This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

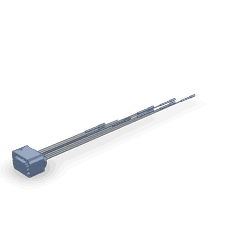

The Cummins 4919354 Electrical Repair Connector is a specialized component designed for use in commercial truck maintenance and operation. This connector plays a significant role in ensuring the integrity and functionality of electrical systems within these vehicles. Its purpose is to facilitate efficient repairs and maintenance, thereby contributing to the overall reliability and performance of commercial trucks.

Basic Concepts of Electrical Repair Connectors

Electrical repair connectors are components used to join or repair electrical circuits. They serve as intermediaries that ensure a secure and reliable connection between different parts of an electrical system. In the context of commercial trucks, these connectors are vital for maintaining the functionality of various electrical components, including lighting, sensors, and control systems. They simplify the process of repairing and maintaining electrical systems by providing a standardized method for connecting and disconnecting wires 1.

Purpose of the Cummins 4919354 Electrical Repair Connector

This Cummins part is specifically designed to address the needs of commercial truck electrical systems. It plays a role in repairing and maintaining these systems by providing a reliable connection point for electrical wires. This connector is applied in scenarios where existing connections need to be repaired or replaced, ensuring that the electrical system continues to operate efficiently. Its design allows for easy integration into existing systems, minimizing downtime during repairs 2.

Key Features

The 4919354 Electrical Repair Connector boasts several key features that enhance its functionality and durability. Its design incorporates high-quality materials that are resistant to corrosion and wear, ensuring long-lasting performance. The connector offers various connectivity options, allowing it to adapt to different electrical systems. Additionally, it features a robust construction that can withstand the vibrations and harsh conditions typical of commercial truck environments 3.

Benefits

Using this part offers several benefits. It contributes to the improved reliability of electrical connections, reducing the likelihood of failures and malfunctions. The connector’s design facilitates ease of installation, allowing for quick repairs and maintenance. Furthermore, its durability and reliability can lead to potential cost savings in maintenance and repair operations, as it reduces the frequency of required interventions 4.

Installation and Usage

Proper installation of the 4919354 Electrical Repair Connector involves several steps. First, ensure that the electrical system is de-energized to prevent any risk of electrical shock. Next, prepare the wires by stripping the insulation and cleaning the ends. Insert the prepared wires into the connector, ensuring a secure fit. Finally, use the appropriate tools to crimp or secure the connector in place, following the manufacturer’s guidelines for optimal performance.

Troubleshooting and Maintenance

To troubleshoot common issues related to electrical connectors in commercial trucks, begin by inspecting the connections for signs of corrosion, wear, or damage. Ensure that all connections are secure and that there are no loose wires. Regular maintenance involves cleaning the connectors and inspecting them for any signs of degradation. Applying a corrosion-resistant compound can help prolong the life of the connectors and ensure optimal performance.

Safety Considerations

When working with electrical systems and connectors in commercial trucks, it is important to observe several safety considerations. Always ensure that the electrical system is de-energized before beginning any work to prevent electrical shock. Use insulated tools to avoid accidental contact with live wires. Additionally, follow proper handling and installation procedures to ensure the safety and reliability of the electrical connections.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range and commitment to innovation ensure that its components, like the 4919354 Electrical Repair Connector, meet the high standards required for commercial truck applications.

Conclusion

The Cummins 4919354 Electrical Repair Connector is a vital component in the maintenance and operation of commercial trucks. Its design and features contribute to the reliability and efficiency of electrical systems, offering benefits such as ease of installation, durability, and cost savings in maintenance. Proper installation, regular maintenance, and adherence to safety considerations are essential for maximizing the performance and longevity of this connector.

-

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.