5299164

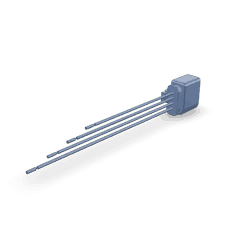

Electrical Repair Connector

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5299164 Electrical Repair Connector, manufactured by Cummins, is a specialized component designed for use in commercial truck maintenance. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of commercial vehicles. This part is significant in the realm of truck maintenance due to its role in facilitating repairs and ensuring the electrical systems of commercial trucks operate smoothly.

Basic Concepts of Electrical Repair Connectors

Electrical repair connectors are components used to join or repair electrical circuits within a vehicle. They play a role in maintaining the integrity of the vehicle’s electrical system by providing a secure and reliable connection point. These connectors facilitate the repair and maintenance of electrical systems by allowing technicians to easily connect and disconnect wires without causing damage to the system. This is particularly important in commercial trucks, where electrical systems are complex and critical to the vehicle’s operation 1.

Purpose of the 5299164 Electrical Repair Connector

This Cummins part is designed to play a specific role in the operation and maintenance of commercial trucks. It aids in diagnosing and repairing electrical issues by providing a reliable connection point that can be easily accessed and manipulated. This connector is integral to the process of identifying faults within the electrical system, as it allows for the isolation of specific circuits for testing and repair. Its design ensures that repairs can be made quickly and efficiently, minimizing downtime for commercial trucks 2.

Key Features

The 5299164 boasts several primary features that enhance its functionality and durability. Its design incorporates materials that are resistant to corrosion and wear, ensuring longevity even in the demanding environments typical of commercial truck operations. The connector is engineered to provide a secure connection, reducing the risk of electrical faults due to loose or damaged connections. Additionally, it features a robust construction that can withstand the vibrations and stresses encountered in truck operations.

Benefits

Using this part offers several advantages. It contributes to improved safety by ensuring that electrical connections are secure and reliable, reducing the risk of electrical faults that could lead to accidents. The connector also enhances the reliability of electrical system repairs, ensuring that trucks return to service quickly and with confidence. Furthermore, it improves efficiency in repairs by simplifying the process of connecting and disconnecting electrical circuits.

Installation and Usage

Proper installation of the 5299164 involves several steps. First, the area where the connector will be installed should be cleaned and prepared. The connector is then positioned over the wires to be joined, and the locking mechanism is engaged to secure the connection. Tools required for installation may include wire strippers, a crimping tool, and a multimeter for testing the connection. It is important to follow the manufacturer’s instructions closely to ensure a secure and reliable connection.

Troubleshooting and Maintenance

Common issues with electrical connectors in commercial trucks can include loose connections, corrosion, and damage from wear and tear. Regular inspection and maintenance of the 5299164 can help prevent these issues. Maintenance practices should include cleaning the connector and its surrounding area, checking for signs of wear or damage, and ensuring that the locking mechanism is functioning correctly. Any issues identified during maintenance should be addressed promptly to ensure the continued reliability of the electrical system.

Safety Considerations

When working with electrical systems and connectors in commercial trucks, it is important to observe several safety practices. These include ensuring that the vehicle’s battery is disconnected before beginning any work on the electrical system, using insulated tools to prevent electrical shocks, and wearing appropriate personal protective equipment. It is also crucial to follow all manufacturer instructions and safety guidelines when installing or repairing electrical connectors.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and components that are designed to meet the demanding requirements of commercial vehicles, ensuring efficiency, performance, and durability 3.

Conclusion

The 5299164 Electrical Repair Connector is a vital component in the maintenance and repair of commercial truck electrical systems. Its design and features ensure reliable and efficient repairs, contributing to the overall safety and performance of commercial vehicles. Proper installation, maintenance, and adherence to safety practices are essential to maximize the benefits of this Cummins part.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.