This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4384413 Electronic Control Module (ECM) is a sophisticated component designed to manage and optimize the operation of commercial trucks. Its purpose is to enhance the efficiency, performance, and reliability of the vehicle by controlling various engine functions and integrating with other truck systems. The significance of the 4384413 ECM lies in its ability to provide precise control over engine operations, ensuring optimal performance under a wide range of conditions.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that manages the functions of an engine by processing data from various sensors and executing control algorithms. In modern vehicle systems, the ECM plays a central role by receiving input from sensors, making decisions based on pre-programmed algorithms, and sending output signals to actuators to control engine functions. In heavy-duty trucks, ECMs are integrated to handle complex tasks such as fuel injection, ignition timing, and emissions control, ensuring the engine operates efficiently and meets regulatory standards 1.

Purpose of the 4384413 Electronic Control Module

The 4384413 ECM is specifically designed to manage the engine’s operations in commercial trucks. It oversees engine management by regulating fuel injection, ignition timing, and other critical parameters to ensure optimal performance. Additionally, the ECM plays a role in emissions control by monitoring and adjusting engine functions to minimize harmful emissions. Overall, the 4384413 ECM contributes to the truck’s performance by ensuring smooth operation, enhancing fuel efficiency, and maintaining compliance with emissions regulations.

Key Features

The primary features of the 4384413 ECM include advanced processing capabilities, substantial memory storage for data logging and software execution, integration with various sensors to gather real-time data, and robust communication protocols to interact with other vehicle systems. These features allow the ECM to make precise adjustments to engine operations, store diagnostic information, and communicate with other truck systems to ensure coordinated performance.

Benefits of Using the 4384413 ECM

Incorporating the 4384413 ECM into truck systems offers several advantages. It contributes to improved fuel efficiency by optimizing engine operations, enhances engine performance through precise control of critical parameters, reduces emissions by ensuring compliance with regulatory standards, and increases reliability by monitoring engine health and detecting potential issues before they become critical.

Integration with Other Systems

The 4384413 ECM interacts with various truck systems to ensure seamless operation. It communicates with the transmission to optimize gear shifting, works with the braking system to enhance safety and performance, and integrates with driver assistance technologies to provide a more intuitive and safe driving experience. This integration allows the ECM to coordinate with other systems, resulting in improved overall vehicle performance.

Diagnostic and Monitoring Capabilities

The 4384413 ECM is equipped with diagnostic features that enable it to monitor engine health, detect faults, and provide data for maintenance and repair. It continuously gathers data from sensors and uses this information to identify potential issues, allowing for proactive maintenance and reducing the likelihood of unexpected breakdowns. The ECM also stores diagnostic trouble codes that can be accessed by technicians for troubleshooting and repair.

Suggestions on Troubleshooting and Maintenance

Common issues with the 4384413 ECM may include software glitches, sensor malfunctions, or communication errors with other systems. Troubleshooting steps involve checking for diagnostic trouble codes, verifying sensor inputs, and ensuring proper communication with other systems. Maintenance practices include regular software updates, sensor calibration, and periodic inspections to ensure the ECM operates within specified parameters.

Firmware and Software Updates

Keeping the ECM’s firmware and software up to date is important for ensuring optimal performance and compatibility with the latest technologies. Procedures for updates typically involve downloading the latest software from the manufacturer, following specific instructions for installation, and verifying the update through diagnostic tools. Maintaining current software versions ensures the ECM operates efficiently and takes advantage of the latest improvements and features.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial vehicle industry for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines and technologies designed to meet the demanding requirements of commercial applications 2.

Compatibility with Cummins Engines

The Electronic Control Module (ECM) part number 4384413, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. Specifically, it is compatible with the X12 CM2350 X119B, X15 CM2350 X116B, and X15 CM2350 X123B engines.

For the X12 CM2350 X119B and X15 CM2350 X116B engines, the ECM part 4384413 is engineered to provide precise control over engine operations, ensuring optimal performance and efficiency. This ECM is capable of managing various engine functions, including fuel injection, ignition timing, and emissions control, by communicating with other engine components through a network of sensors and actuators.

Similarly, the ECM part 4384413 is also compatible with the X15 CM2350 X123B engine. This ECM ensures that the engine operates within its designed parameters, enhancing reliability and longevity. It is equipped with advanced diagnostic capabilities, allowing for real-time monitoring and troubleshooting of engine performance.

In all these engines, the ECM part 4384413 plays a role in maintaining the balance between performance and fuel efficiency, adapting to varying operational conditions to ensure the engine runs smoothly and efficiently.

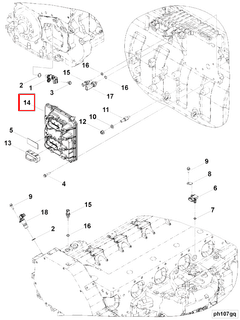

Role of Part 4384413 Electronic Control Module in Engine Systems

Part 4384413, the Electronic Control Module (ECM), is integral to the operation and management of various engine systems. It acts as the central processing unit for the engine, receiving data from numerous sensors and making real-time adjustments to optimize performance and efficiency.

Fuel Injection System

The ECM continuously monitors inputs from the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. Based on this data, it calculates the precise amount of fuel required and controls the fuel injectors to deliver the optimal air-fuel mixture. This ensures efficient combustion and reduces emissions.

Ignition System

In coordination with the Crankshaft Position (CKP) sensor and Camshaft Position (CMP) sensor, the ECM determines the exact timing for spark plug ignition. This precise timing is essential for maximizing power output and fuel efficiency while minimizing wear on engine components.

Emission Control System

The ECM plays a role in managing the emission control systems, including the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. By regulating the EGR valve, it reduces nitrogen oxides (NOx) emissions. Additionally, it monitors the catalytic converter’s efficiency through the use of downstream O2 sensors, ensuring that harmful emissions are minimized.

Idle Control System

Through the Idle Air Control (IAC) valve, the ECM maintains the engine’s idle speed within a specified range. It adjusts the airflow into the engine to compensate for changes in load, such as when the air conditioning compressor engages or when the steering is turned at low speeds.

Variable Valve Timing (VVT) System

In engines equipped with VVT, the ECM controls the timing of the camshaft(s) to optimize valve operation for different engine speeds and loads. This enhances performance, fuel economy, and emissions control by allowing the engine to operate more efficiently across a wider range of conditions.

Turbocharger Control

For turbocharged engines, the ECM manages the wastegate and boost pressure to ensure that the turbocharger operates within safe parameters. It adjusts the wastegate position to control boost pressure, preventing over-boosting which could lead to engine damage.

Transmission Control

In vehicles with automatic transmissions, the ECM works in conjunction with the Transmission Control Module (TCM) to manage shift points and torque converter lock-up. This ensures smooth and efficient transmission operation, enhancing overall vehicle performance.

Battery and Charging System

The ECM monitors the battery’s state of charge and the alternator’s output. It adjusts the alternator’s field current to maintain the battery at optimal charge levels, ensuring reliable starting and electrical system performance.

Coolant and Air Conditioning Systems

The ECM also interfaces with the engine’s coolant system and the vehicle’s air conditioning system. It controls the operation of the radiator fan and the air conditioning compressor to maintain optimal engine temperature and cabin comfort.

Conclusion

In summary, the 4384413 Electronic Control Module is a multifaceted component that ensures the engine operates efficiently, reliably, and within environmental regulations. Its role in managing various engine systems underscores its importance in modern automotive engineering.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.