3681704

Engine Barring Device

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3681704 Engine Barring Device is a specialized tool designed for use in heavy-duty truck engines. Its purpose is to facilitate easier engine turnover during maintenance procedures and to prevent hydrolock, a condition where liquid enters the engine’s cylinders, potentially causing severe damage. This device plays a role in ensuring the smooth operation and longevity of truck engines 1.

Basic Concepts of Engine Barring Devices

An Engine Barring Device is a tool used to manually rotate the engine’s crankshaft. This rotation helps in various maintenance tasks, such as when the engine is not running or during the initial stages of an engine rebuild. By allowing the crankshaft to move freely, the device aids in the even distribution of lubrication, reduces the risk of component seizure, and assists in the alignment of engine parts. In the context of engine maintenance and operation, barring devices are invaluable for ensuring that engines can be turned over without applying excessive force, which could lead to damage 2.

Purpose of the Cummins 3681704 Engine Barring Device

The Cummins 3681704 Engine Barring Device is specifically engineered to integrate seamlessly with Cummins engines. It plays a role in preventing hydrolock by allowing the crankshaft to be rotated, ensuring that any liquid that may have entered the cylinders is expelled. Additionally, it facilitates easier engine turnover during maintenance, reducing the physical effort required and minimizing the risk of injury to the technician. This device ensures that the engine components are properly aligned and lubricated, contributing to the overall efficiency and reliability of the engine 3.

Key Features

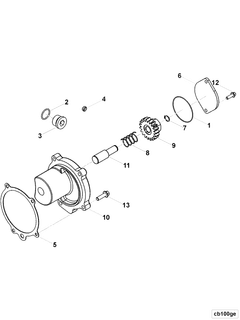

The Cummins 3681704 Engine Barring Device is characterized by its robust design and high-quality materials. It is constructed from durable metals that can withstand the rigors of heavy-duty use. The device features a straightforward yet effective mechanism that allows for smooth rotation of the crankshaft. Its design includes safety features to prevent accidental disengagement during use, enhancing both functionality and durability.

Benefits of Using the Cummins 3681704 Engine Barring Device

Utilizing the Cummins 3681704 Engine Barring Device offers several advantages. It provides improved engine protection by facilitating safe and easy engine turnover, reducing the risk of component damage. The device simplifies maintenance procedures, making them more efficient and less physically demanding for technicians. Over time, its use can lead to potential cost savings by extending the lifespan of engine components and reducing the likelihood of costly repairs due to hydrolock or misalignment.

Installation and Usage Guidelines

To install and use the Cummins 3681704 Engine Barring Device, follow these steps:

- Ensure the engine is turned off and cooled down.

- Locate the barring device installation point on the engine.

- Align the device with the installation point and secure it in place according to the manufacturer’s instructions.

- Rotate the crankshaft using the device, ensuring smooth and even movement.

- After use, remove the device and store it in a safe place.

Always observe safety protocols, such as wearing appropriate personal protective equipment and ensuring the work area is clear of obstacles.

Troubleshooting Common Issues

Common issues with the Cummins 3681704 Engine Barring Device may include difficulty in installation, uneven crankshaft rotation, or device disengagement during use. To address these problems:

- Ensure the device is correctly aligned and securely fastened.

- Check for any obstructions or debris that may be affecting rotation.

- Inspect the device for wear or damage and replace if necessary.

Maintenance Tips

To ensure the longevity and effectiveness of the Cummins 3681704 Engine Barring Device, follow these maintenance practices:

- Regularly clean the device to remove any dirt or grime.

- Inspect for signs of wear or damage after each use.

- Lubricate moving parts as recommended by the manufacturer.

- Replace the device if it shows significant wear or if it fails to function correctly.

Safety Considerations

When using the Cummins 3681704 Engine Barring Device, observe the following safety protocols:

- Always wear appropriate personal protective equipment, including gloves and safety glasses.

- Ensure the engine is turned off and cooled down before installation.

- Keep the work area clear of obstacles and ensure stable footing.

- Follow all manufacturer’s instructions and safety guidelines.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial and industrial applications.

Application in Cummins Engines

The Engine Barring Device 3681704 is compatible with several Cummins engine models, including:

- QSX15 CM570

- QSX15 CM550

- QSX15 CM530

These engines are known for their robust performance and reliability, often used in heavy-duty applications such as commercial trucks, construction equipment, and industrial machinery. The barring device ensures that the engine remains stationary during maintenance, preventing accidental startup and potential injury to technicians.

Installation and Functionality

The installation of the Engine Barring Device 3681704 is straightforward and typically involves securing the device to the engine’s crankshaft. Once installed, it effectively locks the engine in place, preventing any unintentional rotation. This is particularly important during procedures such as timing belt replacement, valve adjustments, and other maintenance tasks that require the engine to be stationary.

Importance in Engine Maintenance

The Engine Barring Device is an indispensable tool for technicians working on Cummins engines. Its primary function is to provide a secure and safe environment during maintenance, ensuring that the engine does not move unexpectedly. This not only protects the technician but also helps in maintaining the precision and accuracy required for various repair and maintenance tasks.

Compatibility and Usage

Given its design and functionality, the Engine Barring Device 3681704 is a versatile component that can be used across multiple Cummins engine models. Its compatibility with the QSX15 series, including the CM570, CM550, and CM530 variants, makes it a valuable tool for technicians working in diverse industrial and commercial settings.

By ensuring the engine remains stationary, the barring device allows for safer and more efficient maintenance procedures, ultimately contributing to the longevity and reliability of the engine.

Role of Part 3681704 Engine Barring Device in Engine Systems

The Engine Barring Device (Part 3681704) is an essential component in the maintenance and operational procedures of various engine systems. Its primary function is to facilitate the rotation of the engine’s crankshaft without the engine being operational. This is particularly important during pre-start checks, post-maintenance inspections, and troubleshooting scenarios.

When integrated with the Drive system, the Engine Barring Device ensures that the crankshaft can be manually or mechanically turned. This is vital for verifying the engine’s mechanical integrity, such as checking for seized components or ensuring that all moving parts operate smoothly. The Drive system, which may include components like the starter motor or an external power source, works in conjunction with the barring device to provide the necessary torque to turn the crankshaft.

In scenarios where the Engine Barring procedure is required, this device plays a significant role. For instance, after major engine repairs or overhauls, it is standard practice to barring the engine to confirm that all repairs have been successful and that there are no obstructions or binding issues within the engine. The Engine Barring Device allows engineers and mechanics to perform this task safely and effectively, minimizing the risk of damage to the engine components.

Additionally, the device is used in conjunction with other engine systems to perform diagnostic checks. By rotating the crankshaft, technicians can observe the operation of various engine subsystems, such as the valve train, piston rings, and cylinder walls, ensuring that they function as intended. This proactive approach helps in identifying potential issues before they lead to more significant problems, thereby enhancing the overall reliability and performance of the engine.

Conclusion

The Cummins 3681704 Engine Barring Device is a critical tool for maintaining the integrity and efficiency of heavy-duty truck engines. By facilitating safe and easy engine turnover, preventing hydrolock, and ensuring proper alignment and lubrication of engine components, this device contributes significantly to the longevity and reliability of Cummins engines. Proper installation, usage, and maintenance of the barring device are essential for maximizing its benefits and ensuring safe and effective engine maintenance procedures.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.