This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

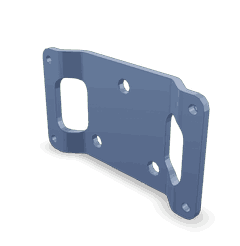

The Electronic Control Module Bracket (Part #4323384) by Cummins is designed to support and secure the Electronic Control Module (ECM) in heavy-duty trucks. This part is integral to the truck’s electronic system, ensuring the ECM remains stable and protected. Cummins, a renowned manufacturer in the commercial truck industry, produces this bracket, leveraging its extensive expertise and commitment to quality 1.

Function and Operation

This Cummins part plays a role in the operation of a truck by providing a secure mounting point for the ECM. It facilitates the ECM’s interaction with various truck components by ensuring it remains firmly in place. The ECM, which manages the truck’s electronic systems, relies on the bracket to maintain its position and functionality amidst the vibrations and movements inherent in truck operations 2.

Key Features

The design of the Electronic Control Module Bracket incorporates several characteristics that enhance its performance and durability. Constructed from high-strength materials, the bracket is engineered to withstand the rigors of heavy-duty truck environments. It features precise mounting provisions that ensure a secure fit, and it is designed to be compatible with a range of Cummins engines. These features contribute to the bracket’s reliability and effectiveness in supporting the ECM 3.

Benefits

The Electronic Control Module Bracket offers several advantages that contribute to the overall performance and maintenance of heavy-duty trucks. By providing a stable mounting solution for the ECM, it enhances the module’s protection against physical damage and environmental factors. Additionally, the bracket aids in thermal management by allowing for proper airflow around the ECM, which helps in dissipating heat generated during operation. The design of the bracket also simplifies the installation process, reducing the time and effort required for setup.

Installation and Maintenance

Proper installation of the Electronic Control Module Bracket is vital for ensuring its effectiveness and the ECM’s performance. Installation guidelines recommend following torque specifications to secure the bracket without over-tightening, which could damage the mounting surface or the bracket itself. Alignment checks should be performed to confirm that the bracket is level and properly positioned relative to the ECM and other components. Regular maintenance, including inspections for signs of wear or damage, can help ensure the longevity and optimal performance of the bracket.

Troubleshooting Common Issues

Common issues associated with the Electronic Control Module Bracket may include mounting problems or ECM overheating. If the bracket becomes loose, it should be re-secured according to the installation guidelines to prevent further issues. In cases of ECM overheating, checking the bracket’s alignment and ensuring proper airflow around the ECM can help mitigate the problem. Regular inspections and maintenance can preemptively address potential issues, ensuring the bracket and ECM operate efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance products. The company’s extensive product range and commitment to innovation and quality have made it a preferred choice among truck manufacturers and operators worldwide.

Compatibility with Cummins Engines

The ECM Bracket 4323384 is engineered to fit seamlessly with several Cummins engine models, including:

- QST30

- CM2350

- T101

These engines are known for their robust performance and efficiency, often used in a variety of applications ranging from industrial to marine settings. The bracket’s design ensures it can adapt to the specific mounting requirements of each engine type, providing a stable and secure platform for the ECM.

Installation and Functionality

When installing the ECM Bracket 4323384, it is crucial to follow the manufacturer’s guidelines to ensure proper alignment and secure attachment. This bracket not only supports the ECM but also protects it from environmental factors that could affect its performance.

By using the correct bracket, engine operators can maintain the integrity of the ECM, which is essential for the engine’s overall control and monitoring systems. This ensures that the engine runs smoothly and efficiently, reducing the likelihood of unexpected downtimes and maintenance issues.

Role of Part 4323384 Electronic Control Module Bracket in Engine Systems

The Electronic Control Module (ECM) Bracket, identified by part number 4323384, serves as a foundational component in the integration and operation of various engine systems. This bracket is engineered to securely mount the ECM, ensuring it remains stable and protected within the engine compartment.

Integration with Engine Control Module (ECM)

The ECM is the brain of the engine system, responsible for processing data from various sensors and making real-time adjustments to engine performance. The 4323384 bracket provides a stable platform for the ECM, allowing it to interface effectively with other components such as the engine control unit and fuel control module. This secure mounting is essential for maintaining the integrity of the electrical connections and protecting the ECM from physical damage and environmental factors.

Connection to Engine Control Unit

The engine control unit (ECU) works in tandem with the ECM to manage engine operations. The 4323384 bracket ensures that the ECM is positioned optimally to communicate with the ECU. This communication is vital for the ECU to receive processed data from the ECM and execute commands that regulate fuel injection, ignition timing, and other critical functions. The bracket’s design facilitates easy access for maintenance and troubleshooting, enhancing the overall reliability of the engine system.

Fuel Control Module Interaction

In fuel-injected engines, the fuel control module plays a significant role in regulating the fuel supply to the engine. The ECM, mounted on the 4323384 bracket, processes input from various sensors to determine the appropriate fuel delivery. The stable mounting provided by the bracket ensures that the ECM can accurately send signals to the fuel control module, resulting in precise fuel management and optimal engine performance.

Overall System Stability

The 4323384 bracket contributes to the overall stability of the engine control system by providing a robust mounting solution for the ECM. This stability is particularly important in high-vibration environments typical of engine compartments. By securing the ECM, the bracket helps maintain the reliability and efficiency of the engine control and fuel control systems, ensuring smooth and consistent engine operation.

Conclusion

The Electronic Control Module Bracket (Part #4323384) by Cummins is a critical component for the reliable operation of heavy-duty trucks. Its design ensures the ECM remains securely mounted, protected, and capable of interfacing with other engine components effectively. Proper installation and maintenance of this part are essential for the optimal performance and longevity of the truck’s electronic systems.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.