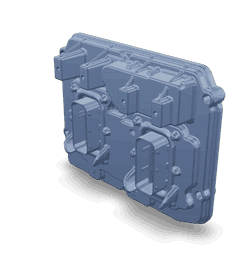

The 4384417 Electronic Control Module (ECM) by Cummins is a sophisticated component designed to manage and regulate various engine and vehicle functions in commercial trucks. Its purpose is to enhance the overall performance, efficiency, and reliability of the truck. The significance of this Cummins part lies in its ability to integrate seamlessly with other truck systems, providing a cohesive and optimized operation.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that plays a central role in the operation of modern vehicle systems. It functions by receiving input from various sensors throughout the vehicle, processing this data, and sending output signals to actuators to control different functions. In the context of truck operations, ECMs are integral to managing engine performance, fuel efficiency, and overall vehicle dynamics. They facilitate the integration of multiple systems, ensuring that all components work in harmony to achieve optimal performance 1.

Purpose of the 4384417 ECM

The 4384417 ECM is specifically designed to manage and regulate a range of engine and vehicle functions in commercial trucks. It oversees critical operations such as fuel injection, ignition timing, and emissions control. By continuously monitoring and adjusting these parameters, the ECM ensures that the engine operates efficiently and within specified parameters. Additionally, it plays a role in enhancing the truck’s drivability and responsiveness, contributing to a smoother and more reliable driving experience.

Key Features

The 4384417 ECM boasts several key features that contribute to its effectiveness and durability. Its design incorporates advanced microprocessors and robust circuitry, ensuring reliable performance under various operating conditions. The build quality is exceptional, with a focus on durability and resistance to environmental factors such as heat, vibration, and moisture. Technological advancements within the ECM include real-time data processing capabilities and enhanced communication protocols, which facilitate better integration with other truck systems 2.

Benefits of Using the 4384417 ECM

The advantages provided by the 4384417 ECM are numerous. It contributes to improved fuel efficiency by optimizing engine performance and reducing unnecessary fuel consumption. Enhanced engine performance is achieved through precise control of fuel injection and ignition timing. Increased reliability is another significant benefit, as the ECM’s robust design and advanced features help prevent malfunctions and ensure consistent operation. These benefits have a direct impact on truck operations and fleet management, leading to reduced maintenance costs and increased uptime.

Integration with Other Systems

The 4384417 ECM interacts with various other truck systems, including the engine, transmission, and braking systems. It communicates with these systems through established protocols and data exchange mechanisms, ensuring seamless operation. This integration allows for coordinated control of engine functions, transmission shifts, and braking performance, resulting in a more harmonious and efficient truck operation 3.

Diagnostic and Monitoring Capabilities

One of the notable features of the 4384417 ECM is its diagnostic capabilities. It continuously monitors engine health and can detect faults in real-time. When an issue is identified, the ECM generates diagnostic trouble codes, which can be read by technicians to pinpoint the problem. These capabilities aid in maintenance and troubleshooting, allowing for quicker resolution of issues and reduced downtime.

Programming and Updates

Programming the 4384417 ECM involves configuring the module to match the specific requirements of the truck it is installed in. Regular updates are important to ensure that the ECM continues to perform optimally. Updates can improve performance by incorporating the latest algorithms and addressing any identified issues. They also help maintain compatibility with other systems and ensure that the ECM remains up-to-date with the latest technological advancements.

Troubleshooting and Maintenance

Troubleshooting common issues with the 4384417 ECM can be facilitated by understanding its diagnostic features and communication protocols. Regular maintenance practices, such as keeping the ECM clean and free from corrosion, can help ensure optimal performance and longevity. Additionally, following manufacturer guidelines for updates and calibrations can prevent many potential issues.

Cummins: A Brief Overview

Cummins Inc. is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a long history of innovation and quality in manufacturing engines, powertrains, and other automotive components. The company’s commitment to advancing technology and maintaining high standards of quality is evident in its ECMs and other products. Cummins continues to lead the industry with its focus on reliability, performance, and customer satisfaction.

Electronic Control Module (ECM) Part 4384417 by Cummins

The Electronic Control Module (ECM) part 4384417, manufactured by Cummins, is a critical component in the operation of various engines. This ECM is designed to manage and control the engine’s performance by regulating fuel injection, ignition timing, and other vital functions.

Compatibility with ISB Engines

The ECM part 4384417 is specifically engineered to fit with the ISB engines produced by Chrysler. The ISB engines, known for their robust performance and reliability, benefit significantly from the precise control provided by this ECM. The integration of the ECM ensures optimal engine performance, efficiency, and longevity.

Integration Process

The integration of the ECM part 4384417 into the ISB engines involves several key steps:

- Installation: The ECM is securely mounted within the engine’s control area. This placement ensures that it can effectively communicate with the engine’s sensors and actuators.

- Wiring: The ECM is connected to the engine’s wiring harness. This connection allows the ECM to receive data from various sensors and send control signals to the engine’s components.

- Programming: The ECM is programmed to match the specific requirements of the ISB engine. This programming includes calibrations for fuel injection, ignition timing, and other performance parameters.

- Testing: After installation, the ECM undergoes rigorous testing to ensure it functions correctly and integrates seamlessly with the engine.

Benefits of Using Cummins ECM

Using the Cummins ECM part 4384417 offers several advantages:

- Enhanced Performance: The ECM ensures that the engine operates at peak efficiency, providing better power output and fuel economy.

- Improved Reliability: By precisely controlling engine functions, the ECM helps to prevent issues such as misfires and overheating.

- Ease of Maintenance: The ECM’s advanced diagnostics capabilities make it easier to identify and address potential problems before they become serious issues.

By integrating the Cummins ECM part 4384417 into the ISB engines, Chrysler ensures that these engines maintain their reputation for reliability and performance.

Role of Part 4384417 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM), identified by part number 4384417, is integral to the operation of modern engine systems. It acts as the central processing unit of the engine control system, interfacing with a variety of sensors and actuators to manage engine performance, emissions, and fuel efficiency.

Interaction with Sensors

The ECM continuously receives data from numerous sensors distributed throughout the engine system. Key sensors include:

- Mass Air Flow (MAF) Sensor: Provides information on the amount of air entering the engine, allowing the ECM to adjust fuel delivery accordingly.

- Oxygen (O2) Sensors: Monitor the oxygen content in the exhaust gases, enabling the ECM to fine-tune the air-fuel mixture for optimal combustion.

- Throttle Position Sensor (TPS): Indicates the position of the throttle, helping the ECM to determine the desired engine load and adjust fuel and ignition timing.

- Manifold Absolute Pressure (MAP) Sensor: Measures the pressure in the intake manifold, assisting the ECM in calculating the engine load and air density.

Control of Actuators

Based on the data from these sensors, the ECM controls various actuators to maintain engine performance and efficiency:

- Fuel Injectors: The ECM regulates the timing and duration of fuel injection to achieve the desired air-fuel ratio.

- Ignition System: It controls the spark timing to ensure precise ignition of the air-fuel mixture, optimizing combustion efficiency and power output.

- Exhaust Gas Recirculation (EGR) Valve: The ECM manages the EGR valve to recirculate a portion of the exhaust gases back into the intake, reducing nitrogen oxides (NOx) emissions.

- Variable Valve Timing (VVT) System: In engines equipped with VVT, the ECM adjusts the timing of the valve events to improve performance and fuel economy across different operating conditions.

Emission Control

The ECM plays a significant role in emission control by:

- Monitoring Catalyst Efficiency: Using data from oxygen sensors placed before and after the catalytic converter, the ECM assesses the converter’s efficiency and adjusts engine parameters to maintain optimal performance.

- Evaporative Emission Control System: The ECM controls the purge valve to manage the release of fuel vapors from the charcoal canister into the engine, ensuring they are burned rather than released into the atmosphere.

Integration with Other Systems

The ECM also communicates with other vehicle systems to enhance overall performance:

- Transmission Control Module (TCM): For vehicles with automatic transmissions, the ECM works in conjunction with the TCM to optimize gear shifting based on driving conditions and engine load.

- Anti-lock Braking System (ABS): In some vehicles, the ECM shares data with the ABS to modulate engine power during braking, improving stability and control.

Conclusion

In summary, the 4384417 Electronic Control Module is a sophisticated component that ensures the engine operates efficiently, meets emission standards, and delivers optimal performance under varying conditions. Its integration with various sensors and actuators, along with its communication with other vehicle systems, underscores its importance in modern engine management.

-

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Thorsten Boger, Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Bruce P. Minaker. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.