This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

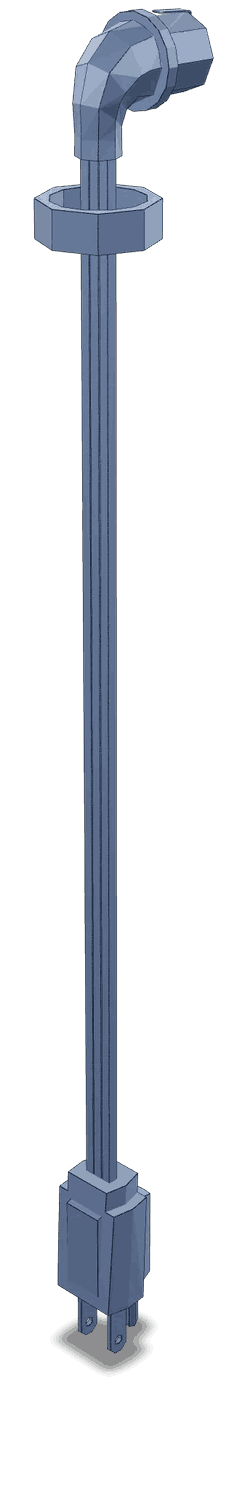

The Cummins 3913106 Engine Heater Cable is designed to facilitate the preheating of diesel engines in heavy-duty trucks. This part ensures efficient engine start-up in cold conditions, which is crucial for the operation of trucks in colder climates or during winter months.

Basic Concepts of Engine Heater Cables

Engine heater cables are electrical components used in the preheating process of diesel engines. They supply electrical current to heating elements within the engine block, warming the engine oil and coolant. This preheating reduces the viscosity of the oil, making it easier for the engine to start and reach optimal operating temperature more quickly. The process is particularly beneficial in cold weather, where diesel fuel can become gel-like and engine components can seize up 1.

Purpose of the Cummins 3913106 Engine Heater Cable

The Cummins 3913106 Engine Heater Cable aids in the preheating of the engine by supplying electrical power to the heating elements, warming the engine oil and coolant. This ensures smoother engine start-ups in cold conditions, reduces the strain on the starter motor, and helps in achieving quicker engine warm-up, which is beneficial for both engine longevity and performance 2.

Key Features

The Cummins 3913106 Engine Heater Cable is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and reliable performance in demanding conditions. The cable is designed to withstand the electrical and thermal stresses associated with engine preheating. Additionally, it features secure connection points to ensure a stable and efficient transfer of electrical power to the heating elements.

Benefits of Using the Cummins 3913106 Engine Heater Cable

Utilizing the Cummins 3913106 Engine Heater Cable offers several advantages. It improves engine start-up in cold weather by reducing the viscosity of engine oil, which facilitates easier cranking and reduces wear on engine components. Moreover, preheating the engine leads to quicker attainment of optimal operating temperature, enhancing overall engine performance and efficiency. It also contributes to the longevity of engine components by minimizing the stress associated with cold starts 1.

Installation and Usage

Proper installation of the Cummins 3913106 Engine Heater Cable is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring secure connections and proper alignment with the engine’s heating elements. Users should follow specific instructions regarding the activation and deactivation of the cable to ensure optimal performance and safety. Regular checks should be performed to ensure the cable remains in good condition and is functioning correctly.

Troubleshooting and Maintenance

Common issues with engine heater cables can include electrical faults, damaged cables, or ineffective heating. Troubleshooting may involve checking the electrical connections, inspecting the cable for physical damage, and ensuring the heating elements are functioning correctly. Maintenance practices include regular inspection of the cable and connections, cleaning any debris or corrosion, and replacing the cable if it shows signs of wear or damage. These practices help in prolonging the lifespan of the cable and ensuring reliable operation 2.

Safety Considerations

When working with engine heater cables, it is important to observe safety precautions. This includes ensuring proper handling of electrical components, adhering to electrical safety standards, and complying with relevant regulations. Users should be aware of the potential risks associated with electrical work and take appropriate measures to mitigate these risks, such as wearing insulated gloves and ensuring the engine is turned off before making any adjustments to the cable.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and commitment to customer success. The company’s product offerings cater to various industries, including transportation, construction, and power generation, providing reliable and efficient power solutions to meet diverse needs.

Cummins Engine Heater Cable 3913106 Compatibility

The Cummins Engine Heater Cable part number 3913106 is designed to fit a variety of Cummins engines. This heater cable is essential for ensuring the engine reaches optimal operating temperatures more quickly, especially in colder climates. Below is a detailed description of the compatibility of this part with various Cummins engines:

4B3.9 and 6B5.9 Engines

The 3913106 heater cable is compatible with the 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications.

6C8.3 and B4.5 Engines

This heater cable also fits the 6C8.3 and B4.5 engines. These engines are typically found in agricultural and construction machinery, providing the necessary power and durability for demanding tasks.

B5.9 G and C8.3 G Engines

The 3913106 part is suitable for the B5.9 G and C8.3 G engines. These engines are designed for high-performance applications, ensuring efficient and reliable operation.

ISB CM550, ISC CM2150, ISC CM554, ISC CM850, ISC8.3 CM2250

The heater cable is compatible with the ISB CM550, ISC CM2150, ISC CM554, ISC CM850, and ISC8.3 CM2250 engines. These engines are part of the Cummins ISB and ISC series, known for their versatility and efficiency in various industrial applications.

ISL CM2150, ISL CM554, ISL9 CM2150 SN, ISL9 CM2250

The 3913106 heater cable fits the ISL CM2150, ISL CM554, ISL9 CM2150 SN, and ISL9 CM2250 engines. These engines are part of the ISL series, offering high performance and reliability for a range of applications.

NH/NT 855

The heater cable is also compatible with the NH/NT 855 engine. This engine is known for its power and efficiency, often used in agricultural and construction equipment.

QSB3.9 30 CM550, QSB5.9 30 CM550, QSB5.9 44 CM550

The 3913106 part fits the QSB3.9 30 CM550, QSB5.9 30 CM550, and QSB5.9 44 CM550 engines. These engines are part of the QSB series, designed for heavy-duty applications requiring high performance and durability.

QSC8.3 CM554, QSC8.3 CM850 (CM2850)

The heater cable is compatible with the QSC8.3 CM554 and QSC8.3 CM850 (CM2850) engines. These engines are part of the QSC series, known for their efficiency and reliability in various industrial applications.

QSC9 CM2250/QSL9 CM2250

The 3913106 part fits the QSC9 CM2250 and QSL9 CM2250 engines. These engines are part of the QSC and QSL series, offering high performance and durability for demanding applications.

QSL8.9 CM2150 L141, QSL9 CM2250, QSL9 CM2350 L102

The heater cable is also compatible with the QSL8.9 CM2150 L141, QSL9 CM2250, and QSL9 CM2350 L102 engines. These engines are part of the QSL series, known for their power and efficiency in various industrial and agricultural applications.

Role of Part 3913106 Engine Heater Cable in Engine Systems

The part 3913106 Engine Heater Cable is an integral component in various engine systems, facilitating efficient and reliable operation in cold weather conditions. This cable is designed to connect the engine’s electrical system to the engine block heater, ensuring that the engine block and coolant are preheated before starting.

Integration with Engine Components

-

Engine Block Heater: The Engine Heater Cable is directly connected to the engine block heater. This connection allows electrical current to flow from the vehicle’s battery or an external power source to the heater. The block heater then warms the engine block, reducing viscosity of the oil and making it easier for the engine to turn over during startup.

-

Coolant Heater: In systems where a coolant heater is used, the Engine Heater Cable ensures that the coolant within the engine is preheated. This is particularly beneficial in diesel engines where thick, cold coolant can impede efficient engine operation. Preheating the coolant helps in achieving optimal engine temperature more quickly, enhancing overall performance.

-

Starting Aid: The Engine Heater Cable acts as a starting aid by ensuring that both the engine block and coolant are at an optimal temperature before ignition. This reduces the strain on the starter motor and battery, leading to more reliable starts in cold conditions.

-

Water Heater: In some engine systems, a water heater is integrated to preheat the water within the cooling system. The Engine Heater Cable provides the necessary electrical connection to this water heater, ensuring that the water is warmed prior to engine startup. This helps in maintaining consistent engine temperature and improving fuel efficiency.

-

Heater Element: The cable is also responsible for powering the heater element within the engine block or coolant system. This element generates heat through electrical resistance, effectively warming the surrounding components.

-

Coolant System: Overall, the Engine Heater Cable plays a significant role in the coolant system by ensuring that the coolant is preheated. This prevents the formation of ice within the coolant passages and reduces the risk of coolant-related issues such as freezing or gelling, which can occur in extremely cold temperatures.

By effectively integrating with these components, the part 3913106 Engine Heater Cable enhances the reliability and performance of engine systems in cold weather, ensuring smoother starts and more efficient operation.

Conclusion

The Cummins 3913106 Engine Heater Cable is a vital component for heavy-duty trucks operating in cold climates. Its role in preheating the engine ensures smoother start-ups, reduces strain on engine components, and enhances overall engine performance and longevity. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.