4354531

Electronic Control Module

Cummins®

AVAILABLE

9 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4354531 Electronic Control Module (ECM) is a sophisticated component designed for use in commercial trucks. It serves as the central processing unit for the vehicle’s engine management system, ensuring efficient and reliable operation. This ECM is integral to the overall performance of the truck, influencing various aspects such as engine control, emissions management, and vehicle diagnostics.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that manages and controls various functions within a vehicle. It processes data from numerous sensors and actuators, making real-time adjustments to optimize engine performance, fuel efficiency, and emissions. The ECM is a cornerstone of modern vehicle management systems, providing the intelligence needed to adapt to changing driving conditions and regulatory requirements 1.

Purpose of the Cummins 4354531 ECM

The Cummins 4354531 ECM is specifically engineered to manage the engine operations of commercial trucks. It oversees critical functions such as fuel injection timing, air-fuel ratio, and ignition timing. Additionally, it plays a role in emissions control by monitoring and adjusting parameters to meet environmental standards. The ECM also contributes to overall vehicle performance by ensuring smooth operation and responsiveness under various load conditions 2.

Key Features

The Cummins 4354531 ECM boasts several notable features. It is equipped with advanced processing power and substantial memory capacity, allowing it to handle complex calculations and store extensive data logs. The module offers robust connectivity options, facilitating communication with other vehicle systems and diagnostic tools. It incorporates unique technological advancements, such as enhanced diagnostic capabilities and real-time data processing, to provide superior engine management.

Benefits of Using the Cummins 4354531 ECM

Utilizing the Cummins 4354531 ECM offers several advantages. It contributes to improved fuel efficiency by optimizing engine operations, leading to cost savings for fleet operators. The ECM enhances engine performance, ensuring consistent power delivery and responsiveness. It also plays a role in better emissions control, helping vehicles comply with stringent environmental regulations. Furthermore, the ECM increases the reliability of the truck by continuously monitoring and adjusting engine parameters to prevent potential issues.

Integration with Other Systems

The Cummins 4354531 ECM is designed to interact seamlessly with other truck systems. It communicates with the transmission to ensure smooth gear changes and optimal power delivery. The ECM also works in conjunction with the braking system to enhance safety and performance. Additionally, it interfaces with diagnostic tools to provide comprehensive vehicle health reports, aiding in maintenance and troubleshooting efforts.

Programming and Updates

Programming the Cummins 4354531 ECM involves configuring the module to match the specific requirements of the truck’s engine and operating conditions. Updates are managed through software patches that can be installed via diagnostic tools. Keeping the ECM up to date is important for maintaining optimal performance and compliance with the latest emissions standards. The update process typically involves downloading the latest software from Cummins and applying it to the ECM using specialized equipment.

Troubleshooting Common Issues

Common issues with the Cummins 4354531 ECM may include error codes, performance anomalies, and connectivity problems. Identifying these issues often involves using diagnostic tools to read error codes stored in the ECM. Addressing performance issues may require reprogramming the ECM or adjusting settings to optimize engine operation. Connectivity problems can sometimes be resolved by checking physical connections or updating the ECM’s software.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4354531 ECM, regular maintenance is recommended. This includes performing routine checks to ensure all connections are secure and the module is functioning correctly. Cleaning the ECM and its surroundings can prevent dust and debris from affecting its operation. Additionally, staying informed about software updates and applying them as needed can help maintain the ECM’s performance and compatibility with other systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, catering to various applications and industries. Cummins’ commitment to innovation and quality has solidified its position as a leader in the market.

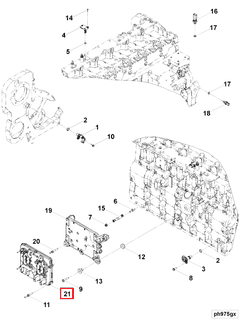

Role of Part 4354531 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM), part 4354531, is integral to the operation and management of modern engine systems. It serves as the central processing unit, orchestrating the communication and coordination between various engine components to ensure optimal performance and efficiency.

Integration with Engine Control Module (ECM)

The ECM, part 4354531, works in tandem with the Engine Control Module to regulate fuel injection, ignition timing, and emissions control. It processes data from sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors. By analyzing this data, the ECM adjusts the fuel-air mixture and ignition timing in real-time, enhancing engine performance and fuel efficiency.

Interaction with Electronic Service Calibration

Electronic Service Calibration (ESC) is another component where the ECM, part 4354531, plays a significant role. The ESC system relies on the ECM to store calibration data that fine-tunes engine parameters based on specific operating conditions. This calibration ensures that the engine operates within optimal parameters, reducing wear and tear, and prolonging the engine’s lifespan. The ECM facilitates the update and recalibration processes, allowing for adjustments to be made as needed to maintain peak performance.

Communication with Other Sensors and Actuators

The ECM, part 4354531, communicates with a variety of sensors and actuators throughout the engine system. It receives input from the Camshaft Position Sensor (CMP) and Crankshaft Position Sensor (CKP) to monitor engine speed and position. Based on this information, the ECM controls actuators such as the fuel injectors, idle air control valve, and variable valve timing (VVT) system to optimize engine operation.

Role in Emissions Control

In the context of emissions control, the ECM, part 4354531, is responsible for managing the Exhaust Gas Recirculation (EGR) system and the catalytic converter. It monitors the exhaust gas temperature and oxygen levels, making necessary adjustments to minimize harmful emissions while maintaining engine performance. This ensures compliance with environmental regulations and reduces the engine’s environmental impact.

Enhancing Driveability and Performance

Finally, the ECM, part 4354531, enhances driveability by managing the transmission control module (TCM) in automated manual transmissions. It ensures smooth gear shifts and optimal power delivery by coordinating with the TCM based on driving conditions and driver input. This results in a more responsive and enjoyable driving experience.

Conclusion

The Cummins 4354531 ECM is a pivotal component in modern engine systems, ensuring that all aspects of engine operation are finely tuned for performance, efficiency, and compliance with emissions standards. Its advanced features, integration capabilities, and role in emissions control make it an essential part of the engine management system in commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.