This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3200384 Engine Barring Gear is a specialized component designed for use in heavy-duty truck engines. Its purpose is to facilitate the rotation of the engine crankshaft without the use of the engine’s power, which is particularly useful during engine assembly, disassembly, and maintenance procedures. This component plays a role in ensuring the smooth operation and longevity of truck engines by allowing for safe and controlled engine rotation when the engine is not running.

Basic Concepts of Engine Barring Gear

An engine barring gear is a mechanical device that enables the crankshaft of an engine to be rotated manually or by an external power source. This rotation is necessary for various maintenance procedures, such as aligning components during assembly or disassembly, and for turning the engine over to prevent rust and maintain lubrication in non-operational periods. The barring gear operates by engaging with the flywheel or another component of the crankshaft, providing a means to rotate the engine without starting it 1.

Purpose of the Cummins 3200384 Engine Barring Gear

This Cummins part is specifically designed to integrate with Cummins engines, offering a reliable method for rotating the crankshaft during maintenance and repair operations. It is used to ensure that all moving parts within the engine remain lubricated and free from corrosion when the engine is not in operation. Additionally, it aids in the alignment of engine components during assembly and disassembly, contributing to more efficient and effective maintenance procedures.

Key Features

The 3200384 is characterized by several key features that enhance its functionality and durability. It is constructed from high-strength materials to withstand the rigors of heavy-duty truck engine maintenance. The design includes precise engineering to ensure a secure fit with the engine’s flywheel or crankshaft, minimizing the risk of slippage during operation. Additionally, the gear is designed for ease of use, with features that allow for quick and straightforward installation and removal.

Benefits of Using the Cummins 3200384 Engine Barring Gear

Utilizing this part offers several advantages. It provides enhanced engine protection during periods when the engine is not operational, helping to prevent rust and maintain lubrication of critical components. This gear facilitates easier engine maintenance by allowing for controlled rotation of the crankshaft, which is essential for proper alignment and installation of engine parts. Furthermore, by ensuring that engines are properly maintained, the 3200384 contributes to the overall longevity and reliability of the engine 2.

Installation and Usage Guidelines

Proper installation and usage of this Cummins part involve several steps to ensure safety and effectiveness. First, ensure the engine is cool and disconnected from any power sources. Then, align the barring gear with the flywheel or crankshaft according to the manufacturer’s instructions. Secure the gear in place and use an appropriate tool to rotate the crankshaft slowly and evenly. It is important to follow all safety precautions, including wearing protective gear and ensuring the work area is clear of obstacles.

Troubleshooting and Maintenance

Common issues with the 3200384 may include difficulty in engagement with the flywheel or crankshaft, or signs of wear and tear after prolonged use. Troubleshooting these issues involves checking the alignment and fit of the gear, ensuring it is properly secured, and inspecting for any damage or corrosion. Regular maintenance, such as cleaning the gear and lubricating moving parts, can help prevent issues and ensure optimal performance. If the gear shows significant wear, it may need to be replaced to maintain engine integrity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry, particularly in the heavy-duty truck sector. The company’s product range includes a variety of engines and components designed for durability, efficiency, and performance, making Cummins a trusted name among professionals in the automotive and transportation industries.

Engine Barring Gear Compatibility with Cummins Engines

The Engine Barring Gear, identified by part number 3200384 and manufactured by Cummins, is a component designed to prevent the engine from rotating when it should not. This part is for maintenance and safety purposes, ensuring that the engine remains stationary during certain procedures. Below is a detailed description of how this part fits with various Cummins engines, grouped where applicable.

K19 Series

The K19 series engines are known for their robust design and reliability, often used in heavy-duty applications. The Engine Barring Gear part 3200384 is specifically engineered to fit seamlessly within the K19 engines. Its installation involves securing it to the engine’s crankshaft, ensuring that it can effectively lock the engine in place when needed. This compatibility is crucial for maintenance tasks such as cylinder head removal, timing belt replacement, and other critical procedures that require the engine to be stationary.

Grouping by Application

For engines used in similar applications, the Barring Gear part 3200384 maintains consistent compatibility. For instance, in engines used for construction and agricultural machinery, the Barring Gear ensures that the engine can be safely locked during maintenance, preventing accidental rotation that could lead to injury or damage.

In marine applications, the Barring Gear’s design allows it to withstand the harsh conditions of the marine environment, providing reliable performance even in challenging settings. Similarly, in power generation, the Barring Gear’s precision and durability are essential for maintaining the engine’s operational integrity during maintenance activities.

Installation and Usage

The installation process for the Engine Barring Gear part 3200384 involves aligning it with the engine’s crankshaft and securing it in place using the specified fasteners. Proper installation is critical to ensure that the Barring Gear functions as intended, providing a reliable means to lock the engine during maintenance.

When using the Barring Gear, it is important to follow the manufacturer’s guidelines to avoid any potential issues. This includes ensuring that the engine is completely powered down and that all safety precautions are observed during the installation and use of the Barring Gear.

By understanding the compatibility and installation process of the Engine Barring Gear part 3200384 with Cummins engines, maintenance personnel can ensure that they are using the correct part for their specific engine model, thereby enhancing safety and efficiency during maintenance procedures.

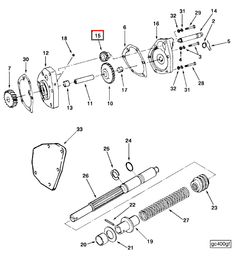

Role of Part 3200384 Engine Barring Gear in Engine Systems

The Part 3200384 Engine Barring Gear is an integral component within the engine barring assembly, designed to facilitate the smooth rotation of the engine during maintenance procedures. This gear is meticulously engineered to interact with various components to ensure the engine’s crankshaft can be turned without the risk of damage.

Interaction with Barring Mechanism

The Engine Barring Gear interfaces directly with the barring mechanism. This interaction allows for controlled rotation of the crankshaft, which is essential during engine start-up, shutdown, or when the engine is not under power. The gear ensures that the rotation is smooth and consistent, preventing any undue stress on the engine components.

Integration with Base Parts

When installed, the Engine Barring Gear is secured to the base parts of the engine system. This setup provides a stable foundation for the gear to operate effectively. The base parts are critical in maintaining the alignment and stability of the gear, ensuring that it functions as intended without any misalignment that could lead to operational issues.

Configuration with Base Parts Less RGt

In certain engine setups, the Engine Barring Gear is used with base parts less RGt (right). This configuration allows for flexibility in engine design, accommodating different engine orientations and setups. The gear’s design ensures compatibility with these variations, maintaining its functionality regardless of the specific base part configuration.

Drive and Barring Functions

The Engine Barring Gear is a key element in the drive and barring functions of the engine. It works in conjunction with the drive mechanism to provide the necessary torque to turn the crankshaft. This is particularly important during maintenance, as it allows technicians to manually rotate the engine for inspection or to relieve pressure within the system.

Engine Barring Assembly

Within the engine barring assembly, the Engine Barring Gear plays a pivotal role. It is responsible for transmitting motion from the barring mechanism to the crankshaft. This assembly is designed to be robust and reliable, ensuring that the engine can be safely rotated without risk of damage to internal components.

Gear & Shaft Coordination

The coordination between the Engine Barring Gear and the shaft is essential for the proper functioning of the engine barring system. The gear must mesh perfectly with the shaft to ensure smooth operation. This interaction is vital for maintaining the integrity of the engine’s moving parts, allowing for precise control over the rotation of the crankshaft.

Conclusion

In summary, the Part 3200384 Engine Barring Gear is a fundamental component in the engine system, ensuring that the crankshaft can be rotated safely and efficiently during various maintenance procedures. Its interaction with other components like the barring mechanism, base parts, and shaft is designed to provide a reliable and effective solution for engine maintenance and operation 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.