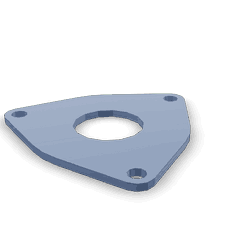

4314467

Coolant Flow Metering Orifice

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Coolant Flow Metering Orifice Assembly, identified by part number 4314467, is a component manufactured by Cummins. This assembly is integral to the cooling systems of heavy-duty trucks, ensuring efficient coolant flow and temperature regulation. Cummins, a reputable name in the automotive industry, is known for its commitment to innovation and quality in manufacturing automotive components 1.

Basic Concepts

Coolant flow metering is a process that involves regulating the flow of coolant through the engine cooling system to maintain optimal operating temperatures. Orifice assemblies play a role in this system by controlling the rate at which coolant passes through specific points. The Coolant Flow Metering Orifice Assembly is designed to precisely manage coolant flow, contributing to the overall efficiency and reliability of the cooling system 2.

Purpose and Function

The Coolant Flow Metering Orifice Assembly serves to maintain optimal coolant flow rates and temperatures within a truck’s cooling system. By regulating the flow of coolant, it helps ensure that the engine operates within its designed temperature range, which is crucial for performance and longevity. This assembly is positioned in the coolant pathway to offer resistance, thereby controlling the flow rate and preventing overheating 3.

Key Features

The Coolant Flow Metering Orifice Assembly is characterized by its precise design and the materials used in its construction. Typically made from durable materials resistant to corrosion and high temperatures, this assembly is engineered to withstand the demanding conditions of heavy-duty truck operations. Its design includes specific orifice sizes and shapes that are tailored to the requirements of the cooling system it serves, ensuring accurate flow metering.

Benefits

Utilizing the Coolant Flow Metering Orifice Assembly offers several advantages. It contributes to improved engine cooling efficiency by ensuring that coolant is distributed evenly and at the correct rate. This leads to enhanced engine reliability and can result in potential cost savings for fleet operators by reducing the risk of engine damage due to overheating. Additionally, the assembly’s durable construction minimizes the need for frequent replacements, further contributing to cost efficiency.

Installation and Compatibility

Proper installation of the Coolant Flow Metering Orifice Assembly is vital for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure compatibility with the specific truck model and engine type. Attention to detail during installation helps prevent issues such as coolant leaks or improper flow rates, which could affect the cooling system’s performance.

Maintenance and Troubleshooting

To ensure the Coolant Flow Metering Orifice Assembly operates optimally, regular maintenance is recommended. This includes checking for signs of wear or damage, ensuring there are no obstructions in the coolant pathway, and verifying that the assembly is securely installed. Common troubleshooting techniques for issues like coolant leaks or flow restrictions involve inspecting the assembly for blockages or damage and ensuring it is correctly positioned within the system.

Cummins Overview

Cummins is a well-established company in the automotive industry, known for its innovative approaches and quality manufacturing processes. With a history of producing reliable and high-performance components, Cummins has built a reputation for excellence. The company’s commitment to innovation is evident in its product line, which includes a wide range of automotive components designed to meet the rigorous demands of modern vehicles.

Coolant Flow Metering Orifice Assembly (Part 4314467) in Cummins Engines

The Coolant Flow Metering Orifice Assembly, part number 4314467, is a critical component in the cooling systems of various Cummins engines. This part is designed to regulate the flow of coolant, ensuring optimal engine performance and longevity.

QSK60 Engine

In the QSK60 engine, the Coolant Flow Metering Orifice Assembly plays a pivotal role in maintaining the coolant flow rate. This engine, known for its robust design and high power output, benefits from the precise regulation provided by this assembly. The assembly ensures that the coolant circulates at the correct rate, preventing overheating and maintaining the engine’s efficiency.

CM850 Engine

The CM850 engine also relies on the Coolant Flow Metering Orifice Assembly to manage coolant flow. This engine, typically used in heavy-duty applications, requires a reliable and efficient cooling system to handle the demands of continuous operation. The assembly’s role in this engine is to maintain the coolant flow at optimal levels, contributing to the engine’s overall performance and durability.

MCRS Engine

In the MCRS engine, the Coolant Flow Metering Orifice Assembly is integral to the engine’s cooling system. This engine, often found in marine applications, demands a cooling system that can operate under varying conditions. The assembly ensures that the coolant flow is consistent, providing the necessary cooling to the engine components and preventing thermal stress.

Grouping of Engines

The Coolant Flow Metering Orifice Assembly is a versatile component that fits seamlessly into the cooling systems of the QSK60, CM850, and MCRS engines. Each of these engines, while differing in application and design, shares the common requirement of maintaining an optimal coolant flow rate. The assembly’s role in these engines is to ensure that the coolant circulates efficiently, contributing to the engine’s performance, reliability, and longevity.

Role of 4314467 Coolant Flow Metering Orifice Assembly in Engine Systems

The 4314467 Coolant Flow Metering Orifice Assembly is an essential component in the coolant system of an engine, working in conjunction with several other parts to ensure optimal engine performance and longevity.

Integration with Plumbing

In the engine’s coolant system, the plumbing consists of a network of hoses, pipes, and fittings that transport coolant throughout the engine. The Coolant Flow Metering Orifice Assembly is strategically placed within this network to regulate the flow of coolant. By controlling the rate at which coolant passes through specific pathways, it helps maintain consistent coolant pressure and temperature. This regulation is vital for preventing overheating and ensuring that all engine components receive adequate cooling.

Interaction with Thermostat Housing

The thermostat housing is another key component in the coolant system, housing the thermostat which controls the flow of coolant based on engine temperature. The Coolant Flow Metering Orifice Assembly works in tandem with the thermostat housing to fine-tune coolant flow. When the engine is cold, the thermostat restricts coolant flow to allow the engine to reach operating temperature more quickly. As the engine warms up, the thermostat opens, allowing coolant to flow through the system. The orifice assembly further modulates this flow, ensuring that coolant circulates efficiently even as the thermostat adjusts. This collaboration helps in maintaining a stable engine temperature, which is essential for efficient combustion and reduced wear on engine components.

By precisely metering coolant flow, the 4314467 Coolant Flow Metering Orifice Assembly plays a significant role in the overall efficiency and reliability of the engine’s cooling system.

Conclusion

The Coolant Flow Metering Orifice Assembly, part number 4314467, is a vital component in the cooling systems of heavy-duty trucks and Cummins engines. Its precise design and durable construction ensure efficient coolant flow and temperature regulation, contributing to engine performance and longevity. Proper installation, maintenance, and understanding of its role within the engine’s cooling system are essential for maximizing its benefits.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.