4918064

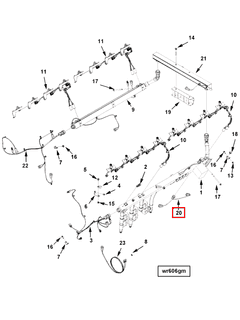

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #4918064) by Cummins is a vital component in the realm of heavy-duty trucks. This wiring harness is integral to the electronic systems of these vehicles, ensuring seamless communication and operation among various electronic components. Manufactured by Cummins, a renowned name in the automotive industry, this wiring harness exemplifies the blend of innovation and reliability that Cummins is known for 1.

Basic Concepts

Electronic Control Module Wiring Harnesses serve as the backbone of a vehicle’s electronic system. They facilitate the communication between the Electronic Control Module (ECM) and other electronic components within the truck. This communication is crucial for the operation of various systems, including engine management, transmission control, and diagnostic functions. The wiring harness acts as a conduit, ensuring that signals and power are efficiently transmitted between components 2.

Purpose and Functionality

The 4918064 Electronic Control Module Wiring Harness plays a significant role in the operation of a truck. It is designed to connect various electronic components, enabling them to communicate and function in unison. This harness is responsible for transmitting data and power to and from the ECM, ensuring that all electronic systems operate harmoniously. Its role is pivotal in maintaining the truck’s performance and efficiency 3.

Key Features

The 4918064 Electronic Control Module Wiring Harness is characterized by its robust design and high-quality construction materials. It is engineered to withstand the demanding conditions of heavy-duty truck environments. The harness features durable connectors and insulated wires, which enhance its performance and reliability. Additionally, its design allows for easy installation and maintenance, making it a practical choice for truck operators and technicians 4.

Benefits

The implementation of the 4918064 Electronic Control Module Wiring Harness in a truck’s system offers several benefits. It contributes to improved engine performance by ensuring efficient communication between the ECM and other components. This results in optimized engine operation and better overall performance. Furthermore, the harness aids in enhancing fuel efficiency by facilitating precise control over engine functions. Its reliable operation also contributes to the increased reliability of the truck’s electronic systems 5.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the 4918064 Electronic Control Module Wiring Harness, regular maintenance and troubleshooting are recommended. Inspecting the harness for any signs of wear, damage, or corrosion is crucial. Addressing these issues promptly can prevent potential malfunctions and ensure the continued efficient operation of the truck’s electronic systems. Additionally, following manufacturer guidelines for maintenance and repair can help in preserving the harness’s integrity and performance 6.

Cummins Overview

Cummins, the manufacturer of the 4918064 Electronic Control Module Wiring Harness, has a rich history in the automotive industry. Known for its commitment to quality and innovation, Cummins has established a strong reputation for producing reliable and high-performance automotive components. The company’s dedication to excellence is reflected in its products, including the 4918064 wiring harness, which embodies Cummins’ standards of quality and durability 7.

Compatibility with Cummins Engines

The ECM Wiring Harness is compatible with several Cummins engine models, including:

-

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK38 CM2350 K108

-

QSK50 Series

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

-

QSK60 Series

- QSK60 CM500

- QSK60 CM850 MCRS

Functionality and Importance

The ECM Wiring Harness plays a pivotal role in the engine’s electronic control system. It ensures that the ECM can receive real-time data from various sensors, such as temperature, pressure, and position sensors. This data is crucial for the ECM to make informed decisions about fuel injection, ignition timing, and other critical engine parameters.

The harness also connects the ECM to actuators and control modules, enabling the ECM to execute commands that adjust engine performance based on the data received. This seamless communication is essential for maintaining engine efficiency, reducing emissions, and ensuring reliable operation 8.

Installation and Maintenance

Proper installation of the ECM Wiring Harness is vital to ensure that all connections are secure and that there are no disruptions in the electrical signals. Regular maintenance checks should be performed to inspect for any signs of wear, corrosion, or damage to the wiring harness. Any issues detected should be addressed promptly to prevent potential engine malfunctions 9.

Conclusion

The ECM Wiring Harness (part 4918064) is an integral part of the electronic control system in Cummins engines. Its role in facilitating communication between the ECM and other components is essential for maintaining optimal engine performance and reliability. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this critical component.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.