5442715

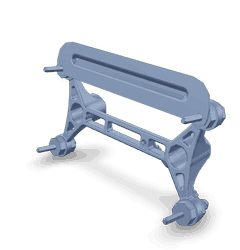

Electronic Control Module Bracket

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5442715 Electronic Control Module Bracket, manufactured by Cummins, is a component designed to secure and protect the Electronic Control Module (ECM) within the engine management system of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of truck operations. This part is significant as it ensures the ECM remains safely housed and operational under various driving conditions.

Function and Operation

This Cummins part plays a role in securing and protecting the Electronic Control Module (ECM) within a truck’s engine management system. By firmly holding the ECM in place, the bracket helps prevent damage from vibrations and impacts that occur during operation. This secure mounting contributes to the overall functionality and reliability of the ECM, ensuring that it can accurately monitor and control engine operations, which is vital for maintaining optimal performance and fuel efficiency 1.

Key Features

The 5442715 is constructed from durable materials, designed to withstand the harsh environments typical of commercial trucking. Its design includes features such as precise mounting points and robust construction, which enhance its performance and durability. These characteristics ensure that the bracket can effectively protect the ECM over the long term, even under demanding conditions.

Benefits

This part offers several advantages. It provides improved protection for the ECM, safeguarding it against physical damage and environmental factors. This protection contributes to enhanced stability of the ECM within the engine compartment. Additionally, by ensuring the ECM remains securely in place and operates efficiently, the bracket may play a part in increasing engine efficiency and longevity.

Installation and Compatibility

Proper installation of the Electronic Control Module Bracket is important for ensuring its effectiveness. Installation guidelines should be followed to secure the bracket correctly and ensure it functions as intended. Compatibility with various truck models and engine types is a consideration, and it is important to verify that the bracket is suitable for the specific application to ensure optimal performance and protection for the ECM 2.

Maintenance and Troubleshooting

Routine maintenance of the 5442715 is recommended to ensure its longevity and effectiveness. This may include checking for signs of wear or damage and ensuring that the bracket remains securely fastened. Common issues that may arise include loosening of the bracket or damage from environmental factors. Troubleshooting steps may involve re-securing the bracket or replacing it if damage is detected.

Safety Considerations

When working with the 5442715, it is important to observe safety guidelines and precautions. This includes proper handling during installation and maintenance to avoid injury or damage to the component. Following manufacturer recommendations for installation and maintenance procedures can help ensure the safety and effectiveness of the bracket.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products that enhance the performance and reliability of trucks. The company has a history of innovation and quality, with a product portfolio that includes engines, powertrains, and various components designed to meet the demands of commercial transportation. Cummins’ reputation within the industry is built on its commitment to quality, performance, and customer satisfaction.

Electronic Control Module Bracket for Cummins Engines

The Electronic Control Module (ECM) Bracket, part number 5442715, is a component in the Cummins engine ecosystem. This bracket is designed to securely mount the ECM, ensuring that the electronic control unit is properly positioned and protected within the engine compartment.

Compatibility with Cummins Engines

The ECM Bracket 5442715 is specifically engineered to fit seamlessly with several Cummins engine models, including:

- F3.8 CM2350 F128C

- Other Cummins Engines

This bracket is integral to the proper functioning of the ECM, which is responsible for managing various engine parameters such as fuel injection, ignition timing, and emissions control. By providing a stable mounting point, the bracket ensures that the ECM remains in the correct orientation, which is crucial for maintaining optimal engine performance and reliability.

Installation and Functionality

When installing the ECM Bracket 5442715, it is essential to follow the manufacturer’s guidelines to ensure a secure fit. The bracket typically attaches to specific mounting points on the engine block, often using bolts or screws. Proper installation is vital for the ECM to communicate effectively with other engine components and to prevent any potential damage due to vibrations or movement.

The ECM Bracket 5442715 is a testament to Cummins’ commitment to quality and precision engineering. Its design ensures that the ECM is held firmly in place, allowing for consistent and reliable engine operation across various applications and conditions.

Conclusion

The 5442715 Electronic Control Module Bracket is an essential component in the integration of the ECM within various engine systems. This bracket is designed to securely mount the ECM, ensuring it remains stable and protected during engine operation. In the context of engine control systems, the ECM bracket facilitates the connection between the ECM and other vital components such as sensors, actuators, and the engine control unit (ECU). It allows for organized routing of wiring harnesses, reducing the risk of damage to sensitive electronic components. The bracket also plays a role in thermal management by allowing proper airflow around the ECM, which is important for maintaining optimal operating temperatures. Additionally, it aids in vibration damping, which is important for the longevity and reliability of the ECM in a dynamic engine environment. Overall, the ECM bracket is a foundational element that supports the efficient and effective operation of the engine control module within the engine system 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.