4401080

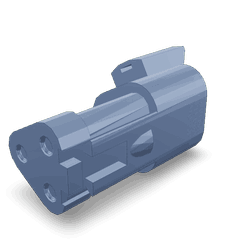

Electrical Connector

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4401080 Electrical Connector is a component manufactured by Cummins, a well-established name in the commercial truck industry. This connector is significant in commercial truck operations as it ensures reliable electrical connections within the vehicle’s systems.

Basic Concepts of Electrical Connectors

Electrical connectors are devices used to join electrical circuits, facilitating the transfer of electrical signals and power. In vehicles, they play a vital role in connecting various electrical components, ensuring that systems operate efficiently and effectively. These connectors are designed to withstand the rigors of vehicle operation, including vibrations, temperature fluctuations, and exposure to the elements 1.

Purpose of the 4401080 Electrical Connector

The 4401080 Electrical Connector is specifically designed to serve multiple functions within a truck’s electrical system. It is utilized in various truck systems to ensure secure and reliable electrical connections. This connector is integral to maintaining the functionality of critical systems, including lighting, sensors, and communication networks within the truck 2.

Key Features

The 4401080 Electrical Connector boasts several key features that enhance its functionality. Its design incorporates robust materials that provide durability and resistance to environmental factors. The connector is engineered to offer a secure fit, minimizing the risk of disconnection or poor contact. Additionally, it features protective coatings that guard against corrosion and moisture, ensuring long-term reliability 3.

Benefits

The advantages of using the 4401080 Electrical Connector include improved reliability in electrical connections, enhanced durability under demanding conditions, and increased efficiency in the transfer of electrical signals and power. These benefits contribute to the overall performance and longevity of the truck’s electrical systems.

Installation Process

Installing the 4401080 Electrical Connector requires careful attention to detail to ensure a secure connection. The process involves preparing the connection points, aligning the connector with the mating component, and securing it in place. Tools such as crimping tools may be required to ensure a proper fit. Following manufacturer guidelines and best practices is crucial to achieving a reliable connection.

Common Issues and Troubleshooting

Common problems with the 4401080 Electrical Connector may include loose connections, corrosion, or damage to the connector itself. Troubleshooting steps involve inspecting the connector for signs of wear or damage, cleaning any corrosion, and ensuring a secure fit. In some cases, replacing the connector may be necessary to restore proper functionality.

Maintenance Tips

Regular maintenance of the 4401080 Electrical Connector is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the connector to remove any dirt or corrosion, and ensuring that connections remain secure. Adhering to a maintenance schedule can help prevent issues and extend the life of the connector.

Safety Considerations

When working with the 4401080 Electrical Connector, it is important to observe safety guidelines to prevent accidents and ensure personal safety. This includes disconnecting the vehicle’s battery before working on electrical components, using insulated tools to avoid electrical shocks, and wearing appropriate personal protective equipment. Following these precautions can help ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and electrical components. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry.

Cummins Electrical Connector Part 4401080 Compatibility

The Cummins Electrical Connector part number 4401080 is designed to integrate seamlessly with a variety of Cummins engines, ensuring reliable electrical connections and optimal performance. This part is engineered to fit specific models within the Cummins engine lineup, providing a critical link in the engine’s electrical system.

K Series Engines

The K19, K38, and K50 engines are part of Cummins’ K Series, known for their robust design and versatility in various applications. The 4401080 connector is compatible with these models, ensuring that the electrical systems function correctly, which is vital for engine operation and diagnostics.

QSB6.7 and QST30 Engines

The QSB6.7 and QST30 engines are medium-duty diesel engines that are widely used in a range of applications, from agricultural machinery to construction equipment. The 4401080 connector is engineered to fit these engines, facilitating the necessary electrical connections for smooth operation.

QSC8.3, QSK19, QSK50, and QSK60 Engines

The QSC8.3, QSK19, QSK50, and QSK60 engines are part of Cummins’ heavy-duty lineup, designed for high-performance applications. The 4401080 connector is compatible with these engines, ensuring that the electrical systems are properly connected, which is crucial for maintaining engine efficiency and reliability.

QSM11 Engine

The QSM11 engine is a medium-duty diesel engine that is often used in industrial applications. The 4401080 connector is designed to fit this engine, ensuring that the electrical connections are secure and reliable.

QSC8.3 CM850(CM2850) and QSK19 CM2350 K144G

These engines, which include the QSC8.3 CM850(CM2850) and QSK19 CM2350 K144G, are equipped with the 4401080 connector to ensure that the electrical systems are properly integrated, providing the necessary connections for optimal engine performance.

QSK50 CM2150 MCRS and QSK60 CM850 MCRS

The QSK50 CM2150 MCRS and QSK60 CM850 MCRS engines are designed for heavy-duty applications and are compatible with the 4401080 connector. This ensures that the electrical systems are properly connected, which is essential for maintaining engine efficiency and reliability.

QST30 CM2350 T101

The QST30 CM2350 T101 engine is another model that is compatible with the 4401080 connector. This ensures that the electrical connections are secure and reliable, which is crucial for the engine’s performance.

Role of Part 4401080 Electrical Connector in Engine Systems

The 4401080 Electrical Connector is integral to the seamless operation of various engine systems by ensuring reliable electrical connections between components. This connector is specifically designed to interface with the Electronic Control Module (ECM) Wiring Harness, facilitating the transmission of data and power necessary for the ECM to monitor and regulate engine performance.

In the context of the ECM Wiring Harness, the 4401080 Electrical Connector allows for the secure attachment of sensor inputs and actuator outputs. This ensures that the ECM receives accurate data from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensor, and Manifold Absolute Pressure (MAP) sensor. Conversely, it enables the ECM to send precise signals to components like fuel injectors, ignition coils, and variable valve timing solenoids, thereby optimizing combustion efficiency and emissions control.

Additionally, the 4401080 Electrical Connector plays a significant role in the overall Harness system by providing a robust connection point for various subsystems. It ensures that power and ground connections are maintained under varying operating conditions, which is essential for the consistent performance of the engine.

Furthermore, when integrated with the Helm system, which often includes steering and control interfaces, the 4401080 Electrical Connector ensures that electrical signals for steering angle sensors and other control inputs are accurately transmitted. This is particularly important in modern vehicles where electronic power steering (EPS) systems rely on precise data to function correctly.

Conclusion

In summary, the 4401080 Electrical Connector is a foundational component that enhances the reliability and efficiency of engine systems by ensuring secure and consistent electrical connections across critical pathways.

-

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.