Introduction

The Cummins 3821854 Engine Heater Housing is a component designed to enhance the operation of commercial trucks, particularly in cold weather conditions. Its purpose is to preheat the engine, ensuring smoother starts and more efficient performance. This part is significant in maintaining the reliability and efficiency of truck engines in various operating environments.

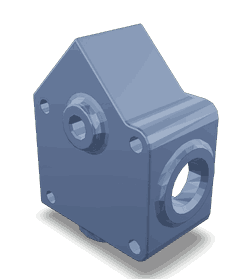

Basic Concepts of Engine Heater Housing

An Engine Heater Housing is a component that encloses and protects the engine heater element. It functions by providing a controlled environment for the heater, allowing it to warm the engine coolant before starting the engine. This process helps in reducing the viscosity of the oil and other fluids, making engine start-up easier and more efficient. The housing plays a role in the overall engine system by ensuring that the heater element operates effectively and safely 1.

Purpose of the Cummins 3821854 Engine Heater Housing

The Cummins 3821854 Engine Heater Housing is specifically designed to preheat the engine in cold conditions. By warming the engine coolant, it facilitates easier engine start-ups, reduces the strain on the starter motor, and enhances overall engine performance. This preheating function is particularly beneficial in extreme cold weather, where engine fluids can become thick and difficult to circulate 2.

Key Features

The Cummins 3821854 Engine Heater Housing features a robust design that ensures durability and reliability. It is constructed from high-quality materials that can withstand the harsh conditions of commercial truck operations. The housing is designed to fit seamlessly with Cummins engines, ensuring proper integration and function. Unique characteristics include its compact design, which allows for easy installation, and its efficient heating capabilities, which contribute to improved engine performance.

Benefits

The Cummins 3821854 Engine Heater Housing offers several benefits. It improves engine start-up in cold weather by preheating the engine, which reduces the viscosity of engine fluids and makes starting easier. This preheating also reduces wear on engine components by allowing them to operate under less stress during start-up. Additionally, the housing enhances overall engine performance by ensuring that the engine reaches optimal operating temperature more quickly 3.

Installation and Integration

Installing the Cummins 3821854 Engine Heater Housing involves integrating it into the truck’s engine system. This process requires ensuring that the housing is properly aligned with the engine’s coolant system and that all connections are secure. Prerequisites for installation include verifying that the engine is compatible with the housing and that all necessary components are in place. Careful attention to these details ensures that the housing functions effectively within the engine system.

Troubleshooting and Maintenance

Common issues with the Cummins 3821854 Engine Heater Housing may include leaks, inefficient heating, or electrical problems. Troubleshooting these issues involves checking for proper installation, ensuring all connections are secure, and verifying that the heating element is functioning correctly. Regular maintenance includes inspecting the housing for signs of wear or damage, ensuring that all seals are intact, and performing routine checks on the electrical connections. These practices help ensure optimal performance and longevity of the housing.

Performance Impact

The Cummins 3821854 Engine Heater Housing impacts the performance of the truck’s engine by improving start-up efficiency in cold weather, which can lead to better fuel efficiency and reduced emissions. By preheating the engine, it allows for smoother operation and reduces the strain on engine components, contributing to overall reliability. The housing also plays a role in maintaining consistent engine performance across varying temperatures.

Safety Considerations

When using and maintaining the Cummins 3821854 Engine Heater Housing, it is important to follow proper safety measures. This includes ensuring that the housing is installed correctly to prevent leaks or malfunctions. Operational safety measures involve monitoring the heating element to ensure it does not overheat and checking for any signs of electrical issues. Proper handling and regular inspections are crucial to maintaining the safety and effectiveness of the housing.

Environmental Impact

The use of the Cummins 3821854 Engine Heater Housing can have a positive environmental impact by reducing the time required for the engine to reach optimal operating temperature. This can lead to lower fuel consumption during start-up and reduced emissions. Additionally, by improving engine efficiency, the housing contributes to overall reductions in fuel use and emissions, aligning with efforts to minimize the environmental footprint of commercial truck operations.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. With a history of innovation and excellence, Cummins offers a wide range of products designed to enhance the performance and reliability of commercial vehicles. The company’s reputation for quality and durability is reflected in its extensive product range, which includes engine components like the Cummins 3821854 Engine Heater Housing.

Integration of Part 3821854 Engine Heater Housing with Engine Systems

The Engine Heater Housing part number 3821854, manufactured by Cummins, is designed to fit seamlessly with the L10 GAS and L10 MECHANICAL engines. This component plays a role in maintaining optimal engine temperature, especially in cold weather conditions, by providing a protective housing for the engine heater.

For the L10 GAS engine, the housing ensures that the heater is securely mounted and insulated, allowing for efficient heat distribution and protection from external elements. Similarly, for the L10 MECHANICAL engine, the housing is engineered to integrate with the engine’s design, ensuring that the heater operates effectively without compromising the engine’s structural integrity.

The part is crafted to fit precisely within the engine’s architecture, ensuring compatibility and ease of installation. Its design allows for a snug fit, minimizing the risk of leaks and ensuring that the heater performs optimally under various operating conditions.

In both engine types, the housing is strategically placed to facilitate the heater’s function, ensuring that the engine reaches its optimal operating temperature quickly and efficiently. This is particularly important for maintaining engine performance and longevity, especially in environments where cold starts are frequent.

By integrating seamlessly with the L10 GAS and L10 MECHANICAL engines, the Engine Heater Housing part number 3821854 from Cummins provides a reliable solution for maintaining engine temperature, enhancing overall engine performance and reliability.

Conclusion

The Cummins 3821854 Engine Heater Housing is a vital component for enhancing the performance and reliability of commercial truck engines, especially in cold weather conditions. Its robust design, efficient heating capabilities, and seamless integration with Cummins engines make it an essential part for maintaining optimal engine operation. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this part.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.