmental regulations and for maintaining the engine’s ecological footprint.

Support for Maintenance and Diagnostics

Finally, the panel aids in maintenance and diagnostics by providing alerts and warnings for any anomalies detected within the engine system. This proactive approach to maintenance helps in identifying potential issues before they escalate into more significant problems, thereby enhancing the engine’s reliability and lifespan.

Conclusion

The Cummins 3919585 Engine Instrumentation Panel is a vital component in the management and maintenance of commercial truck engines. Its sophisticated design and integration with various engine systems ensure that drivers and maintenance personnel have access to critical engine data in real-time. This not only enhances engine performance and longevity but also contributes to overall vehicle safety and regulatory compliance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.