This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Coolant Flow Metering Orifice (Part #4314438) by Cummins is a component designed to regulate coolant flow within heavy-duty truck engines. Cummins, a well-established manufacturer in the automotive industry, produces this part to enhance the efficiency and reliability of engine cooling systems. This orifice plays a role in maintaining optimal engine temperature, which is vital for the performance and longevity of heavy-duty engines.

Basic Concepts

Coolant flow metering orifices are integral to the engine cooling system. Their primary function is to manage the flow of coolant through the engine, ensuring that the temperature remains within specified limits. Precise coolant flow management is important for preventing engine overheating, which can lead to reduced efficiency and potential damage. The orifice achieves this by controlling the rate at which coolant passes through specific points in the cooling system, thereby maintaining a consistent and optimal flow 1.

Purpose and Function

The Coolant Flow Metering Orifice (Part #4314438) serves to regulate coolant flow in truck engines, playing a role in maintaining optimal engine temperature and efficiency. By controlling the flow of coolant, this component helps to dissipate heat generated during engine operation. This regulation ensures that the engine operates within its designed temperature range, which is important for both performance and durability. The orifice is positioned in the coolant pathway to provide consistent flow rates, adapting to the engine’s varying thermal demands 2.

Key Features

The Coolant Flow Metering Orifice is characterized by its precise design and the materials used in its construction. Typically made from durable materials such as brass or stainless steel, this orifice is engineered to withstand the high temperatures and pressures within the engine cooling system. Its design includes specific dimensions and flow characteristics tailored to the requirements of heavy-duty engines. These features enhance its performance and durability, ensuring reliable operation over the engine’s lifespan.

Benefits

Using the Coolant Flow Metering Orifice in heavy-duty truck engines offers several benefits. Improved engine performance is one of the primary advantages, as consistent coolant flow helps maintain optimal engine temperature. This, in turn, enhances the engine’s efficiency and reliability. Additionally, precise coolant flow regulation can lead to potential cost savings through efficient maintenance, as it reduces the risk of engine overheating and related damages. The orifice also contributes to the overall longevity of the engine by ensuring that it operates within safe temperature limits 3.

Installation and Integration

Proper installation of the Coolant Flow Metering Orifice is important for its effective function within the engine cooling system. It is important to follow manufacturer guidelines to ensure compatibility with various engine models and cooling system configurations. The orifice should be installed in the designated location within the coolant pathway, ensuring a secure fit and proper alignment. This will facilitate optimal coolant flow and temperature regulation, contributing to the engine’s efficient operation.

Troubleshooting and Maintenance

Common issues related to the Coolant Flow Metering Orifice may include coolant leaks or flow restrictions. Regular inspection and maintenance are recommended to identify and address these problems promptly. Maintenance tips include checking for signs of wear or corrosion, ensuring that the orifice is securely installed, and verifying that there are no obstructions in the coolant pathway. Addressing these issues promptly can help maintain the orifice’s performance and longevity, contributing to the overall efficiency of the engine cooling system.

Cummins Overview

Cummins is a reputable manufacturer in the automotive industry, known for its high-quality engine components. With a history of innovation and commitment to excellence, Cummins has established itself as a leader in the production of reliable and efficient engine parts. The company’s dedication to manufacturing excellence is evident in its wide range of products, including the Coolant Flow Metering Orifice, which is designed to meet the demanding requirements of heavy-duty truck engines.

Cummins Coolant Flow Metering Orifice 4314438 in Engine Applications

The Cummins Coolant Flow Metering Orifice 4314438 is an integral component in the cooling systems of several Cummins engines, ensuring optimal coolant flow and temperature regulation. This part is specifically designed to fit seamlessly into the engine architecture of the QSK19, CM850, and MCRS engines, enhancing their overall performance and longevity.

In the QSK19 engine, the Coolant Flow Metering Orifice 4314438 plays a role in maintaining the precise coolant flow necessary for efficient engine operation. This engine, known for its robust performance, benefits from the accurate flow metering provided by this component, ensuring that the engine remains within its optimal temperature range even under heavy loads.

Similarly, in the CM850 engine, the Coolant Flow Metering Orifice 4314438 is important for maintaining the delicate balance of coolant flow. This engine, designed for versatility and reliability, relies on this part to prevent overheating and ensure consistent performance across various applications.

The MCRS engine also integrates the Coolant Flow Metering Orifice 4314438 to enhance its cooling system’s efficiency. This engine, known for its adaptability and durability, uses this component to manage coolant flow effectively, contributing to its overall reliability and performance.

Together, these engines benefit from the precise flow control provided by the Cummins Coolant Flow Metering Orifice 4314438, ensuring that each engine operates at peak efficiency and reliability.

Role of Part 4314438 Coolant Flow Metering Orifice in Engine Systems

The Part 4314438 Coolant Flow Metering Orifice is a component in the regulation and monitoring of coolant flow within engine systems. Its primary function is to ensure precise measurement and control of coolant as it circulates through various components.

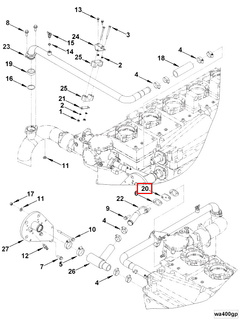

Integration with Plumbing Systems

In plumbing systems associated with engine cooling, the Coolant Flow Metering Orifice is strategically placed to monitor the flow rate of coolant. This component works in conjunction with sensors and control units to provide real-time data on coolant movement. By doing so, it helps maintain optimal coolant levels and flow rates, which are vital for efficient heat dissipation and engine performance. The orifice allows for fine-tuning of the coolant system, ensuring that all engine parts receive consistent cooling, thereby enhancing overall system reliability.

Function in Aftercooler Water Systems

When integrated into aftercooler water systems, the Coolant Flow Metering Orifice plays a role in enhancing the efficiency of the aftercooling process. Aftercoolers are designed to reduce the temperature of compressed air, and the effective flow of coolant is important to this function. The orifice ensures that the coolant flow is metered accurately, allowing the aftercooler to operate within specified parameters. This results in improved air quality and temperature control, which directly contributes to better engine performance and longevity. The precise measurement of coolant flow also aids in the early detection of potential issues, such as blockages or leaks, allowing for timely maintenance and preventing more severe problems down the line.

Conclusion

The Coolant Flow Metering Orifice (Part #4314438) by Cummins is a critical component in the efficient operation of heavy-duty truck engines. By regulating coolant flow, this part ensures that engines maintain optimal temperature, enhancing performance, reliability, and longevity. Proper installation, regular maintenance, and understanding its role in various engine systems are key to maximizing the benefits of this component.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.