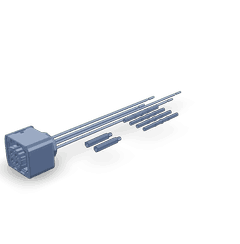

5299780

Electrical Repair Connector

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5299780 Electrical Repair Connector is a specialized component designed for the maintenance and repair of electrical systems in commercial trucks. Its purpose is to facilitate the restoration and upkeep of electrical connections, ensuring the reliable operation of the vehicle’s electrical systems. This connector plays a significant role in maintaining the functionality and safety of commercial trucks, contributing to their overall performance and longevity 1.

Basic Concepts of Electrical Repair Connectors

Electrical repair connectors are devices used to repair and maintain electrical connections within a vehicle’s electrical system. They serve to restore conductivity and integrity to damaged or worn-out electrical wires and terminals. These connectors are essential for ensuring that electrical signals and power are transmitted efficiently throughout the vehicle, supporting various systems such as lighting, engine management, and communication networks 2.

Purpose of the Cummins 5299780 Electrical Repair Connector

The Cummins 5299780 Electrical Repair Connector is specifically designed to address issues within the electrical systems of commercial trucks. It aids in the repair and maintenance of electrical connections by providing a secure and reliable means to reconnect or replace damaged sections of wiring. This connector ensures that electrical systems operate correctly, minimizing downtime and enhancing the safety and performance of the truck 3.

Key Features

The Cummins 5299780 Electrical Repair Connector boasts several key features that enhance its functionality and durability. These include a robust design that withstands the harsh conditions typical of commercial truck environments, high-quality materials that ensure long-lasting performance, and unique characteristics such as weather-resistant coatings and corrosion-resistant terminals. These features contribute to the connector’s reliability and ease of use during repairs.

Benefits

The advantages of using the Cummins 5299780 Electrical Repair Connector include improved reliability of electrical connections, ease of installation and use, and potential cost savings for fleet operators. By ensuring secure and durable connections, this connector helps prevent electrical failures, reducing the need for frequent repairs and maintenance. Its design also simplifies the repair process, allowing for quicker turnaround times and minimizing vehicle downtime.

Installation Process

Installing the Cummins 5299780 Electrical Repair Connector involves several steps to ensure a secure and effective connection. The process includes preparing the damaged wire by stripping and cleaning it, inserting it into the connector, and securing it in place. Tools such as wire strippers and crimping tools may be required, and safety precautions such as wearing protective gloves and ensuring the electrical system is de-energized should be observed to prevent accidents.

Troubleshooting Common Issues

Common issues with electrical repair connectors may include poor connections, corrosion, or damage to the connector itself. Troubleshooting steps involve inspecting the connector for signs of wear or damage, ensuring the wire is properly inserted and secured, and cleaning any corrosion from the terminals. If issues persist, replacing the connector may be necessary to restore proper function.

Maintenance Tips

Regular maintenance of the Cummins 5299780 Electrical Repair Connector is vital for ensuring its longevity and optimal performance. Maintenance tips include periodic inspection for signs of wear or damage, cleaning the connector and terminals to remove any dirt or corrosion, and replacing the connector if it shows signs of significant wear or failure. Adhering to these maintenance practices helps ensure the reliability of the electrical system.

Safety Considerations

When working with electrical repair connectors, it is important to adhere to safety protocols to prevent accidents and ensure personal safety. This includes ensuring the electrical system is de-energized before beginning any work, wearing appropriate protective gear such as gloves and safety glasses, and following manufacturer guidelines for installation and maintenance. These safety measures help protect both the technician and the vehicle from potential hazards.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a trusted partner for fleet operators and maintenance professionals.

Conclusion

The Cummins 5299780 Electrical Repair Connector is an essential component for maintaining the electrical systems of commercial trucks. Its robust design, key features, and ease of installation contribute to the reliability and performance of these vehicles. Regular maintenance and adherence to safety protocols are crucial for ensuring the longevity and optimal function of this Cummins part. By understanding and utilizing the 5299780 Electrical Repair Connector effectively, fleet operators can enhance the safety, performance, and cost-efficiency of their commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.