This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2873886 Engine Lifting Bracket is a specialized component designed for the maintenance and repair of heavy-duty trucks. This bracket is integral to the process of safely and efficiently removing and installing truck engines. Its role in facilitating these operations underscores its significance in the maintenance industry, ensuring that engine work is performed with precision and safety.

Purpose and Function

The Cummins 2873886 Engine Lifting Bracket serves a pivotal role in the operation and maintenance of truck engines. It is specifically designed to aid in the removal and installation of engines, providing a secure point of attachment for lifting equipment. This bracket ensures that the engine can be handled with stability and control, reducing the risk of damage to the engine and surrounding components during these processes 1.

Key Features

The Cummins 2873886 Engine Lifting Bracket is characterized by its robust design and high-quality materials, which contribute to its durability and reliability. Crafted from materials that can withstand the rigors of heavy-duty use, this bracket is engineered to be compatible with Cummins engines. Its design includes features that enhance its functionality, such as precise fitting and secure attachment points, ensuring it meets the demands of professional engine maintenance 2.

Benefits

Utilizing the Cummins 2873886 Engine Lifting Bracket offers several advantages. It enhances safety during engine handling by providing a stable and secure attachment point for lifting equipment. This reduces the likelihood of accidents and injuries. Additionally, it contributes to a reduction in maintenance time by streamlining the engine removal and installation processes. Proper use of this bracket also aids in the enhancement of overall engine performance through accurate and secure installation 3.

Installation Process

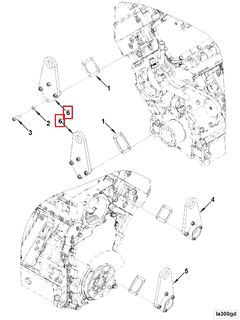

Installing the Cummins 2873886 Engine Lifting Bracket requires adherence to best practices and safety precautions. The process involves securing the bracket to the engine in the designated location, ensuring it is firmly attached before any lifting operations commence. It is important to follow the manufacturer’s guidelines for installation to ensure effective use and safety.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 2873886 Engine Lifting Bracket, regular maintenance is recommended. This includes inspecting the bracket for any signs of wear or damage and ensuring all attachment points are secure. Common issues may include loosening of the bracket or damage from use, which can often be addressed through re-securing or replacement of the affected components.

Compatibility and Usage

The Cummins 2873886 Engine Lifting Bracket is designed for use with specific Cummins engines, ensuring compatibility and optimal performance. Its applicability extends to various truck models and maintenance scenarios, making it a versatile tool in the arsenal of professionals working in the heavy-duty truck industry.

Safety Considerations

When using the Cummins 2873886 Engine Lifting Bracket, it is important to observe safety guidelines and precautions. This includes the use of personal protective equipment and adherence to safe handling practices. Ensuring that all personnel are trained in the proper use of the bracket and lifting equipment is crucial for maintaining a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the automotive industry, Cummins has established itself as a key player in the production of diesel engines and related components, serving a wide range of industries with reliable and high-performance products.

Cummins Engine Lifting Bracket 2873886 Compatibility

The Cummins Engine Lifting Bracket part number 2873886 is a critical component designed to facilitate the safe and efficient lifting of specific Cummins engines. This part is engineered to fit seamlessly with a range of Cummins engines, ensuring compatibility and reliability during maintenance and installation processes.

VTA903 and CM2250 Engines

The VTA903 and CM2250 engines are part of Cummins’ lineup of high-performance diesel engines. These engines are known for their robust construction and are commonly used in various industrial and commercial applications. The Engine Lifting Bracket 2873886 is specifically designed to interface with these engines, providing a secure mounting point for lifting equipment. This ensures that the engine can be lifted without risk of damage, streamlining maintenance procedures and enhancing safety.

V105 Engine

The V105 engine, another member of Cummins’ engine family, is engineered for durability and efficiency. This engine is often utilized in heavy-duty applications, where reliability and performance are paramount. The Engine Lifting Bracket 2873886 is tailored to fit the V105 engine, offering a robust solution for lifting and positioning the engine during maintenance or installation. Its design ensures that the bracket can withstand the stresses associated with lifting heavy engines, providing peace of mind for technicians and operators.

Grouping for Efficiency

When working with the VTA903, CM2250, and V105 engines, the use of the Cummins Engine Lifting Bracket 2873886 is highly recommended. This part is engineered to provide a standardized solution for lifting these engines, reducing the need for multiple specialized brackets. By using a single part across multiple engine models, maintenance and installation processes can be streamlined, leading to increased efficiency and reduced downtime.

Understanding the Role of Part 2873886 Engine Lifting Bracket in Engine Systems

When working with engine systems, the integration of various components ensures the smooth operation and maintenance of the engine. Part 2873886, the Engine Lifting Bracket, plays a significant role in this ecosystem.

Integration with Engine Components

The Engine Lifting Bracket is designed to provide a secure point of attachment for lifting and moving the engine during maintenance or replacement procedures. This bracket interfaces directly with the engine block, often near the cylinder head or sump, depending on the engine’s design.

Interaction with Supporting Structures

In conjunction with a crane or hoist, the lifting bracket allows for the safe elevation of the engine. It ensures that the weight is distributed evenly, reducing the risk of damage to the engine or surrounding components. The bracket must be properly aligned with the engine’s structural points to maintain stability during the lift.

Coordination with Maintenance Tools

During engine removal, the lifting bracket works in tandem with various maintenance tools such as torque wrenches, socket sets, and pry bars. These tools are used to disconnect the engine from its mounts, exhaust system, and ancillary components like the alternator and A/C compressor before the lifting process begins.

Role in Engine Installation

Conversely, when installing a new or repaired engine, the lifting bracket facilitates the precise positioning of the engine into the engine bay. It allows for controlled descent and alignment with the transmission, mounts, and other critical components, ensuring a smooth and damage-free installation.

Safety and Efficiency

The use of the Engine Lifting Bracket enhances both safety and efficiency in engine handling. It minimizes the physical strain on mechanics and reduces the likelihood of accidents associated with improper lifting techniques. Additionally, it streamlines the engine replacement process, allowing for quicker turnaround times in maintenance operations.

Conclusion

The Cummins 2873886 Engine Lifting Bracket is an essential tool for the safe and efficient maintenance of heavy-duty truck engines. Its robust design, compatibility with specific Cummins engines, and role in enhancing safety and efficiency make it a valuable component in the maintenance industry. Regular maintenance and proper use of this bracket ensure optimal performance and longevity, contributing to the overall reliability and performance of the engines it serves.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.