This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

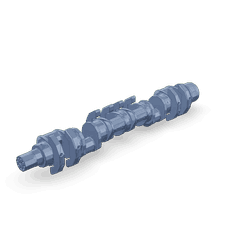

The Cummins 3648638 Engine Crankshaft is a vital component in the engine assembly of commercial trucks. Its purpose is to convert the reciprocating motion of the pistons into rotational motion, which drives the vehicle’s wheels. This crankshaft is significant in ensuring the smooth and efficient operation of the engine, contributing to the overall performance and reliability of the truck.

Basic Concepts of Engine Crankshafts

An engine crankshaft is a mechanical part that plays a central role in the operation of an internal combustion engine. Its primary functions include converting the linear motion of the pistons into rotational motion, which is then transmitted to the transmission system. The crankshaft operates by rotating within the engine block, driven by the force exerted by the pistons as they move up and down in their cylinders 1.

Role of the 3648638 Engine Crankshaft in Truck Operation

The Cummins 3648638 Engine Crankshaft is specifically designed to enhance the operation of commercial trucks. It interacts with various engine components, including the pistons, connecting rods, and the flywheel. The crankshaft’s design allows it to withstand the high stresses and loads generated during engine operation, ensuring consistent power delivery and efficient energy conversion 2.

Key Features of the 3648638 Engine Crankshaft

The Cummins 3648638 Engine Crankshaft boasts several key features that contribute to its performance and durability. Its design incorporates precision engineering to ensure smooth operation and minimal vibration. The materials used in its construction are selected for their strength and resistance to wear, enhancing the crankshaft’s longevity. Additionally, unique characteristics such as balanced counterweights and optimized journal diameters improve the crankshaft’s efficiency and reliability 3.

Benefits of Using the 3648638 Engine Crankshaft

Utilizing the Cummins 3648638 Engine Crankshaft offers several benefits. It contributes to improved engine performance by ensuring efficient power transmission from the pistons to the drivetrain. The crankshaft’s robust design enhances the engine’s reliability, reducing the likelihood of mechanical failures. Furthermore, its efficient operation contributes to better fuel efficiency, making it a valuable component for commercial truck applications 4.

Troubleshooting Common Issues with Engine Crankshafts

Identifying and addressing common issues with engine crankshafts is important for maintaining engine health. Symptoms such as unusual engine vibrations, knocking sounds, or a decrease in engine performance may indicate crankshaft problems. Potential causes include improper lubrication, manufacturing defects, or excessive wear. Regular inspections and maintenance can help identify and resolve these issues before they lead to more significant engine damage 5.

Maintenance Tips for Engine Crankshafts

To ensure optimal performance and longevity of engine crankshafts, regular maintenance is recommended. This includes inspecting the crankshaft for signs of wear or damage, ensuring proper lubrication to reduce friction and wear, and following manufacturer guidelines for replacement intervals. Additionally, maintaining the overall health of the engine, including timely oil changes and filter replacements, contributes to the crankshaft’s durability 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable engines and components. The company’s product range includes a variety of engines and powertrain solutions designed to meet the demanding requirements of commercial vehicles.

Engine Crankshaft Compatibility with Cummins Engines

The Cummins Engine Crankshaft part number 3648638 is a critical component designed to fit seamlessly within various Cummins engine models. This crankshaft is engineered to provide robust performance and reliability, ensuring smooth engine operation across different applications.

K38 Engines

The K38 series engines are known for their durability and efficiency, making them suitable for a wide range of industrial and commercial applications. The Engine Crankshaft part number 3648638 is specifically designed to fit these engines, ensuring optimal performance and longevity. This crankshaft is engineered to withstand the high stresses and demands of these engines, providing a reliable foundation for power generation.

Grouping of Compatible Engines

The Cummins Engine Crankshaft part number 3648638 is not limited to the K38 series alone. It is also compatible with other Cummins engine models that share similar design and operational requirements. This part is engineered to fit seamlessly within these engines, ensuring consistent performance and reliability across different models.

By ensuring that the crankshaft is compatible with a range of Cummins engines, this part provides a versatile solution for maintaining and upgrading engine performance. Its design allows for easy installation and integration, making it a reliable choice for technicians and engineers working with Cummins engines.

Understanding the Integration of Part 3648638 Engine Crankshaft in Engine Systems

The part 3648638 engine crankshaft is a fundamental component that facilitates the conversion of reciprocating motion from the pistons into rotational motion, which is essential for the operation of the engine. This conversion is achieved through the crankshaft’s design, which includes crankpins and counterweights that balance the engine’s operation.

Interaction with Engine Components

-

Pistons and Connecting Rods: The crankshaft interacts directly with the pistons via the connecting rods. As the pistons move up and down within the cylinders, the connecting rods transfer this linear motion to the crankshaft, causing it to rotate. This rotation is the primary source of power for the engine.

-

Flywheel: Connected to the crankshaft, the flywheel plays a significant role in maintaining the engine’s momentum between power strokes. It helps smooth out the engine’s operation by storing rotational energy and releasing it when needed, ensuring consistent power delivery.

-

Timing Chain or Belt: The crankshaft is also linked to the camshaft through a timing chain or belt. This connection ensures that the valves open and close at the correct times relative to the pistons’ movements, maintaining the engine’s timing and efficiency.

-

Main Bearings: These bearings support the crankshaft within the engine block, allowing it to rotate smoothly and minimizing friction. Proper lubrication and maintenance of these bearings are essential for the longevity and performance of the crankshaft.

-

Harmonic Balancer: Attached to the front of the crankshaft, the harmonic balancer reduces vibrations caused by the engine’s operation. It consists of a weighted mass that counteracts the crankshaft’s rotational forces, contributing to a smoother running engine.

-

Oil Pump: In many engine designs, the crankshaft drives the oil pump, which is responsible for circulating lubricant throughout the engine. This lubrication is vital for reducing wear on moving parts and ensuring the engine operates efficiently.

The integration of the part 3648638 engine crankshaft with these components underscores its importance in the engine’s operation. Its design and function are tailored to work in harmony with the engine’s other parts, ensuring efficient power generation and smooth operation.

Conclusion

The Cummins 3648638 Engine Crankshaft is a critical component in the engine assembly of commercial trucks, ensuring efficient power transmission and smooth operation. Its robust design, precision engineering, and compatibility with various Cummins engine models make it a reliable choice for enhancing engine performance and reliability. Regular maintenance and proper integration with other engine components are essential for maximizing the benefits of this part.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 EC (173 HP or Below) Service Manual (2883621).

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 EC (173 HP or Below) Service Manual (2883621).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.