This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

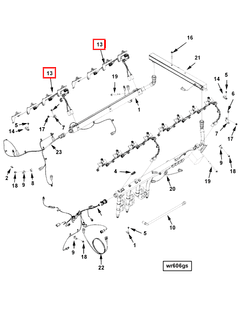

The 4382021 Electronic Control Module (ECM) Wiring Harness, manufactured by Cummins, is a vital component in the operation of commercial trucks. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation. This wiring harness is designed to facilitate the electrical connections necessary for the ECM to communicate with various systems within the truck, ensuring efficient and reliable operation.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires and connectors that link the ECM to other electronic components within the truck. It consists of insulated wires, connectors, terminals, and sometimes protective conduits. The harness functions by transmitting electrical signals and power between the ECM and other systems, such as the engine, transmission, and various sensors. This communication is essential for the ECM to monitor and control the truck’s performance, fuel efficiency, and emissions 1.

Role of the 4382021 Electronic Control Module Wiring Harness in Truck Operation

The 4382021 Wiring Harness plays a significant role in the overall operation of a commercial truck. It enables the ECM to receive data from sensors and send commands to actuators, ensuring that the engine, transmission, and other systems operate in harmony. The harness also supports the diagnostic capabilities of the ECM, allowing for the identification of issues and the implementation of corrective actions. Its interaction with other systems ensures that the truck operates efficiently and reliably 2.

Key Features of the 4382021 Wiring Harness

The 4382021 Wiring Harness is characterized by several key features that enhance its performance and durability. These include high-quality materials that resist wear and environmental factors, a robust design that ensures longevity, and precise engineering that allows for seamless integration with the truck’s electrical system. The harness is also designed to be flexible, accommodating the various configurations and requirements of different truck models 3.

Benefits of Using the 4382021 Wiring Harness

Utilizing the 4382021 Wiring Harness offers several benefits. It contributes to improved reliability by ensuring stable and consistent electrical connections. The harness also enhances the efficiency of the truck’s systems by facilitating quick and accurate data transmission. Additionally, its design allows for easier maintenance and troubleshooting, reducing downtime and repair costs.

Installation Considerations

Proper installation of the 4382021 Wiring Harness is crucial for its effective operation. It is important to follow manufacturer guidelines, ensuring that all connections are secure and that the harness is routed correctly to avoid damage from heat, friction, or moving parts. Careful attention should be paid to grounding points to ensure electrical stability. Common pitfalls include improper routing, insufficient securing of the harness, and neglecting to check for pre-existing damage.

Troubleshooting Common Issues

When issues arise with the 4382021 Wiring Harness, systematic troubleshooting is necessary. Begin by checking for visible damage to the harness or connectors. Use diagnostic tools to identify any communication errors between the ECM and other systems. Common issues may include loose connections, corroded terminals, or damaged wires. Addressing these problems promptly can prevent more significant issues and ensure the continued reliable operation of the truck.

Maintenance Tips

Regular maintenance of the 4382021 Wiring Harness is essential for its longevity and optimal performance. Inspect the harness periodically for signs of wear, corrosion, or damage. Clean connectors to ensure good electrical contact and protect the harness from environmental factors such as moisture and extreme temperatures. Following these maintenance practices can help prevent unexpected failures and extend the life of the wiring harness.

Safety Precautions

When working with the 4382021 Wiring Harness, it is important to observe several safety precautions. Ensure that the truck’s battery is disconnected before beginning any work to avoid the risk of electrical shock. Use appropriate personal protective equipment, such as insulated gloves and safety glasses. Handle the harness carefully to avoid damaging the wires or connectors. Adhering to these safety guidelines will help protect both the technician and the equipment.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a long-standing reputation for producing high-quality automotive components. Founded in 1919, the company has a history of innovation and excellence in the diesel engine and related technologies market. Cummins is committed to delivering reliable, efficient, and durable products, backed by comprehensive support and service. Their components, including the 4382021 Wiring Harness, are designed with precision and quality in mind, ensuring they meet the demanding requirements of commercial truck operations.

Cummins Electronic Control Module Wiring Harness (Part 4382021)

The Cummins Electronic Control Module Wiring Harness, identified by part number 4382021, is a critical component in the electrical system of several Cummins engines. This wiring harness is designed to ensure seamless communication and power distribution between the Electronic Control Module (ECM) and various engine sensors and actuators.

Application in Cummins Engines

QSK60 and CM850 Engines

The QSK60 and CM850 engines are part of Cummins’ heavy-duty diesel engine lineup, often used in industrial, marine, and power generation applications. The 4382021 wiring harness is integral to these engines, facilitating the transfer of electrical signals that are essential for the ECM to monitor and control engine performance. This harness ensures that the ECM can accurately read sensor data and send commands to the engine’s actuators, thereby maintaining optimal engine operation.

MCRS Engines

The MCRS (Modular Component Remanufacturing System) engines are another series where the 4382021 wiring harness plays a pivotal role. These engines are designed for flexibility and ease of remanufacturing, making them suitable for various applications, including construction and agricultural machinery. The wiring harness in these engines is crucial for maintaining the integrity of the ECM’s communication network, ensuring that the engine can adapt to different operational conditions and maintain peak efficiency.

Importance of the Wiring Harness

The 4382021 wiring harness is engineered to withstand the harsh environments in which these engines typically operate. It is designed to resist high temperatures, vibrations, and electrical interference, ensuring reliable performance over the engine’s lifespan. Proper installation and maintenance of this harness are essential to prevent electrical faults that could lead to engine downtime or performance issues.

By integrating the 4382021 wiring harness into the QSK60, CM850, and MCRS engines, Cummins ensures that these engines can operate with maximum efficiency and reliability, meeting the demands of their respective applications.

Conclusion

The Electronic Control Module (ECM) Wiring Harness, part 4382021, serves as the vital conduit for electrical signals and power within the engine system. This harness is meticulously designed to interface with various engine components, ensuring seamless communication and operation. It connects the ECM to the engine’s sensors, such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. These connections allow the ECM to receive real-time data on air intake, oxygen levels, and pressure conditions, enabling precise fuel injection and ignition timing adjustments.

The harness also links to the engine’s actuators, including the fuel injectors, throttle body, and ignition coils. This ensures that the ECM’s commands are accurately executed, optimizing engine performance and efficiency. Additionally, it interfaces with the vehicle’s onboard diagnostics system, facilitating error detection and reporting.

Furthermore, the ECM Wiring Harness integrates with the engine’s cooling system components, such as the coolant temperature sensor and the radiator fan control module. This integration allows the ECM to monitor and regulate engine temperature, preventing overheating and ensuring optimal operating conditions.

In summary, the ECM Wiring Harness, part 4382021, is integral to the engine system’s functionality, enabling the ECM to effectively manage and coordinate the operations of various engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.