This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

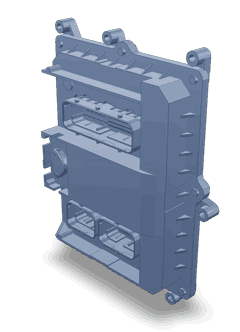

The Cummins 4898111 Electronic Control Module (ECM) is a sophisticated component designed to enhance the operation of commercial trucks. Its purpose is to manage and regulate various engine functions, ensuring optimal performance and efficiency. The significance of the 4898111 ECM lies in its ability to integrate advanced technology with practical truck operations, contributing to improved fuel efficiency, enhanced engine performance, and increased reliability.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that plays a central role in the operation of modern vehicle systems. It functions by receiving input from various sensors throughout the vehicle and processing this data to control engine functions. The ECM’s role in truck operations includes managing fuel injection, ignition timing, and emissions control, among other functions. The integration of ECMs has revolutionized truck operations by providing precise control and monitoring capabilities, leading to more efficient and reliable performance 1.

Purpose of the 4898111 Electronic Control Module

The 4898111 ECM is specifically designed to manage and regulate various engine functions in commercial trucks. It oversees fuel injection, ignition timing, and emissions control, ensuring that the engine operates within optimal parameters. By continuously monitoring and adjusting these functions, the ECM helps maintain engine performance and efficiency. Its role is vital in ensuring that the truck operates smoothly and reliably under various conditions.

Key Features

The 4898111 ECM boasts several key features that contribute to its effectiveness. Its design incorporates advanced technology and high-quality build materials, ensuring durability and reliability. Notable features include precise fuel management, adaptive control algorithms, and robust diagnostic capabilities. These features work together to enhance overall truck performance, providing drivers with a more efficient and dependable driving experience 2.

Benefits of Using the 4898111 ECM

The advantages provided by the 4898111 ECM are numerous. Improved fuel efficiency is one of the primary benefits, as the ECM optimizes fuel injection and combustion processes. Enhanced engine performance is another significant advantage, with the ECM ensuring that the engine operates at peak efficiency. Increased reliability is also a notable benefit, as the ECM’s precise control and monitoring capabilities help prevent issues and maintain consistent performance. These benefits have a direct impact on truck operations, leading to cost savings and improved productivity.

Installation and Integration

Proper installation and integration of the 4898111 ECM into a truck’s system are crucial for optimal performance. The process involves connecting the ECM to the truck’s sensor network and ensuring compatibility with the engine type. Detailed guidelines and steps should be followed to ensure a seamless integration. Compatibility with various truck models and engine types is an important consideration, as it ensures that the ECM can effectively manage the specific requirements of each application.

Troubleshooting and Maintenance

Common issues that may arise with the 4898111 ECM include sensor malfunctions, software glitches, and connectivity problems. Suggested troubleshooting steps involve checking sensor connections, updating software, and ensuring proper ECM placement. Maintenance tips to ensure the longevity and optimal performance of the ECM include regular inspections, keeping the ECM clean and dry, and following manufacturer-recommended service intervals. These practices help prevent issues and maintain the ECM’s effectiveness.

Diagnostic Capabilities

The 4898111 ECM is equipped with diagnostic features that monitor engine health, detect faults, and provide data for maintenance and repair. It continuously collects data from various sensors and uses this information to identify potential issues before they become critical. The ECM can store diagnostic trouble codes (DTCs) that indicate specific problems, allowing technicians to quickly diagnose and address issues. These diagnostic capabilities are invaluable for maintaining the ECM’s performance and ensuring the truck’s reliability.

Impact on Fuel Efficiency and Emissions

The 4898111 ECM contributes to improved fuel efficiency and reduced emissions through precise control of fuel injection and combustion processes. By optimizing these functions, the ECM ensures that the engine operates efficiently, leading to lower fuel consumption. Additionally, the ECM’s control over emissions systems helps reduce harmful emissions, contributing to a cleaner environment. The technologies and strategies employed by the ECM, such as adaptive control algorithms and real-time monitoring, are key to achieving these goals.

Cummins Corporation Overview

Cummins Corporation is a renowned manufacturer with a strong reputation in the industry for innovation and quality. Founded in 1919, Cummins has a long history of developing advanced engine components and systems. The company’s commitment to innovation is evident in its continuous investment in research and development, leading to the creation of cutting-edge products like the 4898111 ECM. Cummins’ dedication to quality ensures that its components meet the highest standards, providing reliable and efficient solutions for commercial truck operators.

Electronic Control Module (Part 4898111) by Cummins

The Electronic Control Module (ECM) part number 4898111, manufactured by Cummins, is a critical component in the operation of various engine models. This ECM is designed to manage and regulate the engine’s performance, ensuring optimal efficiency and reliability.

Integration with ISBE CM800 Engines

The ECM part 4898111 is specifically engineered to interface seamlessly with the ISBE CM800 engines. This integration is pivotal for the engine’s electronic management system, which controls fuel injection, ignition timing, and other vital functions. The ECM’s role in the ISBE CM800 ensures that the engine operates within its designed parameters, enhancing performance and longevity.

Compatibility with Other Cummins Engines

Beyond the ISBE CM800, the ECM part 4898111 is also compatible with a range of Cummins engines. This compatibility is achieved through standardized electronic interfaces and communication protocols, allowing the ECM to effectively manage various engine models. The ECM’s adaptability makes it a versatile component in the Cummins engine lineup, providing consistent performance across different engine types.

Grouping of Compatible Engines

The ECM part 4898111 is part of a broader group of Cummins engines that benefit from its advanced electronic control capabilities. This grouping includes engines that share similar design philosophies and electronic management systems, ensuring that the ECM can be easily integrated and function effectively across these models. The commonality in design allows for streamlined maintenance and repair processes, enhancing the overall reliability of the engine systems.

Role of Part 4898111 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM), identified by part number 4898111, is integral to the operation of modern engine systems. It serves as the brain of the engine, orchestrating a symphony of components to ensure optimal performance and efficiency.

Integration with Engine Control Components

-

Fuel Injection System: The ECM precisely controls the fuel injectors, determining the amount of fuel delivered to the engine based on real-time data from various sensors. This ensures efficient combustion and reduces emissions.

-

Ignition System: By managing the ignition timing, the ECM enhances engine performance and fuel economy. It receives input from sensors such as the crankshaft position sensor and adjusts the spark timing accordingly.

-

Exhaust Gas Recirculation (EGR) System: The ECM regulates the EGR valve to recirculate a portion of the exhaust gases back into the intake manifold. This reduces nitrogen oxides (NOx) emissions and improves engine efficiency.

-

Turbocharger Control: In turbocharged engines, the ECM monitors boost pressure and adjusts the wastegate or variable geometry turbine to maintain optimal turbo performance and prevent over-boosting.

-

Variable Valve Timing (VVT) System: The ECM controls the VVT system to optimize valve timing for different engine speeds and loads, enhancing performance and fuel efficiency.

-

Oxygen Sensors: The ECM uses data from oxygen sensors to adjust the air-fuel mixture, ensuring that the catalytic converter operates efficiently and emissions are minimized.

-

Throttle Position Sensor (TPS): By interpreting signals from the TPS, the ECM adjusts fuel delivery and ignition timing in response to driver input, ensuring smooth and responsive acceleration.

-

Coolant Temperature Sensor: The ECM uses coolant temperature data to adjust fuel delivery and ignition timing during cold starts, improving engine warm-up and reducing emissions.

-

Mass Air Flow (MAF) Sensor: The ECM relies on MAF sensor data to calculate the correct air-fuel ratio, ensuring efficient combustion under varying driving conditions.

-

Knock Sensor: The ECM monitors engine knock using knock sensors and adjusts ignition timing to prevent damage from detonation, ensuring smooth and reliable engine operation.

In summary, the ECM part 4898111 plays a pivotal role in coordinating these components to achieve optimal engine performance, efficiency, and emissions compliance.

Conclusion

The Cummins 4898111 Electronic Control Module is a critical component in the operation of commercial trucks, offering advanced control and monitoring capabilities that enhance engine performance, fuel efficiency, and reliability. Its integration with various engine systems ensures optimal operation under different conditions, making it a valuable asset for truck operators. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this ECM, contributing to cost savings and improved productivity in truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.