3913112

Engine Heater Cable

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

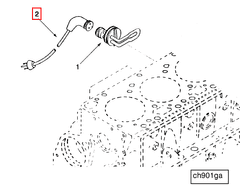

The Cummins 3913112 Engine Heater Cable is a component designed to enhance the operation of heavy-duty trucks, particularly in cold weather conditions. Its purpose is to facilitate easier engine starts by pre-heating the engine, which can be particularly beneficial in environments where temperatures drop significantly. This component plays a role in improving the overall efficiency and reliability of truck operations in such conditions 1.

Basic Concepts of Engine Heater Cables

An engine heater cable is a device used in the pre-heating process of diesel engines. It functions by providing electrical resistance heating to specific engine components, typically the coolant, to raise the engine temperature before starting. This process reduces the strain on the engine during start-up, which can be particularly demanding in cold weather. The role of the heater cable is to ensure that the engine reaches an optimal operating temperature more quickly, thereby enhancing performance and reducing wear on engine components 2.

Purpose of the 3913112 Engine Heater Cable

The 3913112 Engine Heater Cable is designed to facilitate easier engine starts in cold weather conditions. By pre-heating the engine, it reduces the viscosity of the oil and the density of the fuel, making it easier for the engine to turn over. This not only improves the starting process but also helps in achieving quicker warm-up times, which is crucial for maintaining engine efficiency and reducing emissions 3.

Key Features

The 3913112 Engine Heater Cable boasts several key features that enhance its functionality and ease of use. Its durable construction ensures longevity and reliability under various operating conditions. It is specifically designed for compatibility with Cummins engines, ensuring seamless integration and optimal performance. Additionally, the cable is engineered for ease of installation, allowing for straightforward setup without the need for complex modifications 4.

Benefits of Using the 3913112 Engine Heater Cable

Utilizing the 3913112 Engine Heater Cable offers several advantages. It contributes to improved engine performance in cold weather by ensuring that the engine reaches its optimal operating temperature more quickly. This can lead to reduced wear and tear on engine components, as the engine is not subjected to the stress of cold starts. Furthermore, pre-heating the engine can enhance fuel efficiency by allowing the engine to operate more effectively from the moment it starts 5.

Installation Process

Installing the 3913112 Engine Heater Cable involves several steps to ensure proper setup. Begin by identifying the correct location for the cable within the engine compartment. Use the provided mounting brackets to secure the cable in place. Connect the electrical terminals according to the manufacturer’s instructions, ensuring a secure and proper connection. Finally, test the installation to confirm that the cable is functioning correctly. It is important to follow all safety precautions during installation, including disconnecting the battery to prevent electrical shocks 6.

Troubleshooting Common Issues

Common issues with the 3913112 Engine Heater Cable may include electrical faults or heating element malfunctions. To troubleshoot these problems, first, check the electrical connections to ensure they are secure and free from corrosion. If the cable does not heat up, verify that the power source is functioning correctly and that there are no breaks in the cable. Consulting the manufacturer’s troubleshooting guide can provide additional steps and solutions for resolving these issues 7.

Maintenance Tips

To ensure the optimal performance and longevity of the 3913112 Engine Heater Cable, regular maintenance is recommended. This includes inspecting the cable and connections for signs of wear or damage, cleaning the area around the cable to prevent debris buildup, and testing the cable periodically to ensure it is functioning correctly. Adhering to these maintenance practices can help prevent issues and ensure the cable continues to operate efficiently 8.

Safety Considerations

When using and maintaining the 3913112 Engine Heater Cable, it is important to follow safety precautions and best practices. This includes handling electrical components with care to avoid shocks or short circuits. Always disconnect the battery before performing any installation or maintenance tasks. Additionally, adhere to the manufacturer’s guidelines for use and maintenance to ensure safe and effective operation of the cable 9.

Compatibility of Engine Heater Cable Part 3913112 with Cummins Engines

The Cummins Engine Heater Cable part number 3913112 is designed to fit a variety of Cummins engines, ensuring efficient heating and starting in cold weather conditions. Here is a detailed look at the compatibility of this part with various Cummins engines:

Small Bore Engines

- QSB3.9 30 CM550

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB5.9 CM850

- QSB6.7 M CM2250

These engines, part of the QSB series, are known for their compact design and versatility. The heater cable part 3913112 is engineered to fit seamlessly with these engines, providing reliable heating capabilities.

Medium Bore Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5

- B5.9 G

- C8.3 G

The medium bore engines in this list, such as the 4B3.9 and 6B5.9, benefit from the heater cable part 3913112. This part ensures that these engines can start efficiently even in colder climates.

High Bore Engines

- ISBE CM800

- ISC CM554

- ISL CM554

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM554

- QSL9 CM850 (CM2850)

The high bore engines, including the ISBE CM800 and QSL9 CM850, are designed for heavy-duty applications. The heater cable part 3913112 is compatible with these engines, ensuring that they can be started reliably in a variety of conditions.

This compatibility ensures that the heater cable part 3913112 can be used across a wide range of Cummins engines, providing a reliable solution for cold weather starting 10.

Role of Part 3913112 Engine Heater Cable in Engine Systems

The Part 3913112 Engine Heater Cable is integral to the operation of several key components within engine systems, particularly in cold climates or during periods of inactivity. This component facilitates the connection and operation of the coolant heater, which is a vital element in the coolant heater starting aid system.

When integrated with the coolant heater, the Engine Heater Cable ensures that the engine block and coolant are preheated before starting. This preheating process reduces the viscosity of the oil, making it easier for the engine to turn over and start. It also helps in achieving optimal operating temperatures more quickly, which is essential for efficient engine performance and reduced wear on engine components.

In conjunction with the coolant heater starting aid, the Engine Heater Cable plays a significant role in enhancing the starting process of the engine. By preheating the coolant, it minimizes the strain on the starter motor and battery, leading to more reliable starts even in adverse conditions. This is particularly beneficial in environments where temperatures drop significantly, as it ensures that the engine components are not subjected to thermal shock.

The integration of the Engine Heater Cable with the heater component ensures that the entire system operates seamlessly. It provides a consistent and reliable source of electrical power to the heater, allowing for precise control over the heating process. This results in uniform heating of the coolant, which is essential for maintaining engine efficiency and longevity.

Furthermore, the Engine Heater Cable works in harmony with the coolant system to ensure that the heated coolant is circulated effectively throughout the engine. This circulation is vital for dissipating heat evenly, preventing hotspots, and ensuring that all engine components reach their optimal operating temperatures simultaneously.

In summary, the Part 3913112 Engine Heater Cable is a key facilitator in the efficient and reliable operation of engine systems, particularly in challenging environmental conditions. Its role in connecting and powering essential components like the coolant heater and coolant heater starting aid underscores its importance in maintaining engine performance and durability 11.

Conclusion

The Cummins 3913112 Engine Heater Cable is a vital component for enhancing the performance and reliability of heavy-duty trucks in cold weather conditions. By pre-heating the engine, it reduces the strain on engine components during start-up, improves fuel efficiency, and ensures quicker warm-up times. Its durable construction, ease of installation, and compatibility with a wide range of Cummins engines make it an essential part for maintaining optimal engine operation in adverse conditions.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Goodnight, Nicholas, and Kirk Van Gelder. Automotive Braking Systems. Jones & Bartlett Learning, 2018.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Cummins Inc. D4.0 CM2620 D103B, Service Manual (5579482).

↩ -

Cummins Inc. D4.0 CM2620 D103B, Service Manual (5579482).

↩ -

Cummins Inc. D4.0 CM2620 D103B, Service Manual (5579482).

↩ -

Cummins Inc. D4.0 CM2620 D103B, Service Manual (5579482).

↩ -

Cummins Inc. D4.0 CM2620 D103B, Service Manual (5579482).

↩ -

Cummins Inc. D4.0 CM2620 D103B, Service Manual (5579482).

↩ -

Cummins Inc. D4.0 CM2620 D103B, Service Manual (5579482).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.