3692032

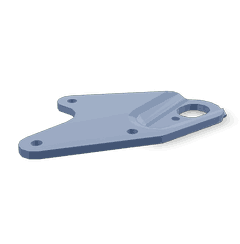

Engine Lifting Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3692032 Engine Lifting Bracket is a specialized component designed for the maintenance and repair of heavy-duty trucks. This part facilitates the safe and efficient removal and installation of engines, ensuring these processes are conducted with precision and care. Its design and functionality are tailored to meet the demanding requirements of heavy-duty truck maintenance, providing a reliable solution for professionals in the field.

Purpose and Function

The Cummins 3692032 Engine Lifting Bracket serves a significant role in the operation of heavy-duty trucks by providing a secure point of attachment for lifting equipment during engine removal and installation. This bracket ensures that the engine is supported and maneuvered safely, reducing the risk of damage to the engine and surrounding components. Its use is integral to maintaining the integrity of the engine during service procedures, allowing for precise alignment and secure handling.

Key Features

The Cummins 3692032 Engine Lifting Bracket is characterized by its robust design and high-quality materials, which contribute to its durability and strength. Constructed from durable materials, this Cummins part is engineered to withstand the significant loads associated with heavy-duty truck engines. Its design ensures compatibility with Cummins engines, providing a secure fit and reliable performance. The bracket’s strength and durability are critical factors in its ability to support heavy engine weights without deformation or failure.

Benefits

Utilizing the Cummins 3692032 Engine Lifting Bracket offers several advantages in the context of engine handling and maintenance. It enhances safety by providing a secure attachment point for lifting equipment, minimizing the risk of accidents during engine removal and installation. Additionally, it improves efficiency in maintenance procedures by allowing for precise engine alignment and secure handling, which can reduce the time required for service operations. The reliability of this bracket in supporting heavy engine weights ensures that maintenance tasks are performed with confidence and accuracy.

Installation Process

Proper installation of the Cummins 3692032 Engine Lifting Bracket involves several steps to ensure it is securely attached and correctly aligned. Begin by gathering the necessary tools, which may include wrenches, sockets, and a torque wrench. Preparatory steps include cleaning the installation area to remove any debris or contaminants that could affect the bracket’s fit. Align the bracket according to the manufacturer’s instructions, ensuring it is positioned correctly relative to the engine and other components. Secure the bracket in place using the appropriate fasteners, torqued to the specified settings to ensure a secure fit.

Troubleshooting and Maintenance

Common issues with the Cummins 3692032 Engine Lifting Bracket may include misalignment, loose fasteners, or damage to the bracket itself. Troubleshooting steps involve inspecting the bracket for signs of wear or damage, ensuring all fasteners are tight, and verifying that the bracket is correctly aligned. Regular maintenance practices, such as cleaning the bracket and inspecting it for damage, can help ensure its longevity and optimal performance. Addressing issues promptly can prevent more significant problems during engine handling.

Safety Considerations

When using the Cummins 3692032 Engine Lifting Bracket, it is important to observe several safety guidelines and precautions. Proper lifting techniques should be employed to avoid accidents, including using the correct lifting equipment and ensuring the bracket is securely attached. Load capacity limitations must be respected to prevent overloading the bracket, which could lead to failure. Additionally, personnel should be trained in the safe use of lifting equipment and the handling of heavy components to minimize the risk of injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance the performance and efficiency of vehicles and equipment. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 1.

Role of Part 3692032 Engine Lifting Bracket in Engine Systems

The 3692032 Engine Lifting Bracket is integral to the arrangement and lifting processes of engine systems. It provides a secure attachment point for lifting equipment, ensuring that the engine can be safely and efficiently moved during maintenance, repair, or installation procedures.

Integration with Engine Components

-

Engine Cradle Attachment: The lifting bracket is typically mounted on the engine cradle, which supports the engine within the vehicle chassis. This setup allows for the entire engine assembly to be lifted without causing undue stress on any single component.

-

Connection to Lifting Equipment: The bracket interfaces directly with lifting equipment such as hoists or cranes. This connection is designed to distribute the lifting force evenly across the engine, minimizing the risk of damage during the lifting process.

-

Alignment with Mounting Points: The bracket is aligned with specific mounting points on the engine block. These points are chosen for their structural integrity, ensuring that the lifting force is applied to the strongest parts of the engine.

-

Use in Engine Removal and Installation: During engine removal, the lifting bracket facilitates a controlled descent, allowing the engine to be lowered into place with precision. Conversely, during installation, it enables the engine to be raised into the engine bay without complications.

-

Support During Maintenance: When the engine is partially removed for maintenance, the lifting bracket can support the engine in a stable position, providing access to underneath components while ensuring the engine remains secure.

-

Facilitation of Alignment: The bracket assists in aligning the engine with transmission and other connected components, ensuring that all parts fit together correctly during reassembly.

By incorporating the 3692032 Engine Lifting Bracket into engine systems, engineers and mechanics can perform lifting operations with greater safety and efficiency, ultimately contributing to the overall integrity and performance of the engine assembly 2.

Conclusion

The Cummins 3692032 Engine Lifting Bracket plays a crucial role in the maintenance and repair of heavy-duty trucks by providing a secure and efficient means of lifting and supporting engines. Its robust design, compatibility with Cummins engines, and the benefits it offers in terms of safety and efficiency make it an indispensable tool for professionals in the field. Proper installation, regular maintenance, and adherence to safety guidelines are essential to ensure the optimal performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.