4354558

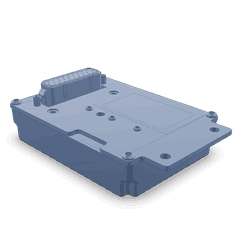

Electronic Control Module

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4354558 Electronic Control Module (ECM) by Cummins is a sophisticated component designed to enhance the operation of commercial trucks. This ECM plays a role in optimizing engine performance and efficiency, contributing to the overall effectiveness of truck operations.

Basic Concepts of Electronic Control Modules

An Electronic Control Module is a vital component within a truck’s engine management system. It functions by processing data from various sensors and actuators to manage engine operations. The ECM operates on basic principles of data acquisition, processing, and control signal generation, ensuring the engine runs efficiently and meets performance standards 1.

Role of the 4354558 ECM in Truck Operation

The 4354558 ECM performs several specific functions in truck operation. It controls engine parameters such as fuel injection timing, air-fuel ratio, and ignition timing. Additionally, it manages emissions by monitoring and adjusting engine operations to comply with environmental regulations. The ECM also optimizes performance by adapting to driving conditions and load requirements, ensuring the truck operates at peak efficiency 4.

Key Features of the 4354558 ECM

The primary features of the 4354558 ECM include robust processing power, substantial memory capacity, and advanced sensor integration. It employs sophisticated communication protocols to interact with other truck systems, ensuring seamless operation and data exchange. These features contribute to the ECM’s ability to manage complex engine functions effectively 2.

Benefits of Using the 4354558 ECM

Utilizing the 4354558 ECM offers several advantages. It enhances fuel efficiency by optimizing engine operations, leading to cost savings. The ECM also improves engine performance, ensuring the truck operates smoothly under various conditions. Additionally, it reduces emissions by fine-tuning engine parameters, contributing to environmental sustainability. Increased reliability is another benefit, as the ECM monitors and adjusts engine functions to prevent issues and extend component lifespan 3.

Troubleshooting the 4354558 ECM

Identifying and addressing common issues with the 4354558 ECM involves several steps. Diagnostic procedures include using specialized tools to read error codes and monitor system performance. Interpreting these error codes helps pinpoint specific problems, whether they relate to sensor malfunctions, software glitches, or hardware issues. Potential solutions may involve software updates, sensor replacements, or ECM reprogramming, depending on the diagnosed issue 3.

Maintenance Tips for the 4354558 ECM

To ensure optimal performance of the 4354558 ECM, regular inspections are recommended. This includes checking for physical damage, ensuring all connections are secure, and verifying that sensors and actuators are functioning correctly. Software updates should be installed as they become available to maintain the ECM’s efficiency and compatibility with other systems. Preventive measures, such as protecting the ECM from environmental factors and avoiding unnecessary electrical surges, also contribute to its longevity 3.

Integration with Other Systems

The 4354558 ECM interacts with various other truck systems, including the transmission, braking system, and aftermarket devices. It communicates with these systems to ensure coordinated operation, enhancing overall truck performance. For example, the ECM may adjust engine parameters based on transmission load or braking system requirements, ensuring smooth and efficient operation 4.

Upgradability and Future-Proofing

The 4354558 ECM is designed with upgradability in mind. Software updates can be installed to enhance its functionality and adapt to new regulations or performance standards. Additionally, hardware enhancements may be available to future-proof the ECM, ensuring it remains compatible with advancing technologies and continues to deliver optimal performance 4.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its innovative products and commitment to excellence. With a rich history of developing reliable and high-performance engines and components, Cummins continues to push the boundaries of technology. Their product range includes a variety of engines, filtration systems, and power generation equipment, all designed to meet the demanding needs of commercial and industrial applications 4.

Electronic Control Module (Part 4354558) Compatibility with Cummins Engines

The Electronic Control Module (ECM) part number 4354558, manufactured by Cummins, is a critical component in the operation of various Cummins engines. This ECM is designed to manage and control the engine’s performance, ensuring optimal efficiency and reliability. Below is a detailed description of how this ECM fits with the specified engines.

K19 and K38 Engines

The ECM part 4354558 is compatible with both the K19 and K38 engines. These engines are known for their robust performance and are often used in heavy-duty applications. The ECM plays a pivotal role in these engines by regulating fuel injection, ignition timing, and other critical functions. It ensures that the engine operates within its designed parameters, enhancing longevity and performance 4.

K50 Engine

The K50 engine also benefits from the ECM part 4354558. This engine is designed for high-performance applications, and the ECM is integral to its operation. By precisely controlling the engine’s functions, the ECM helps maintain optimal performance levels, ensuring that the K50 engine delivers the power and efficiency required for demanding tasks 4.

V903 Engine

The V903 engine is another model that is compatible with the ECM part 4354558. This engine is typically used in applications where reliability and power are paramount. The ECM ensures that the V903 engine operates smoothly and efficiently, managing various engine parameters to maintain peak performance 4.

Grouping of Engines

The K19, K38, and K50 engines share similar design philosophies and operational requirements, making them suitable for the same ECM. These engines are often used in similar applications, such as heavy-duty trucks and industrial machinery, where reliability and performance are critical. The V903 engine, while distinct in its design, also benefits from the advanced control features provided by the ECM part 4354558, ensuring it operates at its best in various demanding environments 4.

Role of the Electronic Control Module (ECM) in Engine Systems

The Electronic Control Module (ECM) part 4354558 is integral to the operation of modern engine systems. It acts as the brain of the engine, processing data from various sensors and making real-time adjustments to optimize performance, efficiency, and emissions 4.

Fuel Injection System

In fuel-injected engines, the ECM part 4354558 monitors inputs from the mass airflow sensor, throttle position sensor, and oxygen sensors. It calculates the precise amount of fuel needed and controls the fuel injectors to deliver the correct fuel-air mixture. This ensures efficient combustion and reduces fuel consumption 4.

Ignition System

The ECM part 4354558 also manages the ignition system by controlling the spark timing. It receives data from the crankshaft position sensor and camshaft position sensor to determine the optimal timing for spark delivery. This enhances engine performance and reduces emissions 4.

Emission Control System

In conjunction with the emission control system, the ECM part 4354558 regulates the operation of components such as the catalytic converter and the exhaust gas recirculation (EGR) valve. It monitors oxygen sensor readings to adjust the fuel mixture and ensure that emissions remain within regulatory limits 4.

Variable Valve Timing (VVT)

For engines equipped with variable valve timing, the ECM part 4354558 controls the timing of the intake and exhaust valves. By adjusting valve timing based on engine speed and load, it improves engine efficiency, power output, and fuel economy 4.

Turbocharger Control

In turbocharged engines, the ECM part 4354558 manages the turbocharger’s operation. It monitors boost pressure and adjusts the wastegate to maintain optimal turbo speed. This ensures that the engine receives the correct amount of pressurized air, enhancing performance without risking damage 4.

Idle Air Control (IAC)

The ECM part 4354558 also controls the idle air control valve to maintain a stable idle speed. It adjusts the airflow bypassing the throttle plate to keep the engine running smoothly when the vehicle is stationary 4.

Transmission Control

In vehicles with automatic transmissions, the ECM part 4354558 works in tandem with the transmission control module (TCM) to manage gear shifts. It considers factors such as vehicle speed, engine load, and throttle position to ensure smooth and efficient gear changes 4.

Battery and Alternator Management

The ECM part 4354558 monitors the battery’s state of charge and the alternator’s output. It ensures that the electrical system operates within safe parameters, preventing overcharging or undercharging of the battery 4.

Coolant and Air Temperature Management

By receiving data from the engine coolant temperature sensor and the intake air temperature sensor, the ECM part 4354558 adjusts fuel delivery and ignition timing to accommodate varying temperature conditions. This helps maintain optimal engine performance in all operating environments 4.

Diagnostic and Feedback Loop

The ECM part 4354558 continuously performs self-diagnostics and provides feedback to the driver through the onboard diagnostics (OBD) system. It stores trouble codes that can be read by mechanics to identify and address potential issues promptly 4.

Conclusion

The 4354558 Electronic Control Module by Cummins is a sophisticated and integral component in the operation of commercial trucks and various Cummins engines. Its role in optimizing engine performance, managing emissions, and ensuring reliability makes it a critical part of modern engine management systems. Regular maintenance, troubleshooting, and upgradability ensure that this ECM continues to deliver optimal performance and efficiency.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.