This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

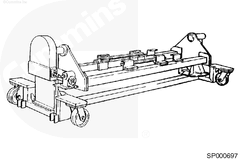

The Cummins 3375990 Engine Repair Stand is a specialized tool designed for the maintenance and repair of heavy-duty truck engines. This equipment is integral to facilitating efficient and safe engine servicing procedures. Its role in the automotive industry underscores the importance of having reliable and robust tools for complex engine work 1.

Purpose and Functionality

This Cummins part serves a pivotal role in the maintenance and repair of heavy-duty truck engines. It is engineered to support the removal, installation, and servicing of engine components. By providing a stable and secure platform, it allows technicians to perform intricate tasks with greater ease and precision. The stand’s design ensures that engines are held firmly in place, reducing the risk of accidents and improving the overall efficiency of repair processes 2.

Key Features

The Cummins 3375990 Engine Repair Stand boasts several primary features that enhance its performance and durability. Its design incorporates high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The stand is capable of supporting significant load-bearing capacities, making it suitable for a variety of engine sizes and weights. Additionally, it includes unique attributes such as adjustable components and ergonomic design elements that contribute to its effectiveness and user-friendliness 3.

Benefits

Utilizing the Cummins 3375990 Engine Repair Stand offers numerous advantages. It enhances safety during engine repairs by providing a stable platform that minimizes the risk of accidents. The stand also increases efficiency in maintenance procedures, allowing technicians to work more quickly and effectively. Furthermore, it ensures enhanced precision in the alignment and installation of engine components, leading to more reliable and durable repairs 4.

Setup and Usage

To properly set up and use the Cummins 3375990 Engine Repair Stand, follow these steps:

- Ensure the stand is placed on a level surface to maintain stability.

- Adjust the height and positioning of the stand to accommodate the specific engine being worked on.

- Securely fasten the engine to the stand using the provided restraints.

- Perform a thorough inspection to confirm that all components are correctly aligned and tightened. Best practices for maximizing the effectiveness of the stand include regular inspections for wear and tear, and ensuring all moving parts are lubricated and functioning correctly.

Troubleshooting and Maintenance

Common issues that may arise when using the Cummins 3375990 Engine Repair Stand include misalignment, component wear, and stability concerns. To address these, perform regular inspections and maintenance checks. Lubricate moving parts as needed and replace worn components promptly. Ensuring the stand is correctly assembled and used according to the manufacturer’s guidelines will help prolong its lifespan and performance.

Safety Considerations

When using the Cummins 3375990 Engine Repair Stand, it is important to observe several safety guidelines and precautions. Ensure that all users are properly trained in the stand’s operation and maintenance. Adhere to safety protocols, such as wearing appropriate personal protective equipment (PPE) and ensuring the work area is clear of obstacles. Regularly inspect the stand for any signs of damage or wear that could compromise safety.

Conclusion

The Cummins 3375990 Engine Repair Stand is an essential tool for the efficient and safe maintenance and repair of heavy-duty truck engines. Its robust design, key features, and benefits make it a valuable asset in any automotive repair facility. Proper setup, regular maintenance, and adherence to safety guidelines are crucial for maximizing its effectiveness and ensuring the safety of technicians.

References

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.