This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

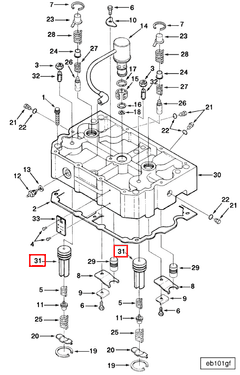

The Engine Brake Slave Piston 3078365, manufactured by Cummins, is a critical component in the operation of heavy-duty trucks. Cummins, a leader in the automotive and heavy-duty truck industry, produces this part to enhance the functionality and efficiency of engine braking systems.

Function and Operation

The Engine Brake Slave Piston 3078365 operates within the engine braking system by interacting with other components to facilitate engine braking. When activated, it works in conjunction with the engine’s valve train to redirect exhaust flow, creating a compression effect that slows the vehicle. This process involves the piston engaging with the engine’s components to modulate the braking force applied 1.

Purpose of the Engine Brake Slave Piston 3078365

The Engine Brake Slave Piston 3078365 plays a role in the engine braking system by aiding in vehicle deceleration and control. It allows for more efficient braking, especially during descents, by utilizing the engine’s compression to slow the vehicle. This reduces reliance on traditional braking systems, thereby extending their lifespan and improving overall vehicle control 2.

Key Features

The Engine Brake Slave Piston 3078365 is characterized by several key features that enhance its performance. Its design is engineered for durability and efficiency, utilizing high-quality materials to withstand the rigors of heavy-duty use. Unique attributes include precision engineering for optimal interaction with the engine’s components and a robust construction that ensures longevity and reliability 3.

Benefits of Using the Engine Brake Slave Piston 3078365

Incorporating the Engine Brake Slave Piston 3078365 into a vehicle’s engine braking system offers several advantages. It contributes to improved braking efficiency, allowing for more controlled deceleration. Additionally, it reduces wear on traditional braking systems by providing an alternative means of slowing the vehicle. This results in enhanced vehicle control during descents and extended maintenance intervals for the braking system 4.

Installation and Integration

Proper installation of the Engine Brake Slave Piston 3078365 within the engine system is crucial for its effective operation. It requires careful alignment with the engine’s components to ensure smooth interaction and optimal performance. Prerequisites for integration may include specific engine modifications or adjustments to accommodate the piston’s operation 5.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Engine Brake Slave Piston 3078365. This includes periodic inspections for wear or damage and cleaning to remove any debris that may affect its operation. Common issues may involve misalignment or wear, which can be addressed through readjustment or replacement as necessary 6.

Safety Considerations

When working with the Engine Brake Slave Piston 3078365, especially during installation, maintenance, or repair procedures, it is important to observe safety guidelines and precautions. This includes ensuring the engine is off and cool before beginning work, using appropriate personal protective equipment, and following manufacturer recommendations to prevent injury or damage 7.

Cummins: A Brief Overview

Cummins Inc. is a leader in the automotive and heavy-duty truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and excellence, Cummins continues to provide solutions that meet the demanding requirements of heavy-duty applications, ensuring performance, efficiency, and durability in its products 8.

Engine Brake Slave Piston (Part 3078365) in Cummins Engines

The Engine Brake Slave Piston, identified by part number 3078365, is a critical component in the operation of the engine brake system in Cummins engines. This part is designed to work seamlessly with the N14 CELECT PLUS and N14 MECHANICAL engines, ensuring efficient and reliable engine braking functionality.

Compatibility with N14 CELECT PLUS

In the N14 CELECT PLUS engine, the Engine Brake Slave Piston plays a pivotal role in the engine’s electronic control system. This part interacts with the engine’s electronic control unit (ECU) to modulate the engine brake’s performance. The precise fit and function of the piston ensure that the engine brake engages and disengages smoothly, providing the necessary resistance to slow down the vehicle without compromising the engine’s overall efficiency.

Compatibility with N14 MECHANICAL

For the N14 MECHANICAL engine, the Engine Brake Slave Piston operates within a more traditional mechanical system. This part is designed to fit perfectly within the engine’s mechanical framework, ensuring that the engine brake provides consistent and dependable performance. The mechanical design of the N14 MECHANICAL engine relies on the precise movement and positioning of the piston to manage the engine brake’s engagement and disengagement, contributing to the engine’s overall reliability and longevity.

Grouping of Engines

Both the N14 CELECT PLUS and N14 MECHANICAL engines benefit from the Engine Brake Slave Piston’s design, which is tailored to meet the specific needs of each engine type. The part’s compatibility with these engines highlights Cummins’ commitment to providing high-quality components that enhance engine performance and durability. By ensuring that the Engine Brake Slave Piston fits seamlessly with both engine types, Cummins maintains a high standard of quality and reliability across its engine lineup.

Role of Part 3078365 Engine Brake Slave Piston in Engine Systems

The Part 3078365 Engine Brake Slave Piston is an integral component within various engine braking systems, facilitating the modulation and application of braking forces in a precise and controlled manner.

Interaction with Brake Systems

In conventional brake systems, the Engine Brake Slave Piston works in concert with the master cylinder and brake calipers. When the brake pedal is depressed, hydraulic pressure is generated within the master cylinder. This pressure is then transmitted through the brake lines to the slave piston, which in turn actuates the brake calipers. The calipers clamp down on the rotors, creating friction that slows the vehicle 9.

Integration with Engine Brake Systems

In engine braking applications, particularly within the Cummins Engine Brake Kit and other engine brake kits, the Engine Brake Slave Piston plays a specialized role. It is responsible for engaging the engine’s braking mechanism, which involves redirecting the engine’s power to create resistance against the vehicle’s motion. This is achieved by manipulating the valve train or using a jake brake system, where the piston controls the opening and closing of specific valves at precise moments to release compressed air, thus decelerating the engine and the vehicle 10.

Control Systems

Modern engine brake systems often incorporate electronic control units (ECUs) that communicate with the Engine Brake Slave Piston. These ECUs receive signals from various sensors monitoring parameters such as vehicle speed, engine RPM, and load. Based on this data, the ECU modulates the slave piston’s operation to optimize braking performance, ensuring smooth and effective deceleration without compromising engine integrity 11.

Enhanced Performance in Cummins Engine Brake Kit

Within the Cummins Engine Brake Kit, the Engine Brake Slave Piston is designed to handle the robust demands of heavy-duty applications. It ensures that the engine brake operates efficiently under varying load conditions, providing reliable retardation force that enhances both safety and fuel efficiency. The piston’s durable construction and precise engineering allow it to withstand the high pressures and temperatures associated with frequent and intense braking scenarios 12.

Comprehensive Brake Kit Applications

In comprehensive brake kits, the Engine Brake Slave Piston is often paired with other advanced components to deliver superior braking performance. These kits may include high-performance brake pads, rotors, and enhanced hydraulic systems, all working in unison with the slave piston to provide maximum stopping power and control 13.

Engine Brake Modulation

The modulation capabilities of the Engine Brake Slave Piston are particularly important in scenarios requiring fine-tuned braking, such as descending steep grades or navigating through traffic. By allowing for adjustable brake force, the piston helps maintain vehicle stability and control, reducing the risk of brake fade and ensuring consistent performance over time 14.

Conclusion

The Engine Brake Slave Piston 3078365 is a versatile and essential component across various brake and engine brake systems, contributing to the overall safety, efficiency, and performance of the vehicle. Its integration into Cummins engines enhances engine braking functionality, providing reliable and efficient deceleration, and extending the lifespan of traditional braking systems.

-

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩ -

Cummins Inc. (n.d.). Service Manual (5677316).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.