This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4323034 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a well-established name in the commercial truck industry. This wiring harness is integral to the operation of commercial trucks, facilitating the communication and power distribution necessary for the truck’s electronic systems to function efficiently.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires and connectors that link various electronic components within a truck’s electrical system. It includes insulated wires, connectors, terminals, and sometimes fuses or relays. The harness serves as the conduit for electrical signals and power, enabling the Electronic Control Module (ECM) to communicate with and control other electronic components in the vehicle 1.

Purpose of the 4323034 Electronic Control Module Wiring Harness

The 4323034 Electronic Control Module Wiring Harness plays a role in the operation of a truck by providing the necessary connections between the ECM and other electronic systems. It ensures that signals and power are correctly routed, allowing the ECM to monitor and adjust various functions such as engine performance, transmission operations, and emissions controls. This interaction is vital for the truck’s overall performance and efficiency 2.

Key Features

The 4323034 Electronic Control Module Wiring Harness is designed with several features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to the harsh conditions often encountered in commercial trucking environments. The design includes robust connectors and terminals that ensure secure and reliable connections. Additionally, the harness may incorporate unique attributes such as enhanced shielding to protect against electromagnetic interference, contributing to its overall effectiveness.

Benefits

The 4323034 Electronic Control Module Wiring Harness offers several benefits. It contributes to improved reliability by ensuring stable and consistent electrical connections. This reliability is crucial for the efficient operation of the truck’s electronic systems. Furthermore, the harness supports the integration of modern truck technologies, enhancing the vehicle’s performance and efficiency. Its design also aids in simplifying the installation process, reducing the potential for errors and ensuring a more straightforward integration into the truck’s electrical system 3.

Installation Process

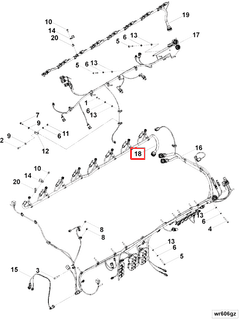

Installing the 4323034 Electronic Control Module Wiring Harness involves several steps to ensure proper integration into the truck’s electrical system. Begin by identifying the correct location for the harness within the vehicle. Carefully route the wires to avoid sharp edges or moving parts that could cause damage. Secure the harness in place using the provided mounting brackets or ties. Connect the harness to the ECM and other electronic components, ensuring that all connections are secure and correctly aligned. Finally, test the system to confirm that all connections are functioning as intended and that there are no issues with signal transmission or power distribution.

Troubleshooting and Maintenance

To troubleshoot common issues with the 4323034 Electronic Control Module Wiring Harness, start by checking for visible signs of damage such as frayed wires or loose connections. Ensure that all connectors are securely attached and that there is no corrosion present. If issues persist, use a multimeter to test for continuity and proper voltage levels. Regular maintenance involves inspecting the harness for signs of wear or damage, cleaning connectors to prevent corrosion, and ensuring that all connections remain tight and secure. This proactive approach helps to maintain the harness’s performance and longevity.

About Cummins

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history spanning several decades, Cummins has established itself as a leader in engine and powertrain technology. The company’s product range includes engines, filtration systems, powertrain components, and emission solutions, all designed to meet the demanding requirements of commercial trucking. Cummins’ commitment to innovation and customer satisfaction has solidified its position as a trusted partner in the industry.

Cummins Electronic Control Module Wiring Harness (Part 4323034)

The Cummins Electronic Control Module (ECM) Wiring Harness, identified by part number 4323034, is a critical component in the electrical systems of various Cummins engines. This wiring harness is designed to ensure seamless communication and power distribution between the ECM and other electronic control units within the engine.

Compatibility with Cummins Engines

The ECM Wiring Harness 4323034 is engineered to fit seamlessly with several Cummins engine models, including:

-

QSK50: This engine is known for its robust performance and reliability, often used in heavy-duty applications such as marine and industrial settings. The wiring harness ensures that the ECM can effectively manage engine operations, optimizing performance and efficiency.

-

CM2150: This engine is typically employed in on-highway and vocational applications. The harness is designed to handle the specific electrical demands of this engine, ensuring that all electronic components are properly connected and functioning.

-

K107: This engine is part of the K Series, which is widely used in various applications, including construction and agricultural equipment. The wiring harness is tailored to meet the electrical needs of the K107, facilitating smooth and reliable engine operation.

Grouping of Engines

The ECM Wiring Harness 4323034 is particularly well-suited for engines that require precise and reliable electronic control. By grouping the QSK50, CM2150, and K107 engines, it is evident that this wiring harness is designed to support a range of applications, from marine and industrial to on-highway and vocational uses. The commonality among these engines is the need for an efficient and dependable electrical system, which the wiring harness provides.

Application Considerations

When installing the ECM Wiring Harness 4323034, it is essential to ensure that all connections are secure and that the harness is properly routed to avoid interference with other components. This will help maintain the integrity of the electrical system and ensure that the ECM can perform its functions without interruption.

Proper installation and maintenance of the wiring harness are crucial for the longevity and performance of the engine, as it directly impacts the engine’s ability to communicate with and control various electronic systems.

Role of Part 4323034 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified as part 4323034, serves as the vital link between the ECM and various engine components. This harness facilitates the transmission of electrical signals and power necessary for the ECM to monitor and control engine operations effectively.

Integration with Engine Components

-

Sensors: The harness connects various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor to the ECM. These sensors provide real-time data on air intake, oxygen levels, and pressure within the intake manifold, allowing the ECM to make precise adjustments to fuel delivery and ignition timing.

-

Actuators: It interfaces with actuators including the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. The ECM uses the harness to send control signals that regulate fuel injection timing, throttle position, and valve timing, optimizing engine performance and efficiency.

-

Ignition System: The harness is responsible for connecting the ECM to the ignition coil(s) and spark plugs. It ensures that the ECM can control the ignition timing with precision, enhancing combustion efficiency and reducing emissions.

-

Emission Control Systems: It links the ECM to components of the emission control system, such as the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. This connection allows the ECM to manage emissions by controlling the recirculation of exhaust gases and monitoring the efficiency of the catalytic converter.

-

Battery and Alternator: The harness also provides the necessary connections for the ECM to interface with the vehicle’s battery and alternator. This ensures that the ECM receives a stable power supply and can monitor the charging system to maintain optimal battery health.

-

Communication Networks: In modern vehicles, the ECM Wiring Harness often includes connections to the Controller Area Network (CAN) bus. This allows the ECM to communicate with other control modules in the vehicle, facilitating integrated system management and diagnostics.

By seamlessly integrating these components, the ECM Wiring Harness ensures that the ECM can effectively manage and optimize engine performance, fuel efficiency, and emissions control.

Conclusion

The 4323034 Electronic Control Module Wiring Harness is a critical component in the electrical systems of Cummins engines, ensuring seamless communication and power distribution between the ECM and other electronic control units. Its design and features contribute to the reliability, performance, and efficiency of the engine systems it supports. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and optimal performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.