This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5419193 Electrical Connector is a specialized component designed for use in commercial truck operations. Its purpose is to facilitate secure and reliable electrical connections within the truck’s electrical system. This connector plays a role in ensuring the proper functioning of various electrical components and systems in commercial trucks, contributing to overall vehicle performance and safety 1.

Basic Concepts of Electrical Connectors

Electrical connectors are devices used to join electrical circuits together, allowing the transfer of electrical signals and power between different components. They function by providing a secure and consistent connection point, which is crucial for the reliable operation of vehicle electrical systems. These connectors are integral to the functionality of a vehicle’s electrical network, enabling communication between the battery, sensors, control units, and other electrical components 2.

Purpose of the 5419193 Electrical Connector

This Cummins part is specifically designed to serve as a reliable connection point within a truck’s electrical system. It plays a role in ensuring that electrical signals and power are efficiently transmitted between various components. This connector is part of the broader electrical network that supports the operation of critical systems such as engine management, lighting, and diagnostic systems 3.

Key Features

The 5419193 Electrical Connector is characterized by several key features that enhance its functionality and reliability. Its design incorporates robust materials that are resistant to corrosion and wear, ensuring durability in demanding commercial truck environments. Additionally, the connector features a secure locking mechanism that prevents accidental disconnections, maintaining consistent electrical connections. The design also includes provisions for easy installation and maintenance, facilitating efficient use in field conditions.

Benefits

The 5419193 Electrical Connector offers several advantages that contribute to its effectiveness in commercial truck applications. Its reliable design ensures consistent electrical connections, reducing the risk of system failures. The durability of the materials used in its construction allows it to withstand the harsh conditions often encountered in commercial truck operations. Furthermore, the efficient design of the connector contributes to the overall electrical system’s performance, enhancing the truck’s operational efficiency.

Installation Process

Proper installation of the 5419193 Electrical Connector is crucial for ensuring its effectiveness and the reliability of the electrical system. The installation process involves several steps: first, ensuring the connector and mating components are clean and free from debris; second, aligning the connector with its mating component; third, pressing the connector into place until the locking mechanism engages; and finally, verifying the connection is secure and functions as intended. Tools required may include a crimping tool for terminal preparation and a torque wrench for securing any fasteners.

Common Issues and Troubleshooting

Electrical connectors, including the 5419193, may encounter issues such as corrosion, loose connections, or damage from physical stress. Troubleshooting these issues involves inspecting the connector for signs of wear or damage, cleaning the connection points to remove any corrosion, and ensuring the locking mechanism is engaged properly. In cases where the connector is damaged, replacement may be necessary to restore reliable electrical connections.

Maintenance Tips

Regular maintenance of the 5419193 Electrical Connector is important for ensuring its longevity and proper function. Maintenance practices include periodic inspection for signs of wear or damage, cleaning the connector and its mating components to prevent corrosion, and verifying the security of the connection. Additionally, protecting the connector from physical stress and environmental factors can help maintain its performance over time.

Safety Considerations

When working with electrical connectors in commercial trucks, it is important to follow safety guidelines to prevent injury and ensure the safe operation of the vehicle. This includes wearing appropriate personal protective equipment, ensuring the vehicle’s electrical system is de-energized before working on connectors, and following manufacturer guidelines for installation and maintenance. Adhering to these safety practices helps protect both the technician and the vehicle’s electrical system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for a variety of applications. The company’s dedication to excellence is reflected in its product range, which includes components like the 5419193 Electrical Connector, designed to meet the demanding requirements of commercial truck operations.

Cummins Electrical Connector 5419193 Compatibility

The Cummins Electrical Connector part number 5419193 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connections and optimal performance. This connector is specifically engineered to fit within the electrical systems of the QSK60, CM850, and MCRS engines, providing a robust and dependable solution for various applications.

For the QSK60 engine, the 5419193 connector is integral to maintaining the integrity of the engine’s electrical network. It ensures that all necessary electrical signals are transmitted accurately, which is crucial for the engine’s performance and longevity.

In the CM850 engine, the 5419193 connector plays a pivotal role in the engine’s electrical architecture. Its precise fit and reliable connection capabilities are essential for the smooth operation of the engine’s various electrical components.

The MCRS engine also benefits from the 5419193 connector, which is designed to handle the specific electrical demands of this engine model. Its compatibility with the MCRS ensures that the engine’s electrical systems function without interruption, contributing to the overall efficiency and reliability of the engine.

By integrating the 5419193 connector into the QSK60, CM850, and MCRS engines, Cummins ensures that these engines can operate with maximum efficiency and reliability, supported by a well-maintained electrical system.

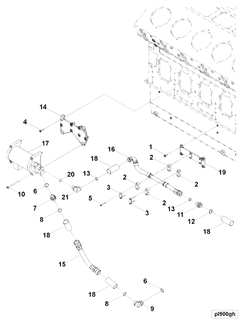

Role of Part 5419193 Electrical Connector in Engine Systems

Part 5419193 Electrical Connector is integral to the seamless operation of various engine systems. In the Current Support Control system, this connector ensures the stable and reliable transmission of electrical signals necessary for maintaining the desired current levels. This is essential for the precise operation of electronic control units (ECUs) that manage fuel injection, ignition timing, and other critical engine functions.

Within the Engine Lubricating Primer system, the 5419193 Electrical Connector facilitates the electrical connection required to activate the primer. This system is responsible for ensuring that the engine’s lubrication system is adequately pressurized before startup, which is vital for reducing wear and tear during the initial phases of engine operation.

In the Engine Lubrication Primer Arrangement, this connector plays a significant role by linking various sensors and actuators. It allows for the monitoring of oil pressure and temperature, enabling the system to make real-time adjustments. This ensures optimal lubrication conditions are maintained throughout the engine’s operation, contributing to its longevity and efficiency.

Conclusion

The Cummins 5419193 Electrical Connector is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient operation of various engine systems. Its robust design, compatibility with specific Cummins engines, and role in maintaining optimal electrical connections contribute to the overall performance and safety of the vehicle. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this connector in commercial truck applications.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023

↩ -

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.