This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

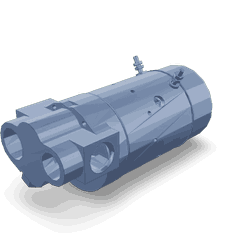

The Cummins 3639044 Engine Lubricating Primer is a component designed to facilitate the start-up process of heavy-duty truck engines by ensuring that critical components are adequately lubricated before the engine begins operation. This part plays a role in the efficient and reliable functioning of the engine, particularly in challenging conditions such as cold weather or after extended periods of inactivity 1.

Function and Operation

The Engine Lubricating Primer operates by pre-lubricating the engine’s vital components, such as the crankshaft, camshaft, and bearings, prior to start-up. This is achieved through a mechanism that activates a small pump, which circulates engine oil through the lubrication system. By ensuring that these components are coated with oil, the primer reduces friction and wear during the initial moments of engine operation, which are typically the most stressful for the engine 2.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. It incorporates advanced technological features such as an electric pump for efficient oil circulation and a control module that activates the primer based on engine conditions. These features contribute to the primer’s effectiveness in enhancing engine performance and longevity 3.

Role in Truck Operation

In the operation of a truck, the Engine Lubricating Primer plays a pivotal role by facilitating smoother and more reliable engine start-ups. This not only improves the overall performance of the truck but also contributes to the longevity of the engine by minimizing wear and tear during start-up. The primer ensures that the engine operates within optimal conditions from the moment it is started, which is particularly beneficial in demanding applications such as heavy-duty trucking.

Benefits

The advantages provided by the Cummins 3639044 Engine Lubricating Primer include improved engine start-up in cold conditions, reduced wear on engine components due to enhanced lubrication during start-up, and enhanced overall engine efficiency. These benefits contribute to the reliability and performance of the truck, making the primer a valuable component in the engine system.

Installation and Integration

Proper installation and integration of the Engine Lubricating Primer into the truck’s engine system require adherence to manufacturer guidelines. This includes ensuring that the primer is correctly connected to the engine’s lubrication system and that all electrical connections are secure. It is also important to verify that the primer is compatible with the specific engine model to ensure optimal performance.

Maintenance and Troubleshooting

Maintaining the Engine Lubricating Primer involves regular checks to ensure that it is functioning correctly. This includes inspecting electrical connections, ensuring the pump operates smoothly, and checking for any signs of wear or damage. Cleaning the primer and its components periodically can also help maintain its efficiency. Common issues may include electrical faults or pump malfunctions, which can often be resolved by checking connections or replacing faulty components.

Safety Considerations

When working with the Engine Lubricating Primer, it is important to observe safety practices and precautions. This includes ensuring that the engine is turned off and cooled down before beginning any work, using appropriate personal protective equipment, and following all manufacturer guidelines for handling, installation, and maintenance. Electrical work should be performed by qualified personnel to avoid risks associated with electrical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in the automotive and heavy-duty truck industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product line and technological advancements have made it a preferred choice for professionals in the industry.

Engine Lubricating Primer Fitment for Cummins Part 3639044

The Cummins Engine Lubricating Primer, part number 3639044, is designed to ensure the proper lubrication of the engine during startup and operation. This primer is compatible with several Cummins engine models, including:

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK78 CM500

The primer is engineered to deliver a measured amount of lubricating oil to the engine’s moving parts, ensuring they are adequately coated and protected from wear and tear. This is particularly important during the initial startup phase when the engine is most vulnerable to damage from friction.

For the QSK60 CM500 and QSK78 CM500, the primer is designed to integrate seamlessly with the engine’s lubrication system, providing a reliable and consistent supply of oil. This ensures that the engine operates smoothly and efficiently, extending its lifespan and maintaining optimal performance.

In the case of the QSK60 CM850 MCRS, the primer is tailored to meet the specific demands of this high-output engine. The MCRS variant requires precise lubrication to handle the increased stress and power output, and the primer is engineered to deliver the necessary oil flow to meet these requirements.

Overall, the Cummins Engine Lubricating Primer, part number 3639044, is a vital component for the reliable operation of these engines, ensuring that they receive the proper lubrication needed for peak performance and longevity.

Integration with Engine Components

-

Crankshaft and Connecting Rods: The primer ensures that the crankshaft and connecting rods receive adequate lubrication before the engine reaches operating speed. This pre-lubrication minimizes metal-to-metal contact, which can lead to excessive wear and potential failure.

-

Camshaft and Valve Train: By delivering oil to the camshaft and valve train components, the primer helps in reducing the friction between these parts. This is particularly important for overhead cam engines where the camshaft is located higher in the engine block.

-

Pistons and Cylinder Walls: The primer plays a role in lubricating the pistons and cylinder walls. This ensures that the piston rings seal properly against the cylinder walls, preventing blow-by and enhancing engine efficiency.

-

Bearings: Main and rod bearings benefit greatly from the primer’s pre-lubrication. These bearings support the crankshaft and connecting rods, and proper lubrication is essential to their longevity and performance.

-

Timing Chain or Belt: For engines equipped with a timing chain or belt, the primer ensures that these components are lubricated before the engine starts. This reduces the risk of premature wear and potential timing issues.

-

Oil Pump: Although the oil pump is responsible for circulating oil once the engine is running, the primer ensures that the pump itself is lubricated before it begins operation. This protects the pump’s internal components from wear.

Operational Sequence

When the ignition is turned on, the primer activates and delivers a measured amount of oil to the critical engine components. This process typically occurs within the first few seconds of startup, ensuring that all moving parts are coated with oil before the engine reaches full operating speed. Once the engine is running and the oil pressure builds up, the main lubrication system takes over, maintaining consistent oil flow to all engine parts.

Conclusion

In summary, the Cummins 3639044 Engine Lubricating Primer is a key component in the pre-lubrication process, significantly contributing to the longevity and efficiency of engine systems. Its role in reducing friction and wear during engine start-up, along with its compatibility with various Cummins engine models, underscores its importance in maintaining optimal engine performance and reliability.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.