This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4914076 Transducer is a specialized component designed for use in commercial truck operations. Its purpose is to convert one form of energy into another, facilitating the monitoring and regulation of various systems within the truck. This Cummins part plays a significant role in ensuring the efficient and reliable operation of commercial trucks, contributing to overall performance and safety.

Basic Concepts of Transducers

A transducer is a device that converts one type of energy into another. In automotive systems, transducers are commonly used to convert physical quantities such as pressure, temperature, or motion into electrical signals. These signals can then be interpreted by the vehicle’s electronic control units (ECUs) to make adjustments and ensure optimal performance. Transducers are integral to modern automotive systems, providing real-time data that enhances vehicle operation and diagnostics 1.

Purpose of the 4914076 Transducer

The Cummins 4914076 Transducer is specifically designed to monitor and regulate certain parameters within a commercial truck’s system. It plays a role in converting physical measurements into electrical signals that the truck’s ECU can use to make necessary adjustments. This ensures that the truck operates within safe and efficient parameters, contributing to both performance and longevity of the vehicle.

Key Features

The Cummins 4914076 Transducer is engineered with precision to meet the demanding requirements of commercial truck applications. Its design incorporates high-quality materials to ensure durability and reliability in various operating conditions. The transducer is equipped with advanced technological specifications that allow for accurate and consistent performance. These features include robust construction, precise calibration, and compatibility with a range of truck systems.

Benefits of Using the 4914076 Transducer

Incorporating the Cummins 4914076 Transducer into truck systems offers several advantages. It enhances the overall performance of the truck by providing accurate and timely data to the ECU. This leads to improved efficiency, as the truck can operate more smoothly and with fewer interruptions. Additionally, the transducer contributes to the reliability of the truck, reducing the likelihood of system failures and extending the vehicle’s operational life 2.

Installation and Integration

Installing the Cummins 4914076 Transducer involves integrating it into the truck’s existing systems. This process may require certain preparations or modifications to ensure compatibility and optimal performance. Proper installation is crucial to ensure that the transducer functions correctly and provides accurate data to the ECU. Detailed guidelines and procedures are available to assist with this process, ensuring a seamless integration.

Troubleshooting and Maintenance

Like any component, the Cummins 4914076 Transducer may encounter issues over time. Common problems can include signal inaccuracies, physical damage, or electrical faults. Troubleshooting these issues involves checking the transducer’s connections, inspecting for physical damage, and verifying the accuracy of the signals it produces. Regular maintenance practices, such as cleaning and calibration, can help ensure the longevity and optimal performance of the transducer.

Performance Monitoring

Monitoring the performance of the Cummins 4914076 Transducer is vital to maintaining the truck’s efficiency and reliability. This can be achieved through the use of diagnostic tools that allow mechanics or fleet operators to check the transducer’s output and ensure it is within specified parameters. Regular checks and inspections can help identify potential issues before they become significant problems, allowing for timely interventions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry. The company’s product range includes components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Transducer 4914076 Compatibility with Engine Models

The Cummins Transducer part number 4914076 is designed to integrate seamlessly with several engine models, ensuring optimal performance and reliability. This transducer is engineered to provide accurate data readings, which are crucial for the efficient operation of the engines it supports.

K19 and K38 Engines

The K19 and K38 engines benefit significantly from the precise data provided by the 4914076 transducer. These engines, known for their robust construction and high performance, require accurate monitoring of various parameters to maintain their operational efficiency. The transducer’s compatibility with these engines ensures that critical data is accurately captured and transmitted, facilitating better engine management and diagnostics.

K50 Engine

The K50 engine, another high-performance model, also integrates the 4914076 transducer effectively. This engine, designed for demanding applications, relies on the transducer to deliver real-time data that aids in maintaining optimal performance levels. The transducer’s design ensures it fits perfectly within the engine’s architecture, providing reliable and consistent data readings.

N14 MECHANICAL Engine

The N14 MECHANICAL engine, a staple in heavy-duty applications, is another beneficiary of the 4914076 transducer. This engine, known for its durability and power, requires precise monitoring to ensure it operates at peak efficiency. The transducer’s compatibility with the N14 MECHANICAL engine ensures that it can withstand the rigors of heavy-duty use while providing accurate data readings. This compatibility is crucial for maintaining the engine’s performance and longevity in demanding environments.

Role of Part 4914076 Transducer in Engine Systems

The 4914076 Transducer is an essential component that interfaces with various engine systems to ensure accurate data transmission and system functionality.

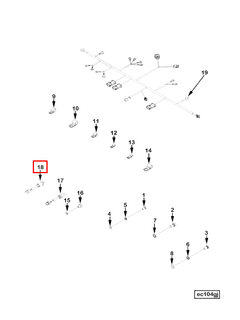

Integration with the Harness and Wiring

The transducer is connected to the engine’s wiring harness, which serves as the primary pathway for electrical signals. This connection allows the transducer to receive input signals from the engine and convert them into readable data. The wiring ensures that the transducer can communicate effectively with other engine components, facilitating real-time monitoring and control.

Interaction with the Panel

The data processed by the 4914076 Transducer is often displayed on the engine instrument panel. This panel provides operators with vital information about engine performance, such as pressure, temperature, and other critical metrics. The transducer ensures that the data presented on the panel is accurate and up-to-date, allowing for informed decision-making during engine operation.

Contribution to Engine Instruments

Engine instruments rely on precise data to function correctly. The 4914076 Transducer plays a significant role in this by converting physical parameters into electrical signals that these instruments can interpret. This ensures that gauges and displays provide accurate readings, which are essential for maintaining engine health and performance.

Conclusion

In summary, the 4914076 Transducer is a key component that enhances the functionality and reliability of engine systems by ensuring accurate data transmission and integration with essential engine components. Its role in converting physical measurements into electrical signals allows for real-time monitoring and control, contributing to the overall performance and safety of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.