2864488

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Electronic Control Module (ECM) Wiring Harness, part number 2864488, is a critical component designed for use in commercial trucks. This article provides an overview of the wiring harness, its function, key features, benefits, and maintenance suggestions.

Basic Concepts

An ECM Wiring Harness is a bundle of wires and connectors that link the ECM to various sensors, actuators, and other electronic components within a truck. The ECM uses these connections to monitor and control engine functions, transmission operations, and other systems.

Purpose and Function

The Electronic Control Module Wiring Harness plays a role in facilitating communication between the ECM and various components within the truck. It ensures that data and power are correctly transmitted, allowing the ECM to effectively manage engine performance, fuel efficiency, and emissions control.

Key Features

- Robust Construction: Designed to withstand the harsh environments typical of commercial trucking 1.

- High-Quality Materials: Utilizes durable materials to ensure longevity and reliability.

- Precise Engineering: Ensures accurate fit and function within the truck’s electrical system.

- Comprehensive Coverage: Connects multiple sensors and actuators, providing comprehensive system integration.

Benefits

- Enhanced Performance: Contributes to optimal engine performance and fuel efficiency.

- Improved Reliability: Reduces the risk of electrical failures and improves system reliability.

- Simplified Diagnostics: Facilitates easier troubleshooting and maintenance by providing a structured pathway for data and power transmission.

- Compliance with Standards: Meets industry standards for safety and performance.

Compatibility with Cummins Engines

The ECM Wiring Harness (2864488) is specifically engineered to fit the ISM CM570 and QSM11 CM570 engines. These engines are part of Cummins’ lineup of industrial and marine engines, known for their robust performance and durability. The harness is designed to integrate perfectly with the ECM of these engines, ensuring that all electrical signals are transmitted accurately and without interference 2.

Integration with Engine Components

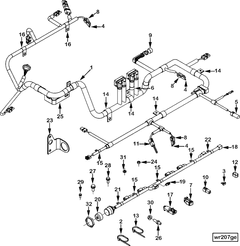

- Sensors: The harness connects the ECM to an array of sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors. These sensors provide real-time data on air intake, fuel mixture, and exhaust emissions, allowing the ECM to make precise adjustments for optimal engine performance.

- Actuators: It interfaces with actuators like the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. The ECM uses data from the sensors to send signals through the harness to these actuators, controlling fuel delivery, air intake, and valve timing for efficient combustion.

- Ignition System: The harness also links the ECM to the ignition system components, including the ignition coils and spark plugs. This connection ensures that the ignition timing is accurately controlled based on engine load and speed, enhancing combustion efficiency and reducing emissions.

- Emission Control Systems: It facilitates communication between the ECM and emission control components such as the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. This ensures that the engine meets environmental regulations by minimizing harmful emissions.

- Battery and Alternator: The harness includes connections to the battery and alternator, allowing the ECM to monitor electrical system health and manage power distribution to various engine components.

- Communication Networks: In many modern vehicles, the ECM Wiring Harness is part of a larger communication network, such as the Controller Area Network (CAN) bus. This network allows the ECM to share data with other control modules in the vehicle, such as the transmission control module or the anti-lock braking system (ABS) module, for coordinated vehicle performance.

Troubleshooting and Maintenance

Regular inspection of the wiring harness for signs of wear, corrosion, or damage is recommended. Any detected issues should be addressed promptly to prevent potential failures. Cleaning the harness and ensuring all connections are secure can help maintain its functionality. Following the manufacturer’s guidelines for maintenance and repair is advised.

Conclusion

The ECM Wiring Harness (2864488) by Cummins is a vital component in the operation of commercial trucks, ensuring efficient and reliable communication between the ECM and various engine components. Its robust construction, high-quality materials, and precise engineering make it a reliable choice for maintaining optimal engine performance and fuel efficiency. Regular maintenance and prompt attention to any issues are essential for ensuring the longevity and effectiveness of this part.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.