This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

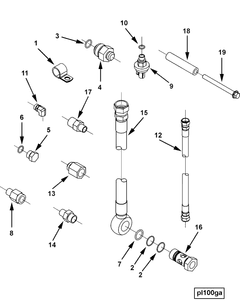

The 3104106 Engine Oil Primer Plumbing is a component designed by Cummins to facilitate the efficient start-up of heavy-duty truck engines. Its purpose is to ensure that oil circulates adequately throughout the engine before ignition, which is vital for the engine’s longevity and performance. This system plays a significant role in the operational readiness of heavy-duty trucks, contributing to their reliability and efficiency 1.

Basic Concepts of Engine Oil Primer Plumbing

Engine oil primer systems are designed to prepare the engine for start-up by ensuring that oil is circulated through critical components before the engine begins to run. This pre-lubrication is crucial for minimizing wear and tear on engine parts during the initial moments of operation 2. The 3104106 operates on this principle, utilizing a series of pipes, valves, and possibly a pump to facilitate the flow of oil to essential areas of the engine.

Role of 3104106 in Truck Operation

This Cummins part contributes to the efficient and reliable operation of heavy-duty trucks by reducing the wear and tear on engine components during start-up. By ensuring that oil is circulated through the engine before it starts, this system helps to create a protective film on moving parts, which is particularly important in the high-stress environment of a heavy-duty truck engine. This pre-lubrication can lead to smoother starts, reduced friction, and potentially extended engine lifespan 3.

Key Features of 3104106

The 3104106 is characterized by its robust design and construction. It is built using high-quality materials that are resistant to the harsh conditions found in heavy-duty truck engines. The system may include unique design elements that enhance its performance and durability, such as precision-machined components and corrosion-resistant coatings. These features contribute to the system’s reliability and effectiveness in ensuring proper oil circulation before engine start-up.

Benefits of Using 3104106

Utilizing the 3104106 offers several advantages. It provides improved engine protection by ensuring that critical components are lubricated before the engine starts. This can lead to enhanced reliability and potentially extend the engine’s lifespan. Additionally, the system contributes to more efficient engine operation by reducing the wear and tear that occurs during start-up, which can be particularly beneficial in the demanding conditions faced by heavy-duty trucks.

Troubleshooting and Maintenance Suggestions

To ensure optimal performance and longevity of the 3104106, it is important to perform routine maintenance tasks and address any issues promptly. Common maintenance tasks may include checking for leaks, ensuring all connections are secure, and verifying that the system is free of debris. If issues arise, such as reduced oil flow or unusual noises, it may be necessary to inspect the system for blockages, worn components, or other problems and take corrective action as needed.

Installation and Compatibility

Proper installation of the 3104106 is crucial for its effective operation. It is designed to be compatible with various Cummins engine models, though specific installation requirements or considerations may apply. Following the manufacturer’s guidelines for installation ensures that the system integrates seamlessly with the engine and operates as intended.

Performance Under Various Conditions

The 3104106 is engineered to perform under a range of operating conditions, including extreme temperatures, high altitudes, and heavy-duty applications. Its design and construction are intended to withstand these challenges, though adjustments or considerations may be needed to ensure optimal performance in particularly demanding environments.

Regulatory Compliance and Standards

The 3104106 meets industry standards and regulatory requirements for safety, performance, and environmental impact. Compliance with these standards ensures that the system operates effectively and responsibly, contributing to the overall reliability and environmental stewardship of heavy-duty truck engines.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins is committed to providing reliable and efficient solutions for the diesel engine and related technologies industry. The company’s product offerings include a wide range of engines and components designed to meet the needs of various industries, from transportation to construction and beyond.

Understanding the Role of Engine Oil Primer Plumbing in Engine Systems

In the intricate network of an engine system, Engine Oil Primer Plumbing (part 3104106) serves a significant function. This component is integral to the lubrication system, ensuring that oil is efficiently circulated throughout the engine, particularly during startup.

Integration with Plumbing Systems

Engine Oil Primer Plumbing is designed to work in conjunction with the overall plumbing of the engine. It facilitates the pre-lubrication of vital engine components before the engine reaches operating speed. This pre-lubrication is essential for reducing wear and tear on parts such as the crankshaft, camshaft, and bearings.

Interaction with the Engine Oil Primer

The engine oil primer, when activated, relies on the plumbing to deliver oil to critical areas of the engine. The primer ensures that oil is present in the necessary passages and components even before the engine starts. This is particularly important in high-performance or large displacement engines where immediate lubrication is required to prevent damage.

Enhanced Lubrication Efficiency

By integrating part 3104106 into the engine’s oil system, the efficiency of lubrication is significantly enhanced. The plumbing ensures that oil reaches all designated points without delay, maintaining a consistent film of lubrication across moving parts. This consistent lubrication is key to prolonging the lifespan of the engine and ensuring smooth operation.

Support for Engine Longevity

The effective use of Engine Oil Primer Plumbing contributes to the overall longevity of the engine. By ensuring that oil is readily available to all critical components, it helps in minimizing friction and heat, which are common culprits behind engine wear. This proactive approach to lubrication is a testament to the importance of well-designed plumbing within engine systems.

Conclusion

In summary, the Engine Oil Primer Plumbing (part 3104106) plays a pivotal role in the lubrication process of engine systems. Its integration with the engine’s plumbing and oil primer ensures that all components receive the necessary lubrication promptly, supporting the engine’s performance and durability.

-

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Michael Klyde and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Allan Bonnick. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.