This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3883216 Engine Brake Cabin Control is designed to facilitate the operation of the engine brake system in heavy-duty trucks. This control allows drivers to engage the engine brake from the cabin, enhancing both safety and efficiency in truck operations.

Basic Concepts of Engine Brake Cabin Control

Engine brake systems decelerate vehicles by converting engine power into resistive force through altered valve timing, creating compression within the cylinders. The cabin control interface allows drivers to activate and manage this system, reducing reliance on friction brakes and improving braking performance 1.

Purpose and Role in Truck Operation

This Cummins part enhances driving safety and efficiency by allowing drivers to engage the engine brake from within the cabin. It reduces reliance on friction brakes, which can lead to overheating and wear, and allows for more controlled descents on inclines 2.

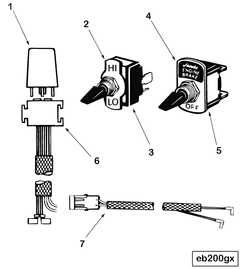

Key Features

The Engine Brake Cabin Control is ergonomically designed for ease of use, with robust build quality to withstand heavy-duty environments. It features precise control mechanisms for fine-tuning engine brake engagement.

Benefits

Benefits include improved braking performance, reduced wear on friction brakes, and enhanced driver control. Utilizing the engine brake allows for more efficient deceleration, prolonging the life of friction brakes and contributing to safer driving practices 3.

Installation and Integration

Proper installation and integration of the 3883216 within a truck’s systems are crucial for optimal performance. It involves connecting the control to the engine’s electronic control unit (ECU) and ensuring all wiring is correctly installed.

Troubleshooting and Maintenance

Common issues may include unresponsive controls or irregular engine brake engagement. Troubleshooting involves checking electrical connections, calibration, and system functionality. Maintenance tips include regular inspection, cleaning, and ensuring secure connections.

Safety Considerations

Safety practices and precautions are important when using the Engine Brake Cabin Control. Driver training, awareness of the control’s functions and limitations, and regular maintenance are necessary for safe and reliable operation.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its innovation and excellence in the automotive and heavy-duty truck industries. The company’s engine brake systems are designed to enhance vehicle performance, safety, and efficiency.

Compatibility with Cummins Engines

The Engine Brake Cabin Control part 3883216 is compatible with several Cummins engine models, including the ISM, L10 and M11, and QSM11 series, ensuring a standardized solution for engine brake management.

Interaction with the Engine

The 3883216 communicates with the engine’s ECU to modulate engine braking, adjusting fuel delivery and ignition timing for controlled deceleration.

Coordination with the Brake System

The control unit ensures a harmonious blend of engine and friction braking, programmable to activate at specific speeds or conditions, enhancing braking efficiency in heavy-duty vehicles.

Enhanced Control Mechanisms

Drivers can fine-tune the engine brake’s intensity through the cabin controls, selecting different levels of engine braking to suit varying road conditions and preferences.

Safety and Performance Benefits

Integrating the 3883216 with engine and brake systems improves safety and performance by reducing brake fade risk, providing better control in adverse conditions, and contributing to fuel efficiency.

Conclusion

The Cummins 3883216 Engine Brake Cabin Control is a sophisticated component that enhances the functionality of engine and brake systems, offering improved safety, performance, and driver control in heavy-duty truck operations.

-

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Hiereth, Hermann, Peter Prenninger, and Klaus W Drexl. Charging the Internal Combustion Engine. Springer, 2010.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.