This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

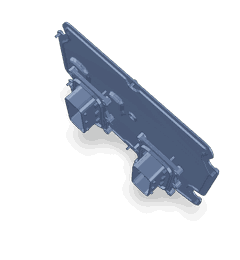

The Cummins 5290174 Electronic Control Module (ECM) is a sophisticated component designed to manage and optimize the operation of commercial trucks. This ECM is integral to the truck’s electronic system, ensuring efficient engine performance, emissions control, and overall vehicle functionality.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that plays a central role in a vehicle’s electronic system. It processes data from various sensors and actuators to manage engine and vehicle operations. The ECM continuously monitors and adjusts parameters such as fuel injection, ignition timing, and emissions control to ensure optimal performance and compliance with regulatory standards 1.

Role of the 5290174 ECM in Truck Operation

The 5290174 ECM is specifically designed to perform several key functions in a truck. It manages engine operations by controlling fuel injection and ignition timing, which are critical for efficient combustion. Additionally, the ECM plays a role in emissions control by regulating exhaust gases and ensuring that the truck meets environmental standards. It also integrates with other vehicle systems, such as the transmission and braking system, to provide a cohesive driving experience 2.

Key Features of the 5290174 ECM

The 5290174 ECM boasts several primary features that enhance its functionality. It has robust processing capabilities, allowing it to handle complex calculations and data processing in real-time. The ECM also includes substantial memory storage for logging diagnostic data and storing software updates. Furthermore, it integrates with various sensors throughout the vehicle, providing accurate and timely data for decision-making. The ECM utilizes advanced communication protocols to interact with other electronic systems within the truck 3.

Benefits of Using the 5290174 ECM

The advantages of using the 5290174 ECM are numerous. It contributes to improved engine performance by optimizing fuel injection and ignition timing. This optimization leads to enhanced fuel efficiency, reducing operational costs for fleet managers. Additionally, the ECM helps in reducing emissions, ensuring that the truck complies with environmental regulations. Its reliable operation increases the overall dependability of the vehicle, minimizing downtime and maintenance costs.

Troubleshooting the 5290174 ECM

Identifying common issues with the 5290174 ECM involves monitoring diagnostic trouble codes (DTCs) and performing systematic checks. Diagnostic procedures may include using specialized software to read ECM data, checking electrical connections, and verifying sensor inputs. Potential solutions range from software updates to replacing faulty sensors or the ECM itself, depending on the issue identified.

Maintenance Tips for the 5290174 ECM

Regular maintenance practices are vital for ensuring the longevity and efficiency of the 5290174 ECM. This includes keeping the ECM’s software up to date with the latest releases from Cummins. Sensor checks should be performed routinely to ensure accurate data collection. Protecting the ECM from environmental factors such as moisture and extreme temperatures is also important. This can be achieved by ensuring proper sealing and using environmental enclosures if necessary.

Integration with Other Systems

The 5290174 ECM interacts with various other truck systems to provide a seamless driving experience. It communicates with the transmission to optimize gear shifting based on driving conditions. The ECM also works with the braking system to enhance safety features such as anti-lock braking (ABS). Additionally, it provides data to driver information displays, allowing operators to monitor vehicle performance and diagnostic information in real-time.

Upgradability and Future-Proofing

The 5290174 ECM is designed with upgradability in mind. Software updates can be installed to adapt to new regulatory requirements and improve functionality. In some cases, hardware modifications may also be possible to enhance performance or add new features. This flexibility ensures that the ECM remains relevant and effective in the face of technological advancements and changing regulations.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. Founded in 1919, the company has a long history of innovation and commitment to quality. Cummins offers a wide range of products, including engines, filtration systems, and power generation equipment. The company is dedicated to advancing technology in the diesel engine market and providing solutions that meet the evolving needs of its customers.

Compatibility with ISB Engines

The 5290174 ECM is specifically engineered to fit with the ISB engines produced by Chrysler. The ISB (Intelligent Systems for Better) engine series is known for its robust design and efficiency, making it a popular choice in various applications, including heavy-duty trucks and industrial machinery.

Integration with Cummins Engines

In addition to Chrysler’s ISB engines, the 5290174 ECM is also compatible with certain Cummins engines. Cummins, a renowned manufacturer of diesel engines, utilizes this ECM to ensure optimal performance and reliability across its engine lineup. The seamless integration of this ECM with Cummins engines highlights its versatility and effectiveness in managing engine operations.

Grouping of Compatible Engines

The 5290174 ECM is designed to work with a range of engines, including:

- Chrysler ISB Engines

- Cummins Engines

This ECM’s compatibility with both Chrysler and Cummins engines underscores its importance in the automotive and industrial sectors. Its ability to interface with multiple engine types ensures that it can be a reliable choice for various applications, enhancing engine performance and efficiency.

Role of 5290174 ECM in Engine Systems

The 5290174 ECM is integral to the operation of modern engine systems, serving as the brain that orchestrates various functions to ensure optimal performance and efficiency.

Integration with Engine Control Module (ECM)

The 5290174 ECM works in tandem with the Engine Control Module to manage the engine’s operations. It processes data from various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. By analyzing this data, the ECM adjusts fuel injection timing, ignition timing, and other parameters to maintain engine performance under varying conditions.

Coordination with Electronic Service Calibration

Electronic Service Calibration (ESC) is another component where the 5290174 ECM plays a significant role. The ESC system relies on the ECM to store calibration data that fine-tunes engine performance. When maintenance or upgrades are performed, the ECM can be recalibrated to adapt to new components or changes in the engine system, ensuring that the engine continues to operate efficiently.

Sensor Data Management

The 5290174 ECM is responsible for collecting and interpreting data from a multitude of sensors distributed throughout the engine system. This includes but is not limited to, the throttle position sensor, engine speed sensor, and coolant temperature sensor. By continuously monitoring this data, the ECM can make real-time adjustments to engine parameters, enhancing both performance and fuel economy.

Actuator Control

In addition to sensor data management, the 5290174 ECM controls various actuators within the engine system. This includes the fuel injectors, idle air control valve, and variable valve timing solenoids. By precisely controlling these components, the ECM ensures that the engine operates smoothly and efficiently across a wide range of operating conditions.

Emission Control

The 5290174 ECM also plays a role in emission control systems. It monitors the operation of the Exhaust Gas Recirculation (EGR) valve and the catalytic converter, making adjustments to reduce harmful emissions. This not only helps the engine meet environmental regulations but also contributes to overall engine efficiency.

Fault Detection and Reporting

One of the 5290174 ECM’s essential functions is fault detection and reporting. It continuously monitors the engine system for any irregularities or malfunctions. When an issue is detected, the ECM stores a Diagnostic Trouble Code (DTC) and may illuminate the Check Engine Light (CEL) to alert the operator. This allows for timely maintenance and repairs, preventing more severe engine damage.

Conclusion

In summary, the 5290174 ECM is a multifaceted component that integrates with various engine systems to ensure optimal performance, efficiency, and compliance with emission standards. Its ability to adapt and respond to changing conditions makes it an indispensable part of modern engine technology.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.