This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

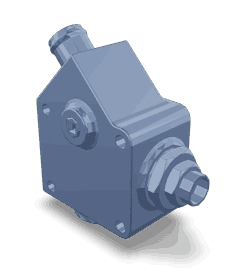

The Engine Heater Top Level Assembly Housing, identified by part number 3329063, is a component manufactured by Cummins. This housing is designed for use in heavy-duty trucks, where it plays a significant role in enhancing engine performance, particularly in cold weather conditions. Cummins, a well-established name in the automotive industry, is known for its commitment to innovation and quality in engine component manufacturing 1.

Function and Operation

The Engine Heater Top Level Assembly Housing is integral to the preheating process of the engine. It facilitates the warming of engine components before startup, which is particularly beneficial in cold climates. By preheating the engine, this housing helps to ensure smoother starts, reduces the strain on engine components during startup, and contributes to overall engine efficiency. The housing works in conjunction with the engine’s cooling system to distribute heat effectively throughout the engine block 2.

Key Features

This assembly housing is characterized by its robust construction, designed to withstand the demanding conditions of heavy-duty truck operations. It is seamlessly integrated with the engine’s cooling system, allowing for efficient heat distribution. Additionally, the housing is compatible with a range of Cummins engines, ensuring versatility across different truck models. Its design also incorporates features that facilitate easy installation and maintenance.

Benefits

The use of the Engine Heater Top Level Assembly Housing offers several advantages. It helps in reducing wear and tear on engine components by ensuring they are at an optimal temperature before operation. This can lead to improved fuel efficiency, as a warm engine operates more efficiently than a cold one. Furthermore, it enhances driver comfort by allowing for quicker warm-up times in cold weather, reducing the need for prolonged idling 3.

Installation and Integration

Proper installation of the Engine Heater Top Level Assembly Housing is crucial for its effective operation. It should be integrated within the truck’s engine system according to the manufacturer’s guidelines. Attention to detail during installation is important to ensure that all connections are secure and that the housing is properly aligned with the engine’s cooling system. Any necessary precautions, such as ensuring the engine is cool before beginning installation, should be observed.

Maintenance and Troubleshooting

Regular maintenance of the Engine Heater Top Level Assembly Housing is important to ensure its longevity and optimal performance. This includes checking for any signs of wear or damage, ensuring all connections are secure, and cleaning the housing as needed. Common issues may include leaks or inefficient heating, which can often be addressed through routine checks and timely repairs.

Safety Considerations

When working with the Engine Heater Top Level Assembly Housing, it is important to follow safety guidelines. This includes ensuring the engine is off and cool before beginning any maintenance or installation work. Adhering to manufacturer recommendations for handling and installation is also crucial to ensure safety and effectiveness.

Environmental Impact

The Engine Heater Top Level Assembly Housing contributes to reduced emissions during cold starts, as a preheated engine tends to emit fewer pollutants. Additionally, by improving engine efficiency, it can lead to decreased fuel consumption over time. This reduction in fuel use not only benefits the environment but also contributes to cost savings for the operator.

Cummins Overview

Cummins has a long-standing reputation in the automotive industry for its innovative and high-quality engine components. The company’s commitment to excellence is evident in its wide range of products, designed to meet the rigorous demands of heavy-duty applications. Cummins continues to lead in the development of advanced engine technologies, ensuring their components are at the forefront of industry standards.

Compatibility with Cummins Engines

The Engine Heater Top Level Assembly Housing, identified by the part number 3329063 and manufactured by Cummins, is designed to fit seamlessly with several Cummins engine models. This housing is a critical component in the engine heater system, providing a protective and functional cover for the heater assembly.

L10 MECHANICAL

The L10 MECHANICAL engine is one of the models that can utilize the 3329063 housing. This engine is known for its robust design and reliability, often used in heavy-duty applications. The housing fits precisely over the heater assembly, ensuring that the heater operates efficiently while being protected from external elements.

M11 CELECT PLUS and M11 MECHANICAL

Both the M11 CELECT PLUS and M11 MECHANICAL engines are compatible with the 3329063 housing. These engines are part of the M11 series, which is renowned for its advanced technology and performance. The housing is engineered to align perfectly with the heater assembly in these engines, facilitating easy installation and optimal performance.

The 3329063 housing is crafted to meet the specific requirements of these engines, ensuring that it provides the necessary protection and functionality. Its design allows for efficient heat transfer while maintaining durability and reliability, making it an ideal choice for these Cummins engines.

Role of Part 3329063 in Engine Systems

The Part 3329063 Engine Heater Top Level Assembly Housing is an integral component in the efficient operation of various engine systems. Its primary function is to facilitate the integration and management of several key systems, ensuring optimal performance and reliability.

Integration with Plumbing Systems

In the context of engine plumbing systems, the Engine Heater Top Level Assembly Housing acts as a central hub. It houses and protects critical components such as hoses, fittings, and sensors. This housing ensures that the plumbing system remains secure and well-organized, reducing the risk of leaks and enhancing the overall efficiency of fluid transfer within the engine. The housing also aids in maintaining consistent fluid temperatures, which is essential for the proper functioning of the engine.

Interaction with Oil Cooler Systems

When it comes to oil cooler systems, the Engine Heater Top Level Assembly Housing plays a significant role in thermal management. It provides a structured environment for the oil cooler lines and associated components. By ensuring that these components are correctly positioned and protected, the housing helps maintain the integrity of the oil cooling process. This, in turn, contributes to the regulation of engine oil temperature, which is vital for lubrication and reducing wear on engine parts.

Coordination with Water Systems

In water systems, the Engine Heater Top Level Assembly Housing is essential for the effective circulation and heating of coolant. It encapsulates components that are responsible for maintaining the correct coolant temperature, which is crucial for engine performance and longevity. The housing ensures that these components are shielded from external elements, thereby enhancing the reliability of the water system. Additionally, it aids in the efficient transfer of heat, ensuring that the engine operates within its optimal temperature range.

Overall, the Part 3329063 Engine Heater Top Level Assembly Housing is a key component that enhances the functionality and reliability of engine systems by providing a secure and organized environment for critical components.

Conclusion

The Engine Heater Top Level Assembly Housing (part number 3329063) is a vital component in the operation of heavy-duty truck engines, particularly in cold weather conditions. Its robust construction, compatibility with various Cummins engines, and role in enhancing engine efficiency and reliability make it an essential part of the engine system. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.