5483719

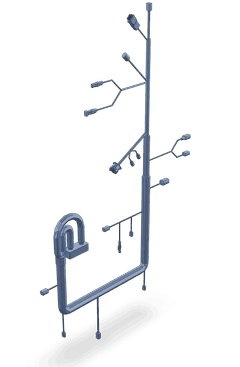

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #5483719) by Cummins is a vital component in the realm of heavy-duty trucks. This wiring harness is integral to the operation of the vehicle’s electronic systems, ensuring seamless communication between various electronic components. Manufactured by Cummins, a renowned name in the automotive industry, this wiring harness is designed to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts

Electronic Control Module Wiring Harnesses serve as the backbone of a vehicle’s electronic system. They facilitate the transmission of electrical signals between the Electronic Control Module (ECM) and other electronic components within the engine management system. This communication is essential for the proper functioning of the engine, as it allows for precise control over various parameters such as fuel injection, ignition timing, and emissions control 2.

Purpose and Functionality

The 5483719 Electronic Control Module Wiring Harness plays a significant role in the operation of a truck by connecting various electronic components and enabling communication within the engine management system. It acts as a conduit for electrical signals, ensuring that the ECM can effectively monitor and control the engine’s performance. This wiring harness is responsible for transmitting data between sensors, actuators, and the ECM, allowing for real-time adjustments to optimize engine operation 3.

Key Features

The 5483719 Electronic Control Module Wiring Harness boasts several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors, ensuring durability in harsh operating conditions. The wiring harness is engineered to meet stringent industry standards, providing a reliable connection between electronic components. Additionally, it features robust connectors and terminals that ensure a secure and stable connection, minimizing the risk of electrical issues.

Benefits

The 5483719 Electronic Control Module Wiring Harness offers a range of benefits that contribute to improved engine performance and overall vehicle efficiency. By facilitating seamless communication within the engine management system, it enables precise control over engine parameters, resulting in enhanced fuel efficiency and reduced emissions. Furthermore, its robust construction ensures reliability in demanding environments, minimizing the risk of electrical failures and downtime.

Troubleshooting and Maintenance

Common issues that may arise with Electronic Control Module Wiring Harnesses include loose connections, damaged wires, and corrosion. Regular inspection and maintenance are crucial to identify and address these issues promptly. Ensuring that connectors are securely fastened and wires are free from damage can help prevent electrical problems. Additionally, applying protective coatings to the wiring harness can mitigate the effects of corrosion and extend its lifespan.

Cummins Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and alternative fuel engines, as well as related technologies. With a rich history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s commitment to advancing engine technology and providing comprehensive solutions has made it a trusted partner for heavy-duty truck manufacturers and operators worldwide.

Cummins Engine Compatibility with Electronic Control Module Wiring Harness Part 5483719

The Electronic Control Module (ECM) Wiring Harness part 5483719, manufactured by Cummins, is a critical component for the proper functioning of the engine’s electronic control systems. This wiring harness is designed to ensure seamless communication between the ECM and various sensors, actuators, and other electronic components within the engine.

QSK19 CM500 Engine

The QSK19 CM500 engine is part of Cummins’ QSK series, which is known for its robust design and high performance in various industrial applications. The ECM Wiring Harness part 5483719 is specifically engineered to fit the QSK19 CM500 engine, providing a reliable and efficient electrical connection. This ensures that the engine’s control module can accurately monitor and manage engine performance, fuel injection, and emissions control systems.

Grouping of Engines

While the QSK19 CM500 is a standalone model, it is part of a broader family of Cummins engines that share similar design principles and compatibility with certain components, including the ECM Wiring Harness part 5483719. Other engines within the QSK series may also utilize this wiring harness, ensuring a standardized approach to engine management and control across different models. This compatibility allows for easier maintenance and repair, as technicians can use the same wiring harness across multiple engine types within the series.

Role of Part 5483719 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 5483719, is an integral component in the orchestration of modern engine systems. This wiring harness serves as the vital link between the Engine Control Module (ECM) and various sensors, actuators, and other electronic components within the engine system.

Integration with the Engine Control Module (ECM)

At the heart of the engine management system lies the ECM, a sophisticated computer that monitors and controls engine operations. The ECM Wiring Harness facilitates seamless communication between the ECM and other engine components. It ensures that the ECM receives accurate data from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. This data is essential for the ECM to make precise adjustments to fuel injection, ignition timing, and other parameters, optimizing engine performance and efficiency.

Connection to Actuators

The ECM Wiring Harness also plays a pivotal role in transmitting commands from the ECM to various actuators. These actuators include the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. By delivering these commands with precision, the wiring harness ensures that the engine operates smoothly and efficiently under varying conditions.

Interaction with Emission Control Systems

In addition to its role in engine performance, the ECM Wiring Harness is instrumental in managing emission control systems. It connects the ECM to components such as the Exhaust Gas Recirculation (EGR) valve and the Evaporative Emission Control (EVAP) system. This connectivity allows the ECM to regulate emissions, ensuring compliance with environmental standards while maintaining optimal engine performance.

Support for Diagnostic Systems

Modern engine systems are equipped with sophisticated diagnostic capabilities, and the ECM Wiring Harness is central to these functions. It provides the necessary connections for On-Board Diagnostics (OBD) systems, allowing for real-time monitoring of engine health and the detection of potential issues. This proactive approach to maintenance helps prevent costly repairs and ensures the longevity of the engine.

Facilitation of Advanced Features

The ECM Wiring Harness also supports advanced engine features such as start-stop systems, cylinder deactivation, and hybrid powertrain integration. By providing the necessary electrical connections, it enables these features to function seamlessly, enhancing overall vehicle performance and fuel economy.

Conclusion

In summary, the ECM Wiring Harness, part number 5483719, is a cornerstone of modern engine management systems. Its role in connecting the ECM to a wide array of sensors, actuators, and diagnostic systems underscores its importance in ensuring engine efficiency, performance, and compliance with emission standards.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ -

Hannes Hick, Klaus Kupper, and Helfried Sorger, Systems Engineering for Automotive Powertrain Development, Springer, 2021.

↩ -

A. J. Wharton, Diesel Engines, Butterworth-Heinemann Ltd, 1991.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.