This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

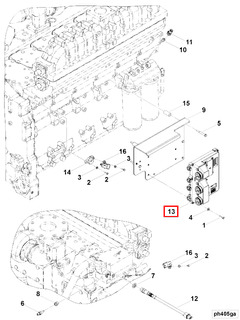

The 4364458 Electronic Control Module (ECM) manufactured by Cummins is a sophisticated component designed to enhance the operation of heavy-duty trucks. This ECM is integral to modern automotive technology, providing advanced control and monitoring capabilities that contribute to efficient and reliable truck performance.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that manages various vehicle systems by processing data from sensors and other inputs. It plays a role in vehicle systems by regulating functions such as engine performance, transmission shifts, and emissions control. The ECM interfaces with other components through a network of sensors and actuators, allowing it to make real-time adjustments based on driving conditions. The evolution of ECMs in the automotive industry has led to more efficient, powerful, and environmentally friendly vehicles 1.

Purpose of the 4364458 ECM in Truck Operations

The 4364458 ECM is specifically designed to manage the operation of heavy-duty trucks. It plays a role in engine performance by optimizing fuel injection, ignition timing, and air-fuel mixture. Additionally, it contributes to fuel efficiency by monitoring and adjusting these parameters to ensure the engine operates within optimal ranges. The ECM also plays a role in emission controls by regulating exhaust outputs and ensuring compliance with environmental standards 2.

Key Features of the 4364458 ECM

The 4364458 ECM boasts several primary features that enhance its functionality. It includes robust processing power to handle complex calculations and data processing in real-time. The ECM has a significant memory capacity, allowing it to store extensive data logs and diagnostic information. It integrates with various sensors throughout the truck, providing comprehensive monitoring capabilities. Additionally, it utilizes advanced communication protocols to interact seamlessly with other truck systems.

Benefits of Using the 4364458 ECM

Incorporating the 4364458 ECM into truck systems offers several advantages. It contributes to improved engine performance by ensuring optimal operation under varying conditions. The ECM enhances diagnostics through detailed error code generation and self-diagnostic routines, facilitating quicker issue identification and resolution. Furthermore, it increases reliability by continuously monitoring and adjusting system parameters to prevent malfunctions 3.

Integration with Other Systems

The 4364458 ECM interacts with other truck systems, including the transmission, braking system, and driver assistance technologies. It utilizes communication networks such as the Controller Area Network (CAN) bus to exchange data with these systems, ensuring coordinated operation and enhanced overall performance. This integration allows for seamless interaction between different components, leading to a more efficient and responsive truck.

Diagnostic Capabilities

The 4364458 ECM offers comprehensive diagnostic features. It generates error codes that indicate specific issues within the truck’s systems, aiding in quick identification of problems. The ECM performs self-diagnostic routines to check its own functionality and detect potential faults. It also logs data over time, providing valuable information for maintenance purposes and helping to predict future issues.

Troubleshooting Common Issues

Identifying and addressing common problems associated with the 4364458 ECM involves several steps. Begin by retrieving any stored error codes using diagnostic tools. These codes can point to specific issues, such as sensor malfunctions or communication errors. Follow recommended troubleshooting procedures, which may include checking wiring connections, testing sensors, and verifying software updates. Regular maintenance and periodic checks can help prevent many common issues.

Maintenance and Upkeep

To ensure optimal performance of the 4364458 ECM, regular maintenance is recommended. This includes keeping the software up to date to benefit from the latest improvements and bug fixes. Protecting the ECM from environmental factors such as moisture and extreme temperatures is also important. Periodic checks of the ECM and its connections can help identify potential issues before they become significant problems.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its innovative engine and component solutions. With a rich history of providing high-quality products, Cummins has established itself as a trusted name in the field. The company’s commitment to innovation and quality is evident in its diverse product range, which includes engines, filtration systems, and electronic controls designed to meet the demanding needs of heavy-duty applications.

Electronic Control Module 4364458 Compatibility with Cummins Engines

The Electronic Control Module (ECM) part number 4364458, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engine models. This ECM is a critical component in managing engine performance, ensuring optimal operation, and maintaining compatibility with advanced diagnostic systems.

G855 CM558 and GTA855 CM558 (CM2358) G101

The ECM 4364458 is compatible with the G855 CM558 and GTA855 CM558 (CM2358) G101 engines. These engines are part of Cummins’ high-performance lineup, often utilized in heavy-duty applications where reliability and power are paramount. The ECM ensures that these engines operate efficiently, providing the necessary control and monitoring functions to maintain peak performance.

GTA38 G CMEICS G116C

The ECM 4364458 also fits with the GTA38 G CMEICS G116C engine. This engine is known for its robust design and is typically used in applications requiring substantial power and durability. The ECM’s compatibility with this engine ensures that it can handle the specific demands of this model, providing precise control and diagnostics.

KTA19GC CM558

Lastly, the ECM 4364458 is compatible with the KTA19GC CM558 engine. This engine is another member of Cummins’ lineup, often used in industrial and marine applications. The ECM’s integration with this engine ensures that it can manage the engine’s performance effectively, providing the necessary electronic control and monitoring functions.

By ensuring compatibility with these engines, the ECM 4364458 from Cummins provides a reliable and efficient solution for managing engine performance across various applications.

Role of Part 4364458 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM) part 4364458 is integral to the operation of various engine systems. It interfaces with the Engine Control Module (ECM) to manage the engine’s performance by regulating fuel delivery, ignition timing, and emissions controls.

In conjunction with the Fuel Control Module, part 4364458 ensures precise fuel metering, which is essential for optimal combustion efficiency and power output. It communicates with sensors to adjust fuel injection rates in real-time, enhancing both performance and fuel economy.

The ECM also works in tandem with the Electronic Service Calibration Module to fine-tune engine parameters. This calibration ensures that the engine operates within specified limits, maintaining reliability and longevity.

Furthermore, the ECM’s role extends to emissions control systems, where it monitors and adjusts variables to meet environmental regulations. This includes managing the air-fuel ratio and controlling exhaust gas recirculation.

In summary, part 4364458 Electronic Control Module is a central component that coordinates various engine subsystems, ensuring efficient, reliable, and compliant engine operation 4.

Conclusion

The 4364458 ECM by Cummins is a critical component in the operation of heavy-duty trucks, offering advanced control and monitoring capabilities. Its integration with various engine systems ensures optimal performance, fuel efficiency, and compliance with environmental standards. Regular maintenance and proper troubleshooting are essential to maximize the benefits of this sophisticated component.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.