4310447

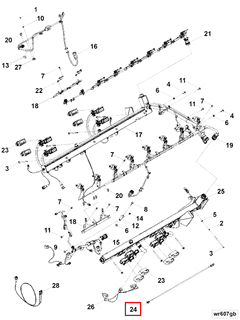

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4310447 Electronic Control Module Wiring Harness is a component designed by Cummins to facilitate the operation of commercial trucks. This wiring harness is integral to the electrical system of trucks, ensuring seamless communication between the Electronic Control Module (ECM) and various sensors and actuators. Cummins, a renowned manufacturer in the commercial truck industry, produces this wiring harness with a focus on reliability and performance 2.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to different sensors and actuators within a truck’s electrical system. This harness plays a role in transmitting signals and power between the ECM and other electronic components, enabling the ECM to monitor and control various functions of the truck. The components of the wiring harness include wires, connectors, and protective sheathing, all designed to withstand the demanding conditions of commercial truck operations 1.

Purpose of the 4310447 Electronic Control Module Wiring Harness

The 4310447 Wiring Harness is specifically designed to enhance the operation of commercial trucks by facilitating efficient communication between the ECM and other electronic components. It ensures that the ECM receives accurate data from sensors and can send appropriate signals to actuators, thereby playing a role in the overall performance and reliability of the truck’s electronic systems.

Key Features

The 4310447 Wiring Harness is characterized by several key features that contribute to its effectiveness and longevity. These include durability, which allows it to withstand the harsh environmental conditions often encountered in commercial trucking. It also exhibits resistance to environmental factors such as moisture, heat, and vibration. Additionally, the harness is designed for easy installation and maintenance, featuring user-friendly connectors and a layout that simplifies access for repairs and upgrades.

Benefits

The 4310447 Wiring Harness offers several benefits to truck operators. It contributes to the improved reliability of the truck’s electronic systems by ensuring stable and consistent communication between the ECM and other components. This can lead to enhanced performance of the truck, as the ECM can more effectively manage engine functions, transmission shifts, and other critical operations. Furthermore, the harness supports better diagnostics, potentially reducing downtime by enabling more accurate and timely identification of issues.

Installation Considerations

Proper installation of the 4310447 Wiring Harness is vital to its performance and the overall reliability of the truck’s electronic system. It is important to ensure compatibility with specific truck models to guarantee optimal function. Following manufacturer instructions during installation is crucial, as it helps avoid common pitfalls that could lead to connectivity issues or damage to the harness.

Troubleshooting Common Issues

Common issues with the 4310447 Wiring Harness may include connectivity problems or damage from environmental factors. To address these issues, a step-by-step troubleshooting guide can be followed. This involves checking for loose connections, inspecting the harness for signs of wear or damage, and ensuring that all components are correctly installed and functioning as intended.

Maintenance Tips

Regular maintenance of the 4310447 Wiring Harness is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, damage, or corrosion, and cleaning the harness to remove any debris that could interfere with its function. Adhering to a maintenance schedule helps prevent issues before they become critical, contributing to the overall reliability of the truck’s electronic system.

Safety Precautions

When working with the 4310447 Wiring Harness, it is important to follow safety guidelines to protect both the technician and the equipment. This includes disconnecting the battery before performing any maintenance or repairs to prevent electrical shocks or damage to the harness. Additionally, using the appropriate tools and following manufacturer instructions can help ensure a safe and effective maintenance or repair process.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of innovation and expertise in diesel engines and components. The company’s reputation is built on a commitment to quality, reliability, and performance, making it a trusted name among truck operators and manufacturers alike. Cummins’ extensive experience and dedication to advancing technology in the trucking industry underscore the quality and effectiveness of its products, including the 4310447 Electronic Control Module Wiring Harness 2.

Compatibility of Cummins Part 4310447 with QSK19 Engines

The Electronic Control Module Wiring Harness, part number 4310447, manufactured by Cummins, is designed to be compatible with several models of the QSK19 engine series. Specifically, this wiring harness fits seamlessly with the following engine variants:

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK50 CM2350 K108

These engines are part of Cummins’ extensive lineup, known for their robust performance and reliability in various industrial applications. The wiring harness is engineered to ensure efficient and reliable electrical connections within the engine’s control systems, facilitating optimal performance and diagnostics.

The compatibility of part 4310447 across these engine models underscores Cummins’ commitment to providing standardized components that can be easily integrated across different engine configurations, thereby simplifying maintenance and repair processes.

Role of Part 4310447 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, specifically part 4310447, serves as the vital connective tissue within an engine system, ensuring seamless communication and power distribution among various components. This harness is integral to the operation of the Engine Control Module (ECM), which is the brain of the engine system, responsible for regulating and optimizing engine performance.

Integration with Key Components

-

Engine Control Module (ECM): The ECM Wiring Harness directly interfaces with the ECM, facilitating the transmission of data and electrical signals necessary for the ECM to monitor and adjust engine operations in real-time. This includes regulating fuel injection, ignition timing, and emissions controls.

-

Compressor: In systems where a compressor is utilized, such as in air conditioning or turbocharging applications, the ECM Wiring Harness plays a role in controlling the compressor’s operation. It ensures that the compressor engages and disengages as required, based on the ECM’s calculations to maintain optimal engine performance and efficiency.

-

Air System: The harness is also connected to various sensors within the air intake system, such as mass airflow sensors and oxygen sensors. These sensors provide the ECM with data on air quality and quantity, allowing the ECM to make precise adjustments to fuel delivery and ignition timing for efficient combustion.

-

Harness Network: Beyond its direct connections, the ECM Wiring Harness is part of a larger network of wiring harnesses within the engine system. It communicates with other modules and components, ensuring that all parts of the engine system work in harmony. This includes interactions with the transmission control module, anti-lock braking system module, and other ancillary systems that contribute to the overall vehicle performance.

Operational Synergy

The ECM Wiring Harness, through its connections and data transmission capabilities, enables the ECM to execute its role effectively. It ensures that all components within the engine system—from the compressor to the air intake sensors—operate in sync with each other. This coordination is essential for achieving optimal engine performance, fuel efficiency, and emissions compliance.

Conclusion

In summary, part 4310447 Electronic Control Module Wiring Harness is a foundational component in the engine system, facilitating the intricate dance of data and power that allows modern engines to operate at peak efficiency. Its role in connecting and enabling communication among various engine components underscores its importance in the overall functionality and performance of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.